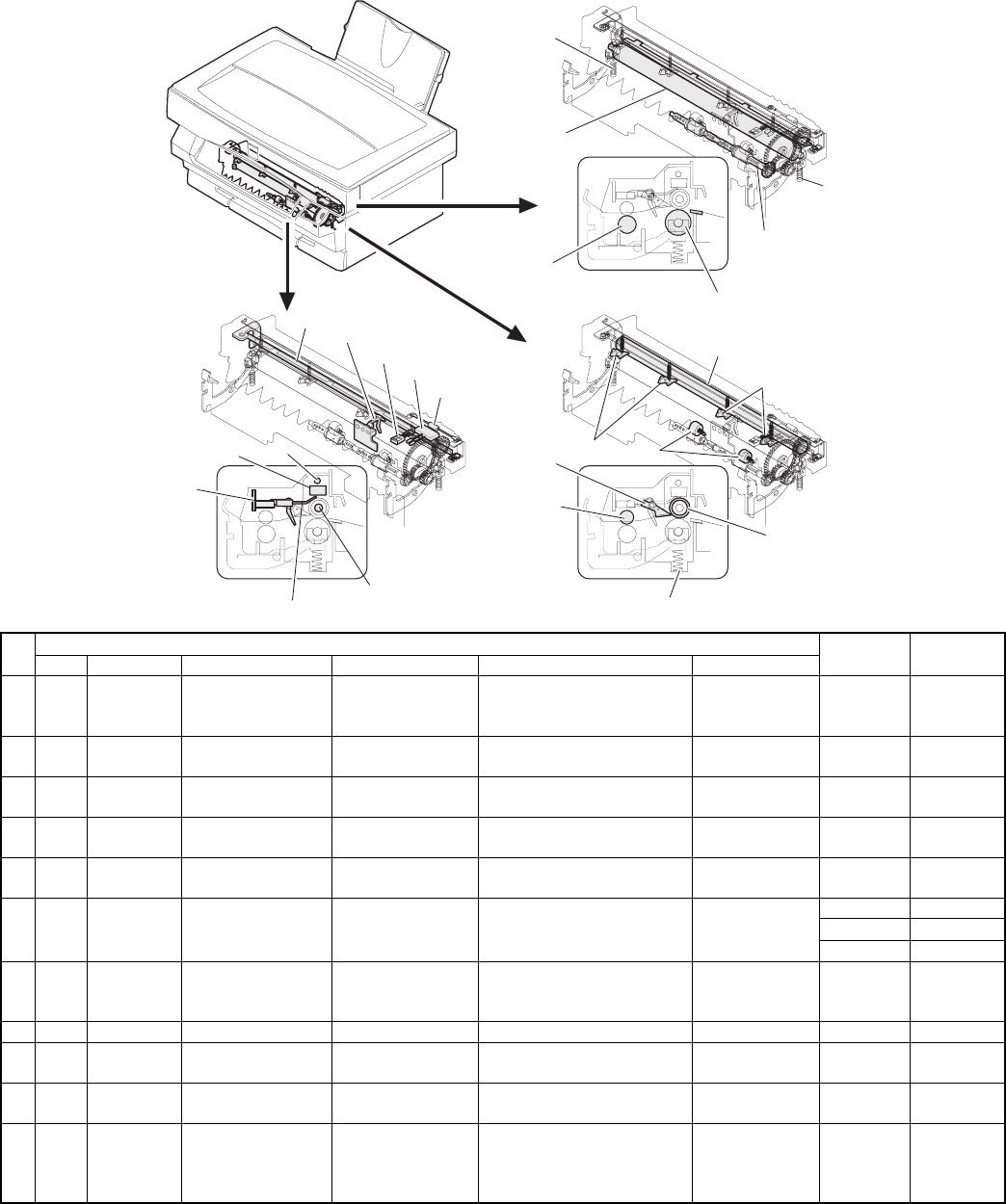

E. Fusing/paper exit section

(1) Outline

Toner attracted to the paper in the transfer section is fused by heat

and pressure of the heat roller. The heat roller is of thin aluminum

roller which is high heat conductivity, minimizing the warm up time.

The heat roller surface temperature is detected by the fusing

temperature sensor to maintain the fusing temperature at a constant

level (160/155 ˚C).

(2) Major parts

No.

Parts

MODEL Note

Code Signal name Name Type Function/operation Active condition

1 Heat roller Heats toner on the paper and

fuses onto the paper.

LOW (0V) when

paper is

detected.

2 POUT POUT IN Paper exit detector Photo transmission

sensor

Detects paper exit.

3 RTH IN Fusing temperature

sensor

Thermistor Detects the heat roller

surface temperature.

4 Temperature fuse 1

(Fusing section)

Mold Assures safety in overheating.

5 Temperature fuse 2

(Fusing section)

Mold Assures safety in overheating.

6 HL Heater lamp Halogen lamp Heats the heat roller. 100V series 10V 500W

120V series 120V 500W

200V series 230V 500W

7 Pressure roller Applies a pressure to the

heat roller and paper to

improve fusing efficiency.

8 Paper exit roller Discharges paper after fusing.

9 Separation pawl Separates paper from the

fusing roller mechanically.

10 Paper exit roller Discharges paper outside the

machine after fusing.

11 Pressure spring Applies a pressure to the

heat roller, paper, and

pressure roller to improve

transfer efficiency.

7)

8)

11)

9)

1)

9)

10)

5)

4)

3)

2) POUT

6)

7)

8)

11)

1)

11)

10)

9)

6)

3)

2) POUT

4) 5)

1 – 25