Temperature Management OmniSwitch 6600 Series Chassis and Hardware Components

page 2-48 OmniSwitch 6600 Series Hardware Users Guide April 2004

Blank Cover Panels

Blank cover panels are provided with your switch and are used to cover empty uplink and stacking module

slots, as well as empty back up power supply bays (if applicable). These cover panels play an important

role in chassis airflow and temperature management. They also protect the switch’s processor board and

other sensitive internal switch components from physical damage by closing off a chassis that is not fully

populated.

If your switch is not fully populated with submodules and a redundant power supply, and blank cover

panels are not installed over empty slot locations, airflow is adversely affected.

When blank cover panels are missing, air does not take the direct route from the air intake vent, through

the chassis, and then out through the fan exhaust vents. Instead, a portion of the airflow is allowed to be

drawn in through the front and rear of the chassis. As a result, normal airflow is disrupted and an extra task

is placed on the fans to cool the chassis.

Cover panels also provide protection for module processor boards and other sensitive internal switch

components by closing off a chassis that is not fully populated.

Because they regulate airflow and help protect internal chassis components, blank cover panels should

remain installed over empty module slots and power supply bays at all times.

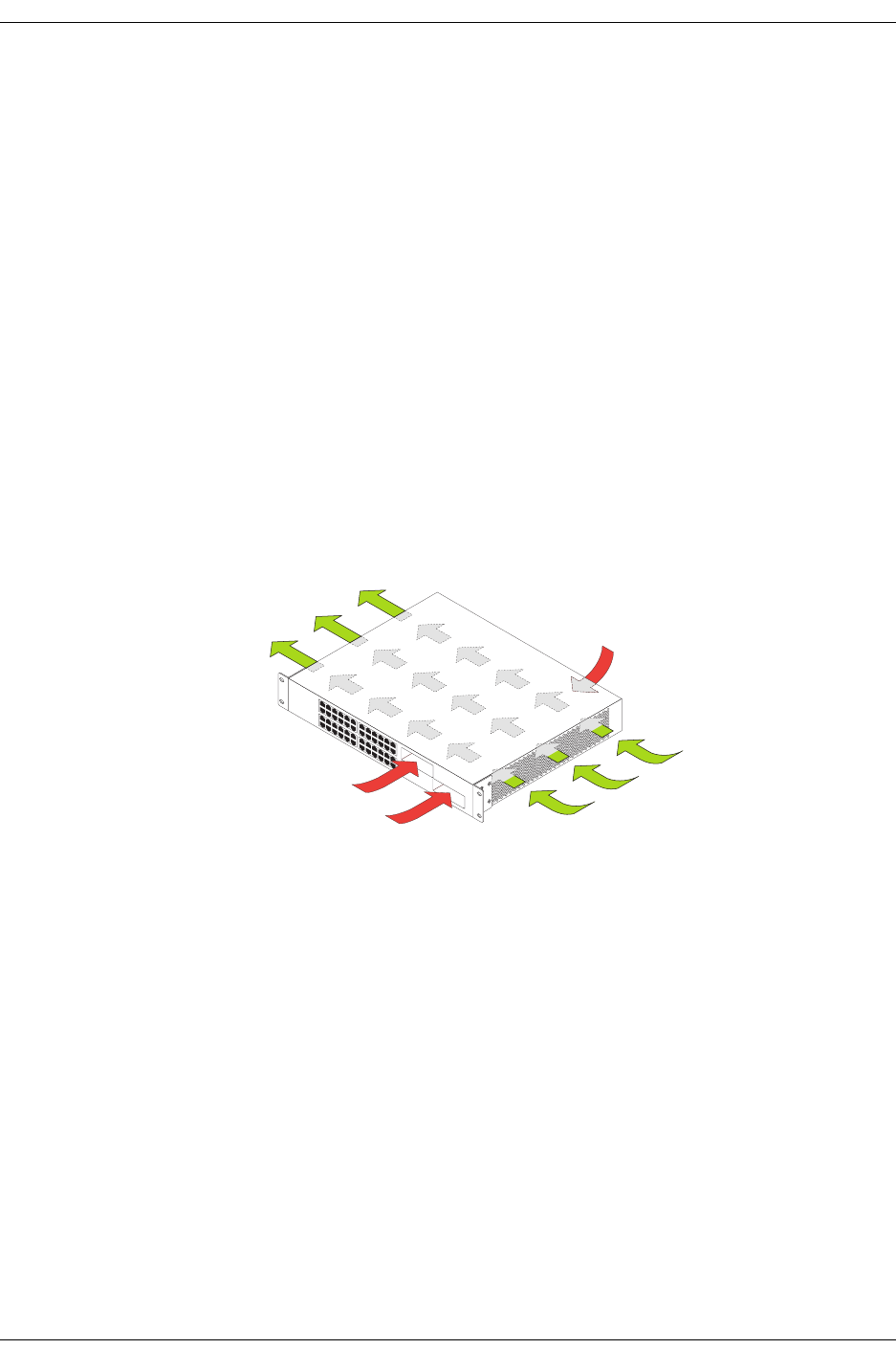

Effects of Missing Blank Panels on Chassis Airflow

Missing Cover Panels.

Missing cover panels affect

airflow by allowing air to be

drawn in through the front

submodule bays or rear

redundant power supply bay.

As a result, the direct route

from the air intake vent to the

fan exhaust vents is dis-

rupted.

For optimal airflow and

chassis component protec-

tion, always install blank

cover panels over empty

slots and power supply bays.

Air Intake Vent

Air leakage due to

missing submodule

cover panels

Air leakage due to

missing redundant

power supply panel