2 – 21

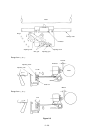

(2) Operation of printhead (See Figure 2-3.)

(a) When the printhead is idle, the armature is attracted by a permanent magnet and

the spring fixing the armature is compressed. The print wires fixed to each armature

are thus concealed under the wire guide.

(b) When a signal for a character to be printed is detected, a current flows through the

coil. When the coil is activated, the magnetic flux (caused by the permanent magnet

between the armature and the core) is canceled to eliminate the attraction force. The

armature is driven in the direction of the platen by the force of the armature spring.

The print wire fixed to the armature protrudes from the tip of the wire guide, strikes

the paper through the ribbon and prints a dot on the paper.

(c) After the character has been printed, the armature is magnetically attracted again

and the print wires are again concealed under the wire guide.

A thermistor in the printhead prevents burning caused by over-heating of the coil

during extended continuous bi-directional printing. When the temperature of the coil

exceeds a pre-determined limit (about 119°C) the control circuit detects a thermistor

signal. Printing will then be intermittent or stop completely until the coil temperature

falls below the limit value.