MTEK6000 SERIES USER'S MANUAL

January 2002 2-7

TRANSDUCERS IN THE MTEK6000

The MTEK6000 uses a precision strain gauge

pressure transducer mounted inside the unit,

combining maximum accuracy with low

power consumption. To sense gas

temperature, the MTEK6000 employs a

highly linear and stable device, a platinum

resistive temperature detector (RTD). Case

temperature sensing is accomplished with an

on-board precision reference integrated

circuit (IC).

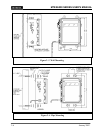

CONNECTING THE PRESSURE

TUBING

WARNING

You must DEPRESSURIZE THE METER

and its associated piping before you make

pressure piping connections. FAILURE to

do so may result in EXPLOSION and FIRE,

causing SERIOUS PERSONAL INJURY

and PROPERTY DAMAGE.

Do NOT attempt to connect any piping or

fittings to a meter or pipe under pressure.

Do NOT SMOKE while connecting gas or

test pressure to the meter.

Note

Federal Standard 192.02 requires a shut-off

valve between the pressure source and the

instrument. A needle valve is supplied with

the optional pressure piping kit for this

purpose. Its rating is 1,500 PSIG MAOP.

As a minimum requirement, connect the

pressure tubing as shown in Fig. 2-7. An

optional pressure tubing connection kit (part #

2019-0009B-001) can be shipped with each

instrument. Fig. 2-8 is the recommended

pressure installation for ease of operation.

Additional piping and valve are required for

the installation and are not supplied. Use

Teflon tape or pipe seal compound on all

threaded connections. The tubing supplied in

the kit may be longer than you need for your

installation. You can cut or coil the tubing,

but do not make any sharp bends in it

(minimum radius is 3/4"). Tighten all the

connections and perform a leak test once the

meter and instrument are pressurized.

Figure 2- 5 Pressure Connections