97

Appendix C

Repumping the Vacuum

Introduction

Fiberoptic taper CCD cameras are shipped with a vacuum level below 10

-5

Torr to assure

proper cooling performance and to prevent condensation from collecting on the CCD. In

time, the vacuum level could deteriorate to where achieving temperature lock will no

longer be possible. If this happens, it will be necessary to restore the vacuum.

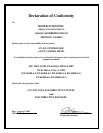

A ¼ Vacuum Pumping fitting (Figure 56) is supplied with the camera but is not factory

installed. The access port, located at the top of the camera, is capped. The cap can easily

be removed, allowing the vacuum pumping fitting to be installed.

Figure 56. Vacuum Pumping Fitting

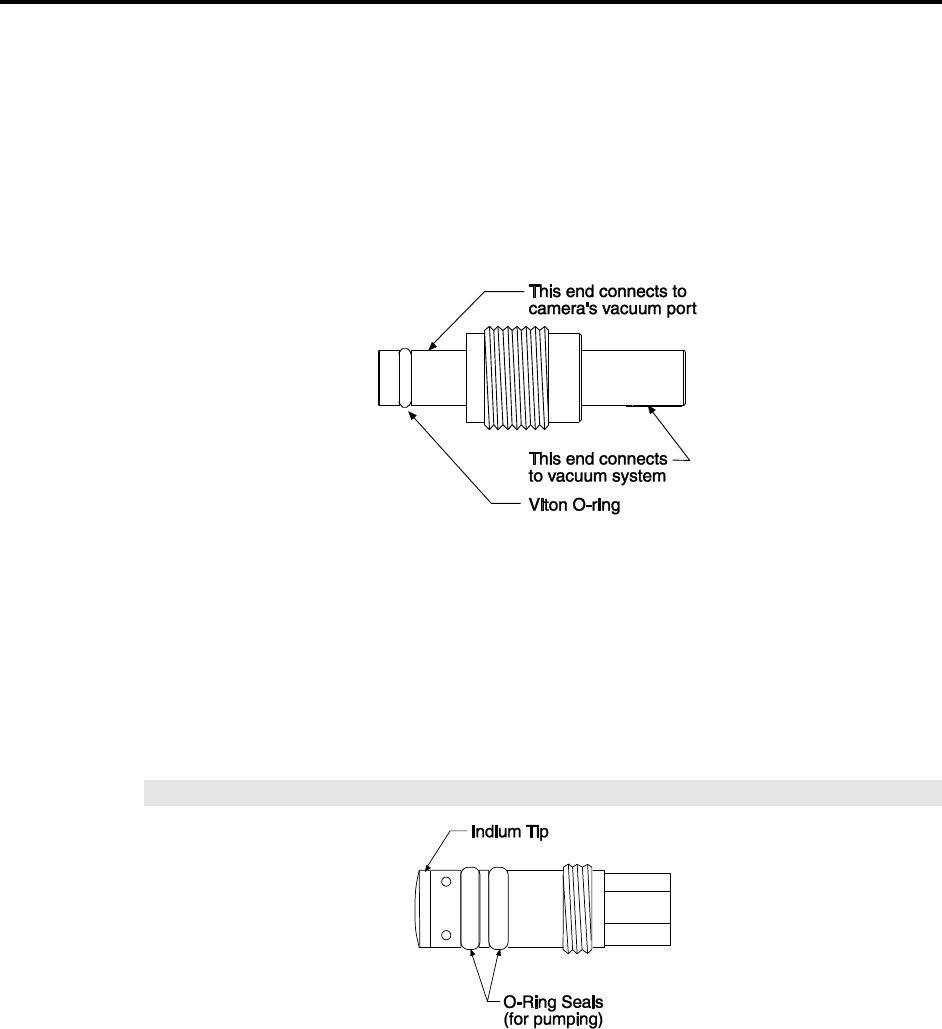

A special Indium-tipped Vacuum Seal (Figure 57) is installed in the side of the camera

(see Figure 15 on page 39). At installation, the Vacuum Seal’s Indium tip is crushed to

provide a metal-to-metal seal in the vacuum chamber. The number of times this can be

done before a new Vacuum Seal is required is limited. Typically, an Indium tip can be

crushed up to ten times before the Vacuum Seal must be replaced to assure a good

vacuum seal. Because the tip is crushed only once at the factory, it can be successfully

used again numerous times in the field. With repeated repumpings, however, it will

eventually be necessary to replace the Indium-tipped Vacuum Seal (PI #2550-0352).

Note: The required seating torque for successful vacuum sealing is 28 in. lb. (3.2 Nm).

Figure 57. Indium-tipped Vacuum Valve