4-24 DocuTech 128/155/180 HighLight Color Operator Guide

Problem Solving

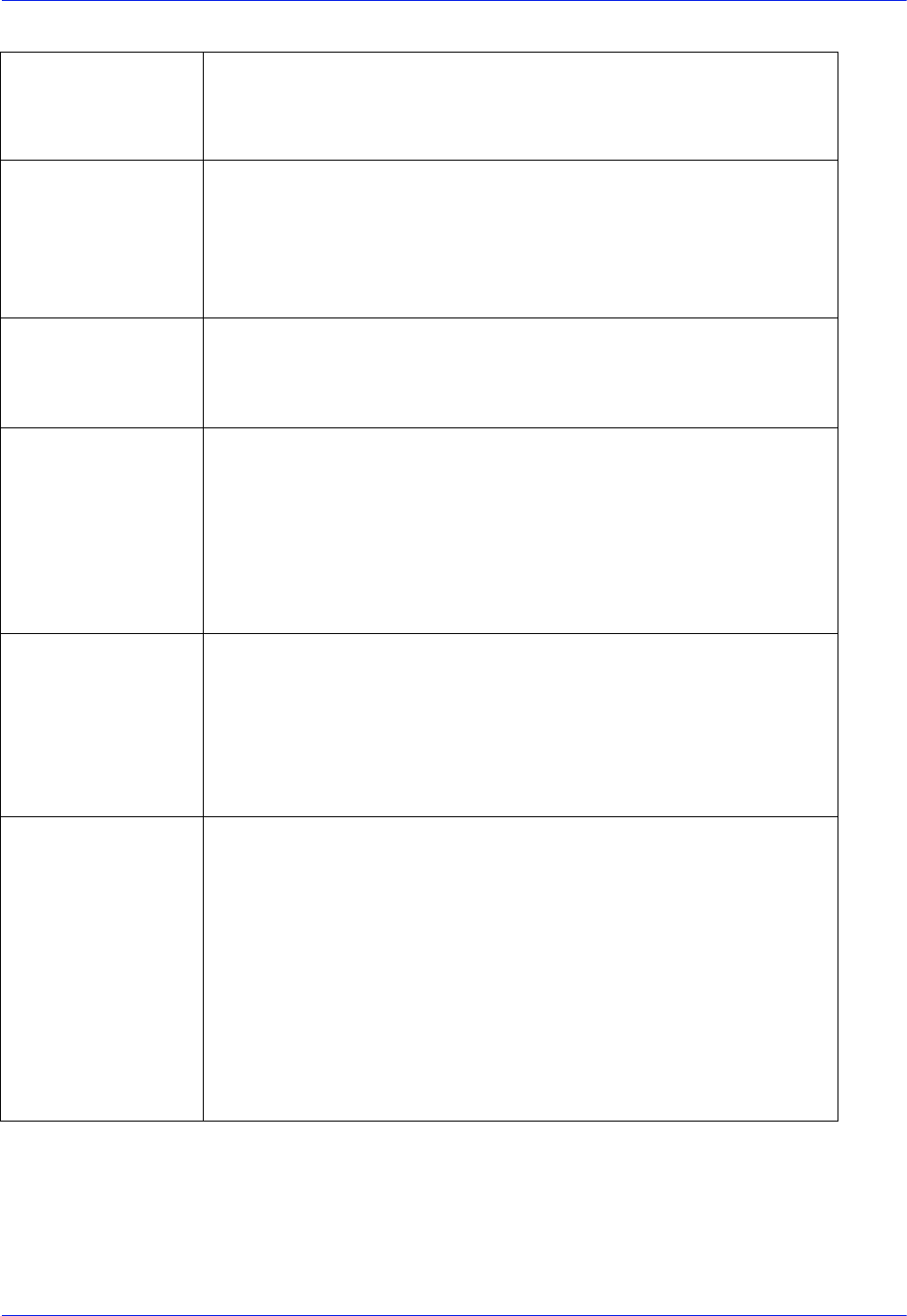

Binder tape not

positioned correctly

on the top edge of

the output prints

Adjust the binder tape registration using the procedure, "Adjusting

the binder tape registration," in this guide.

Binder tape is too

long or too short on

the bottom edge of

the output prints

Adjust the binder tape length using the procedure entitled "Adjusting

the binder tape registration" in the "Routine maintenance" chapter.

If an adjustment is made to the binder tape length during a job, it will

not take effect until the next job is printed. If it is necessary to adjust

the binder tape length during a job, adjust it using the procedures in

the on-line help.

Loose binder tape

along the spine of

the completed

bound book

This is a symptom of excessive moisture in the tape. Replace the

tape reel with a new reel using the procedure, "Replacing the binder

tape reel," in the "Routine maintenance" chapter.

Refer to the binder tape storage guidelines in this guide.

Repeated tape

feeding problems,

such as binder tape

not unwinding from

the reel

If the binder tape is sticking together, or if there are cosmetic defects

in the bound book, replace the tape reel with a new reel using the

procedure, "Replacing the binder tape reel," in the "Routine

maintenance" chapter.

Refer to the binder tape storage information in this guide.

Refer to the binder cleaning information in this guide.

Refer to information on calling the Customer Support Center in this

guide.

Stitcher fault codes

displayed in the fault

frame

Fault Code P12-218

Fault Code P12-219

Select the [Finishing] button on the Printer Manager window.

Deselect [Stitcher] on the Finishing window and refer to the

procedure, "Calling for assistance," in this guide.

Stitcher A problems. Perform the procedure, "Clearing a stitcher

spool A fault," in this guide.

Stitcher B problems. Refer to information on calling the Customer

Support Center in this guide.

Poor stitch quality or

short stitches

Reliable stitching can be expected with up to 65 sheets of substance

20 (75 g/m2) or 0.28 inch (7 mm) thick sets. Less reliable stitching

can be expected with over 70 sheets of substance 20 (75 g/m2).

Running intermixed stock heavier than substance 20 (75 g/m2) will

reduce the capacity of the stitcher.

To avoid short clinches, use the stitch override only when using a

lightweight paper. Stitch override allows the system to run beyond

the stitching limit. The system will shut down at 125 sheets.

Reduce the stock weight to enable the stitching of more sheets per

set.

Refer to the satisfaction guides in the "Technical information"

chapter.

Table 4-3. Resolving a finisher problem