Functional Description 9820/9830/9835 Service Manual

July 1998 TC9830SM Rev. B 7/98 Confidential 11

Ribbon Spool Drive Motors

wo DC ribbon drive motors are mounded to the back

of the module wall. Each motor drives a ribbon spool.

The motors are connected directly to the Control

Board Assembly via separate two-wire harness.

Supply Deflector and Bi-Cell Emitter

(IR LED)

See Chapter 8, “Supply Sensing Systems” for more

information.

Ribbon Transfer Rollers

The two ribbon transfer rollers allow ribbon tension

adjustments. Each roller has an eccentric which

allows slight skew adjustments to each, which in turn

affects the ribbon tension.

Functional Description

The print module, performs ribbon drive operations,

provides mechanical ribbon tension adjustments,

performs print functions, helps maintain supplies

tracking, and houses half of the sensor assembly. It is

controlled by the Control Board Assembly.

Ribbon Drive Operation

The ribbon drive operation is made up of two ribbon

spools, two 25Vdc drive motors, and two ribbon

transfer rollers. It is controlled by the Control Board

Assy. Each drive motor sends continuous information

to the Control Board Assy. where it is used to evaluate

ribbon conditions, maintain optimum ribbon tension,

and sense the end of ribbon condition. This system

eliminates the need for ribbon sensors.

Printing

The printhead has a line array of 832 dot elements

sized to produce 203 dots per inch. Printing occurs by

sending image data to the printhead one line at a

time. Each time a line of data is received,

corresponding dots on the printhead are heated to

create an image line on the stock. Successive image

lines generated across moving stock make up the total

image. The Control Board Assy. controls all image

data sent to the printhead, and regulates the energy

level of the printhead. Energy levels are raised and

lowered to create darker or lighter print respectively.

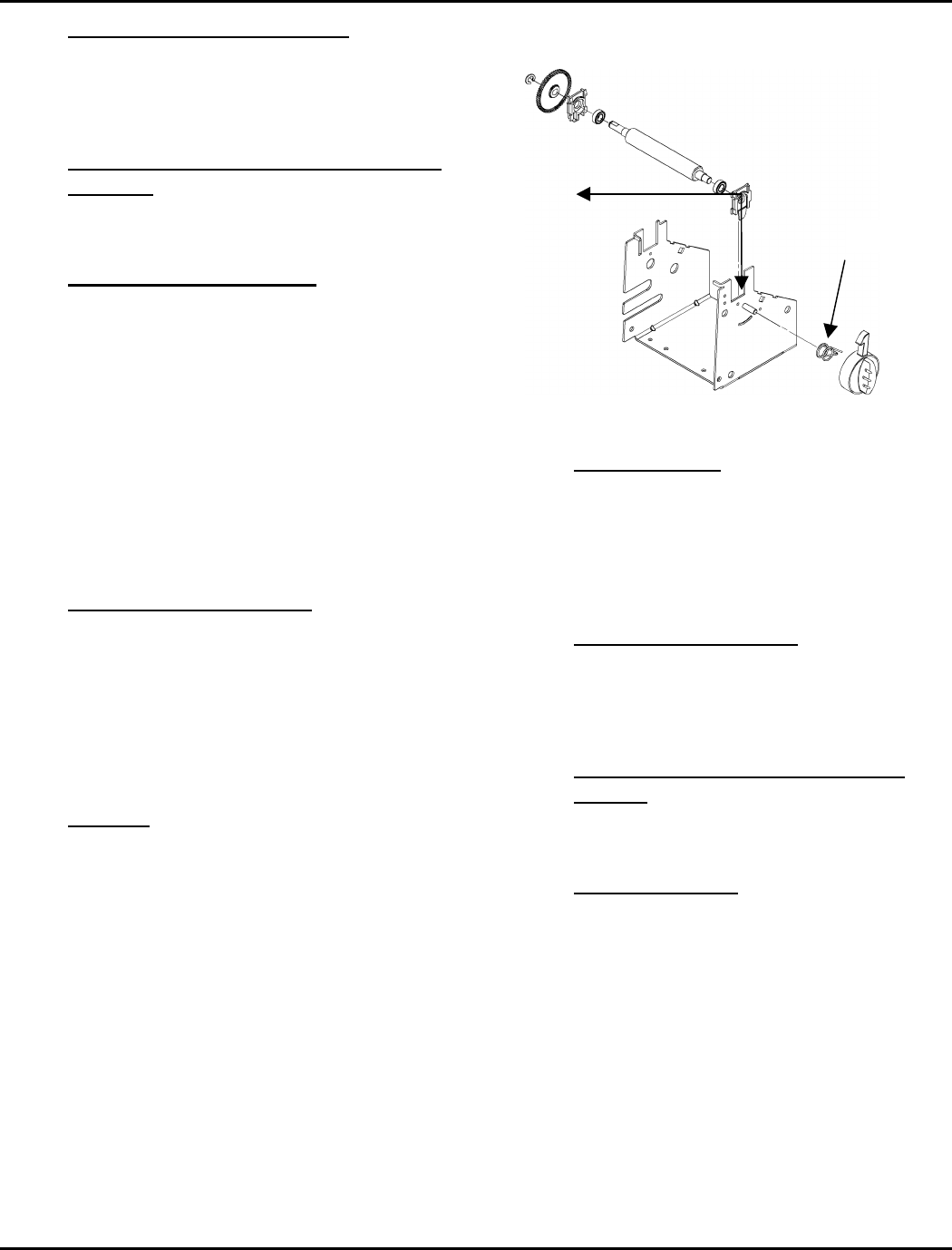

FEED ASSEMBLY

The feed module components are mounted on a metal

frame positioned beneath the Print module and

fastened to the printer base. Components of the feed

module are:

Figure 2- 2. Feed Assembly

Platen Module

The platen rollers are on top of the feed module frame

just beneath the printhead. It is held in place by two

bearing blocks latched on the frame sides. The inner

side of the platen roller shaft extends through the

inside wall of the feed module where a drive gear is

attached.

24VDC Stepper Motor

The stepper motor is located behind the mid-frame of

the printer. Its drive shaft and gear extends through to

the space between the printer mid-frame and the feed

module frame.

Lower Supply Guide and Bi-Cell

Sensor

See Chapter 8, “Supply Sensing Systems” for more

information.

Printhead Latch

The printhead latch is spring loaded and mounted on

the outside of the feed module frame; within the latch

fascia. It locks the printhead in position.

Functional Description

The feed module transports supply through the printer

and across the printhead. It also maintaining proper

alignment, tension, and speed. This is accomplished

by sensing the stock position while securing the

printhead down onto the platen roller. Major functions

are supply feeding and supply sensing. See Chapter

8, “Supply Sensing Systems” for more information.

Bearing

Blocks

Spring

Latch