LC2H

105

Cautions for use

1. Non-voltage input type

For both panel mounting and PC

board mounting types

1) Never apply voltage to the non-voltage

input type. This will damage the internal

elements. Also, since there is a possibility

of erroneous operation, do not connect in

parallel the inputs of a non-voltage input

type and another counter from a single

input signal.

2) Since the current flow is very small

from the count input and reset input

terminals (1 and 3 on the panel

mounting type and terminals e to t and

S to F on the PC board mounting type)

please use relays and switches with high

contact reliability.

3) When inputting with an open collector

of a transistor, use a transistor for small

signals in which ICBO is 1 µA or less and

always input with no voltage.

4) When wiring, try to keep all the input

lines to the count and reset inputs as

short as possible and avoid running them

together with high voltage and power

transmission lines or in a power conduit.

Also, malfunctions might occur if the

floating capacitance of these wires

exceeds 500 pF (10 m 32.808 ft. for

parallel wires of 2 mm

2

). When using 2

kHz mode, use with a wiring floating

capacitance of 120 pF (3 m 9.843 ft. for

parallel wires of 2 mm

2

). In particular,

when using shielded wiring, be careful of

the capacitance between wires.

PC board mounting type

1) For external power supply use

manganese dioxide or lithium batteries

(CR type: 3V).

2) Always reset after external power is

applied and confirm that the display

reads “0”.

3) Make the wiring from the battery to the

counter unit as short as absolutely

possible. Also, be careful of polarity.

4) Calculate battery life with the following

formula.

t = A/I

t: battery life [h]

I: LC2H current consumption [mA]

A: battery capacity until minimum

operation voltage is reached [mAh]

5) Hand solder to the lead terminal. Do

not dip solder. With the tip of the

soldering iron at 300°C 572°F perform

soldering within 3 seconds (for 30 to 60

W soldering iron).

2. Voltage input type

1) Be aware that applying more than 30 V

DC to count input terminals 1 and 2,

and reset input terminals 3 and 4 will

cause damage to the internal elements.

2) For external resetting use H level

(application of 4.5 to 30 V DC) between

reset terminals 3 and 4 of the rear

terminals. In this case, connect + to

terminal 3 and – to terminal 4. This is

the valid polarity; therefore, the counter

will not work if reversed.

3) When wiring, try to keep all the input

lines to the count and reset inputs as

short as possible and avoid running them

together with high voltage and power

transmission lines or in a power conduit.

Also, malfunctions might occur if the

floating capacitance of these wires

exceeds 500 pF (10 m 32.808 ft. for

parallel wires of 2 mm

2

).

3. Free voltage input type

1) Use count input terminals 1 and 2 for

free voltage input and reset terminals 3

and 4 for non-voltage input.

2) Be aware that the application of

voltage that exceeds the voltage range of

the H level to the count input terminal,

and the application of voltage to the reset

input terminal, can cause damage to the

internal elements.

3) Since the current flow is very small

from reset input terminal 3, please use

relays and switches with high contact

reliability.

4) When inputting a reset with an open

collector of a transistor, use a transistor

for small signals in which ICBO is 1 µA or

less and always input with no voltage.

5) To reset externally, short reset input

terminals 3 and 4 on the rear.

6) Input uses a high impedance circuit;

therefore, erroneous operation may occur

if the influence of induction voltage is

present. If you plan to use wiring for the

input signal that is 10 m or longer (wire

capacitance 120 pF/m at normal

temperature), we recommend the use of

a CR filter or the connection of a bleeder

resistor.

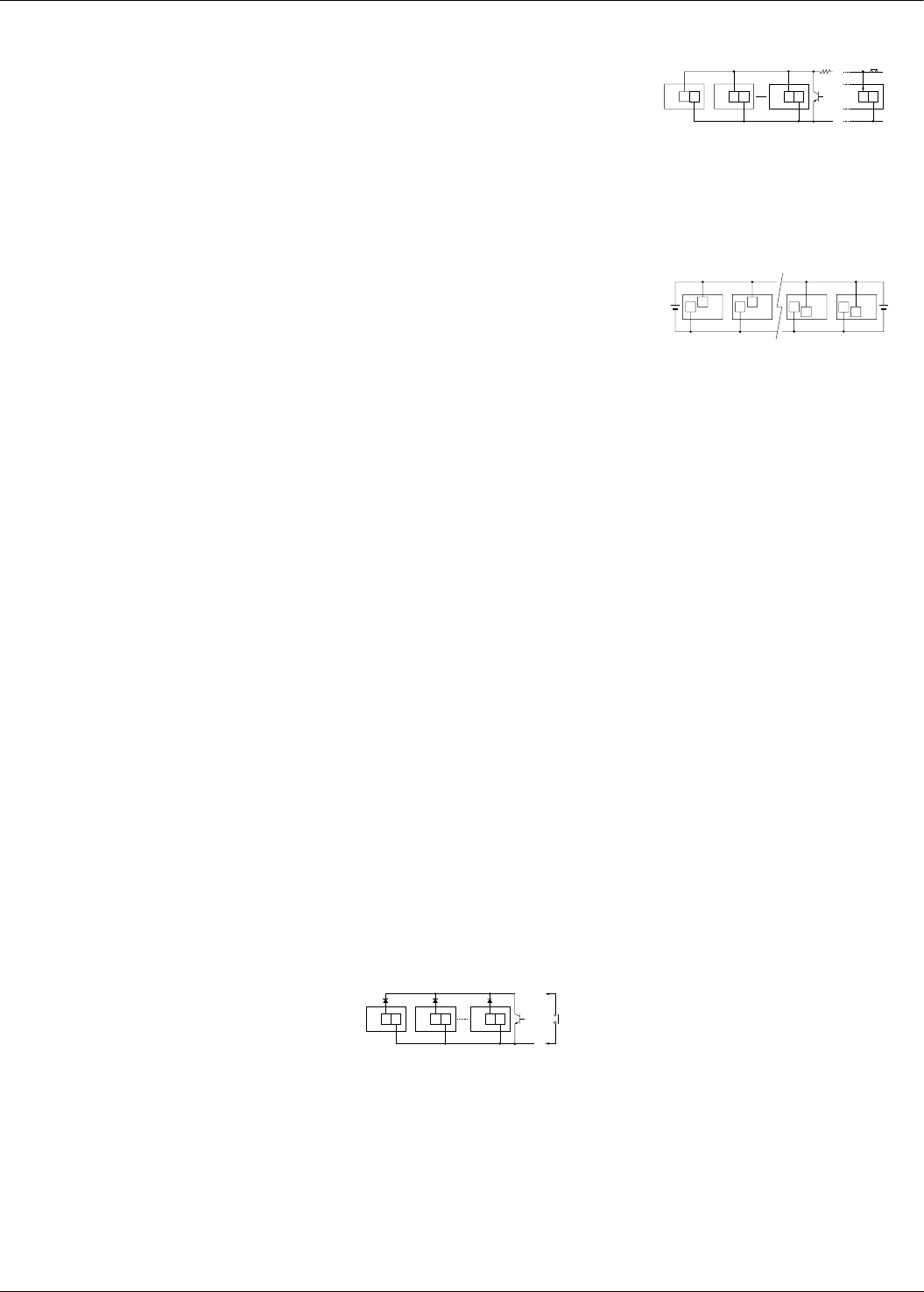

4. How to reset multiple panel

mounting type counters all at once

(input is the same for count)

Non-voltage input type

Notes) 1. Use the following as a guide for choosing

transistors used for input (Tr).

Leakage current < 1 µA

2. Use as small a diode (D) as possible in the

forward voltage so that the voltage between

terminals 3 and 4 during reset input meets

the standard value (0.5 V).

( At IF = 20 µA, forward voltage 0.1 and

higher.)

Voltage input type

Note) Make sure that H (reset ON) level is at least 4.5

V.

5. Backlight luminance

To prevent varying luminance among

backlights when using multiple Backlight

types, please use the same backlight

power supply.

6. Environment for use

1) Ambient conditions

• Overvoltage category II, pollution level 2

• Indoor use

• Acceptable temperature and humidity

range: –10 to +55°C, 35 to 85%RH (with

no condensation at 20°C)

• Under 2000 m elevation

2) Use the main unit in a location that

matches the following conditions.

• There is minimal dust and no corrosive

gas.

• There is no combustible or explosive

gas.

• There is no mechanical vibration or

impacts.

• There is no exposure to direct sunlight.

• Located away from large-volume

electromagnetic switches and power

lines with large electrical currents.

3) Connect a breaker that conforms to

EN60947-1 or EN60947-3 to the voltage

input section.

4) Applied voltage should be protected

with an overcurrent protection device

(example: T 1A, 250 V AC time lag fuse)

that conforms to the EN/IEC standards.

(Free voltage input type)

3

or

D

Tr

4 3 4 3 4

D D

3

or

+V

+V

R

Tr

4 3 4 3 4 3 4

2

2

5

2

Green Red

5

6

2

6

24V DC 24V DC

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net