F - 160 Operation and Maintenance Manual

© GBC Pro - Tech August 1999Page 5 - 10

Operations

d) Once the roll of laminate is on the unwind shaft,

swing the unwind shaft back into the saddle.

Make sure the roll of laminate is properly

on the unwind shaft. The adhesive, when

exposed should be facing away from the

rollers. This will prevent hours of roll

cleaning.

CAUTION

e) Push the clevis pin back down to secure the

unwind shaft its saddle.

f) Now you must center the roll of laminate on the

unwind shaft. Refer to Figure 5.3.3 for

measurements. For centering measurements,

refer to Figure 5.5.4.

g) For the lower unwind shaft, repeat steps “b”

through “f” again.

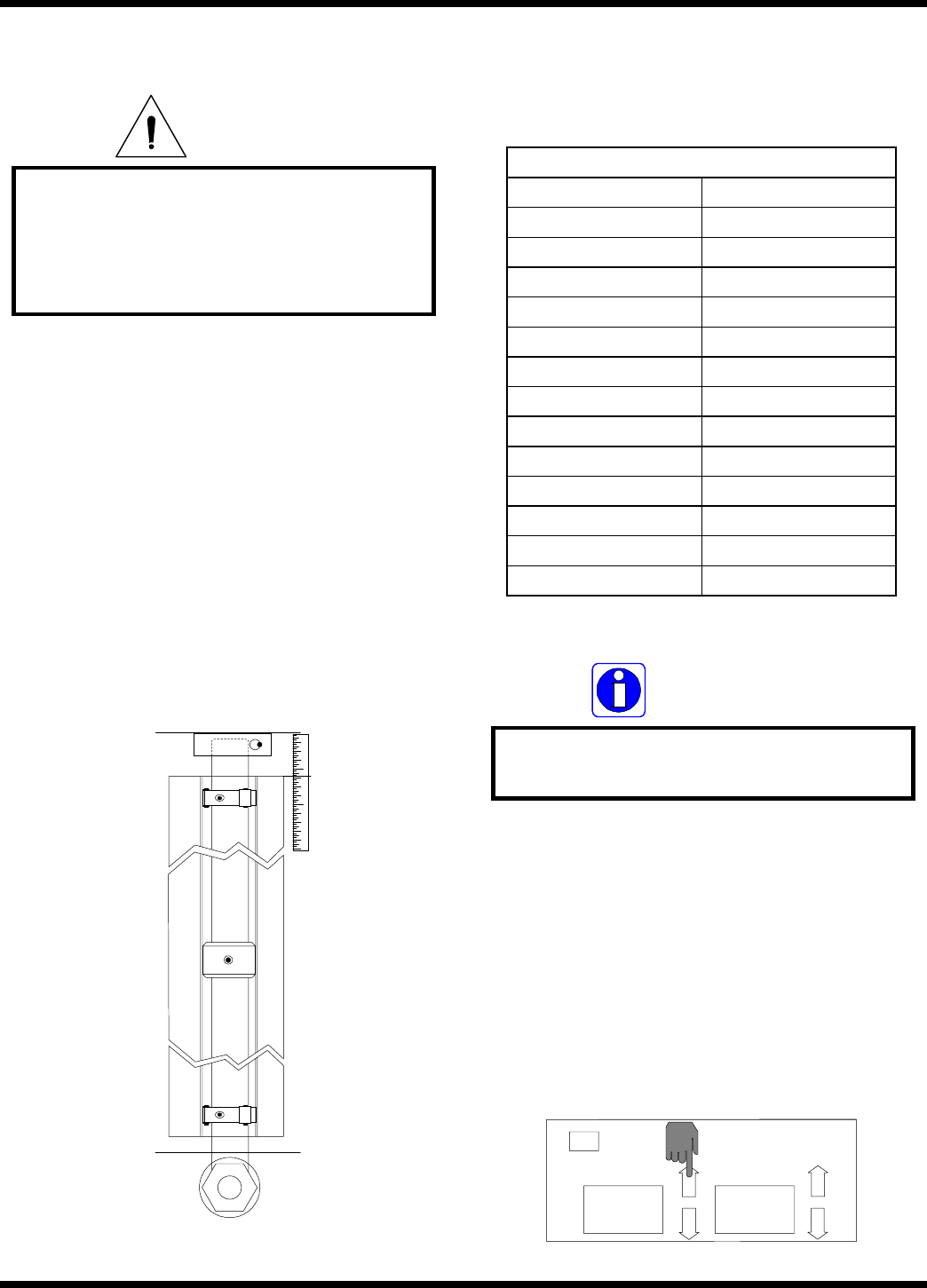

Figure 5.3.3 Centering the roll

Measure from

the side frame

to the edge of

the roll of

laminate.

Make sure

the laminate

is flush with

the core.

h) Close the rear safety shield when finished.

Figure 5.3.4 Measurement chart

Most common film widths

12 " 28 "

24 " 22 "

31 " 18.5 "

37 " 15.5 "

41 "

15 "

47 "

13.5 "

49 "

10.5 "

51 "

9.5 "

55 "

8.5 "

58 "

6.5 "

60 "

5 "

62 "

4 "

38 "

3 "

Film width Measurement

INFORMATION

For the lower unwind shaft, add 1/4 in. to

the measurement.

5.3.5 Heating

Perform the following steps.if the application

requires heat. Allow the rolls to heat up while rotating

for even heat disbursement.

a) Press TOP TEMP. s to set your upper roller

temperature.

TOP TEMP.

BOT. TEMP

SLEEP

68

68