Tests and Adjustments Confidential 9820/9830/9835 Service Manual

July 1998 TC9830SM Rev. B 7/98 Confidential 25

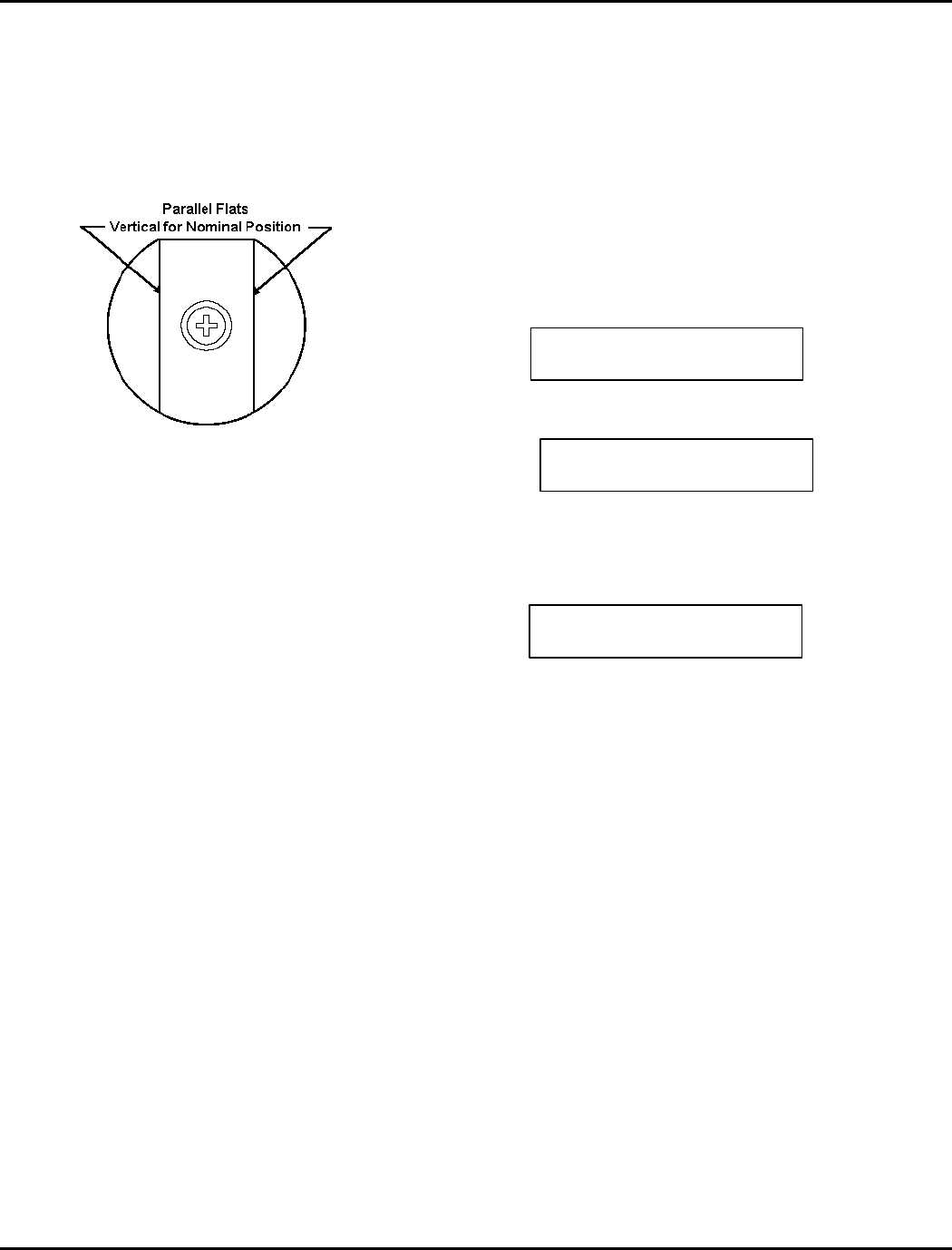

1. Ensure printer is in Normal Mode with the

printhead Wide/Narrow detents set to Wide.

2. Loosen locking screw and set eccentric at the

nominal position (vertical for take-up roller,

horizontal for supply roller). See Figure 5-3.

3. Tighten both locking screws.

Figure 5- 3. Eccentric And Locking Screw

4. Press Feed several times until the supply roller

serrations are visible across the ribbon width.

5. Turn supply eccentric clockwise until serrations

are the same across the ribbon width.

6. Hold eccentric and tighten locking screw to secure

the adjustment.

7. Press Feed several times until the serrations of

the take-up roller are visible across the ribbon

width.

8. Turn take-up eccentric clockwise until serrations

are the same across ribbon width.

9. Hold eccentric and tighten locking screw.

10. Press Feed and Pause (to get test labels) several

times and watch for ribbon wrinkle.

11. If wrinkles occur, re-check step 8 to ensure take-

up roller is properly adjusted. If wrinkles occur,

repeat adjustment.

12. Re-check that printhead Wide/Narrow detents are

set to Wide (button locked down).

13. Press Feed several times and observe the

smoothness of the ribbon as it enters the

printhead platen roller area. Readjust the supply

roller eccentric as required.

14. If wrinkles occur, loosen the take-up eccentric

screw with the printer running, and rotate the

eccentric to eliminate wrinkle.

15. Hold eccentric and tighten the screw.

CHECKING SUPPLY QUALITY

The printer continuously stores data from the most

recent 16 supplies printed. This checks the reflectivity

of the sensor marks on the supply. Before you check

your supply quality, print a batch of supplies or test

labels. Use Sendfile version 2.19 to check your

supply quality. This test can also be performed using

the optional 917 Keypad.

To check your supply quality from the optional

keypad:

1. From the Diagnostics menu, press L or R until

you see

2. Press E. You will be at the User Diagnostics

menu. Press L or R until you see

3. Press E. If you have not printed any labels,

the message “No data! Press Enter” appears.

If you have printed labels since turning on the printer,

you will see

The Len listing is the length of the loaded supply in

dots. The Min listing should be greater than the Max

listing when

• white is under the sensor.

• a die cut label gap is under the sensor.

The Max listing should be greater than the Min listing

when

• black is under the sensor.

• the solid black area of a die cut label is under

the sensor.

The OK listing tells whether the sense mark on the

supply passed a detection test. Press R to see the

other readings.

If you are not using a Version 5.2 sensing system and

you try to check the supply quality, the message “HW

not supported” appears.

DIAGNOSTICS

l User Diag. r

USER DIAG

Supply Quality r

Len Min Max OK

l 1568 034 124 Y r