33

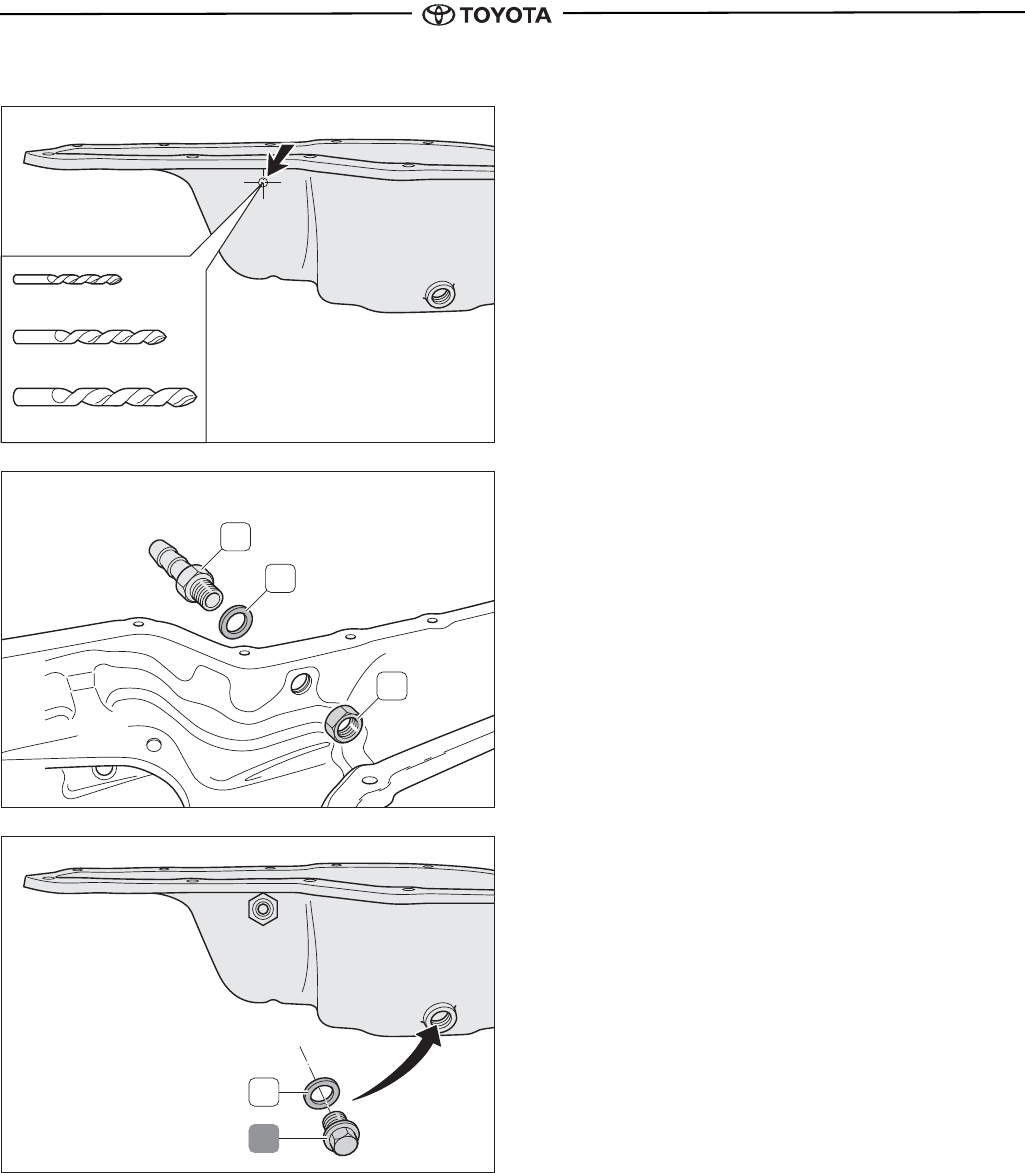

5. Oil-sump preparation

1. INSTALL OIL RETURN ADAPTER.

(a) Mark the position of the oil return hose adapter.

(b) Punch-mark the drilling position.(spot-weld position)

(c) Pre-drill a 4 mm hole.

(d) Pre-drill to 6.5 mm

(e) Drill the hole out to 12mm.

(f) Remove burrs.

(g) Install the oil return adapter with the nut and copper

gasket and Loctite No.270

K: Adapter (14-1)

K: Nut (14-2)

K: Copper gasket (14-7)

Torque: 45 Nm

(h) Install the oil drain plug with a new gasket.

K: Gasket (14-7)

R: Oil drain plug

Torque: 37 Nm

2. CLEANING.

(a) Remove all liquid gasket remains from the contact

surface.

(b) Clean the oil-sump in a parts wash system to ensure

all gasket and drilling particles are removed.

NOTICE: Check if the gasket contact surface is

straight and clear due to removal

activities.

Ø 4 mm

Ø 6,5 mm

Ø 12 mm

K

K

K

K

R