11

8. Water

resistance

Select the sealed-type for exposure to water. In the case of water exposure in severe conditions or

immersion, please verify water resistance of the relay or contact us. Even for sealed-type relays, its

terminals are not waterproof, so please avoid a failure such as terminal corrosion.

Note that moisture adhered on relay in a due condensation or a high humidity condition freezes when

the temperature is lower than 0°C. This may cause problems such as sticking of movable parts or

operational time lags, or poor contact conduction. Therefore, please test them in actual use

environment.

9. Freezing

Note that if a relay is connected or installed with a high heat-capacity such as bas bar, connector,

harness, and PCB, heat removal phenomenon will accelerate cooling of the relay inside and promote

freezing. So, please verify in actual installation condition.

12. Usage

ambient

condition

10. Low

temperature,

low humidity

The plastic becomes brittle if the relay is exposed to a low temperature, low humidity environment for

long periods of time.

Please consider the vibration at installation area to avoid loosely-contact.

Also, note that even a microscopic vibration may cause contact failure at the contact area of relay

terminal and connector.

Decrease of fitting performance of connector may cause abnormal heat at connector contact area

depending on use temperature and applying heat. Sufficient margin of safety must be provided in

selection of a connector.

13.Installation 1. Connector

installation

Please select the proper material of connector and surface treatment to avoid corrosion at the contact

area of relay terminal and connector and increase of resistance at connecting area which may be

caused depending on ambient environment.

14. PC board

design

1. PC board

design

consideration

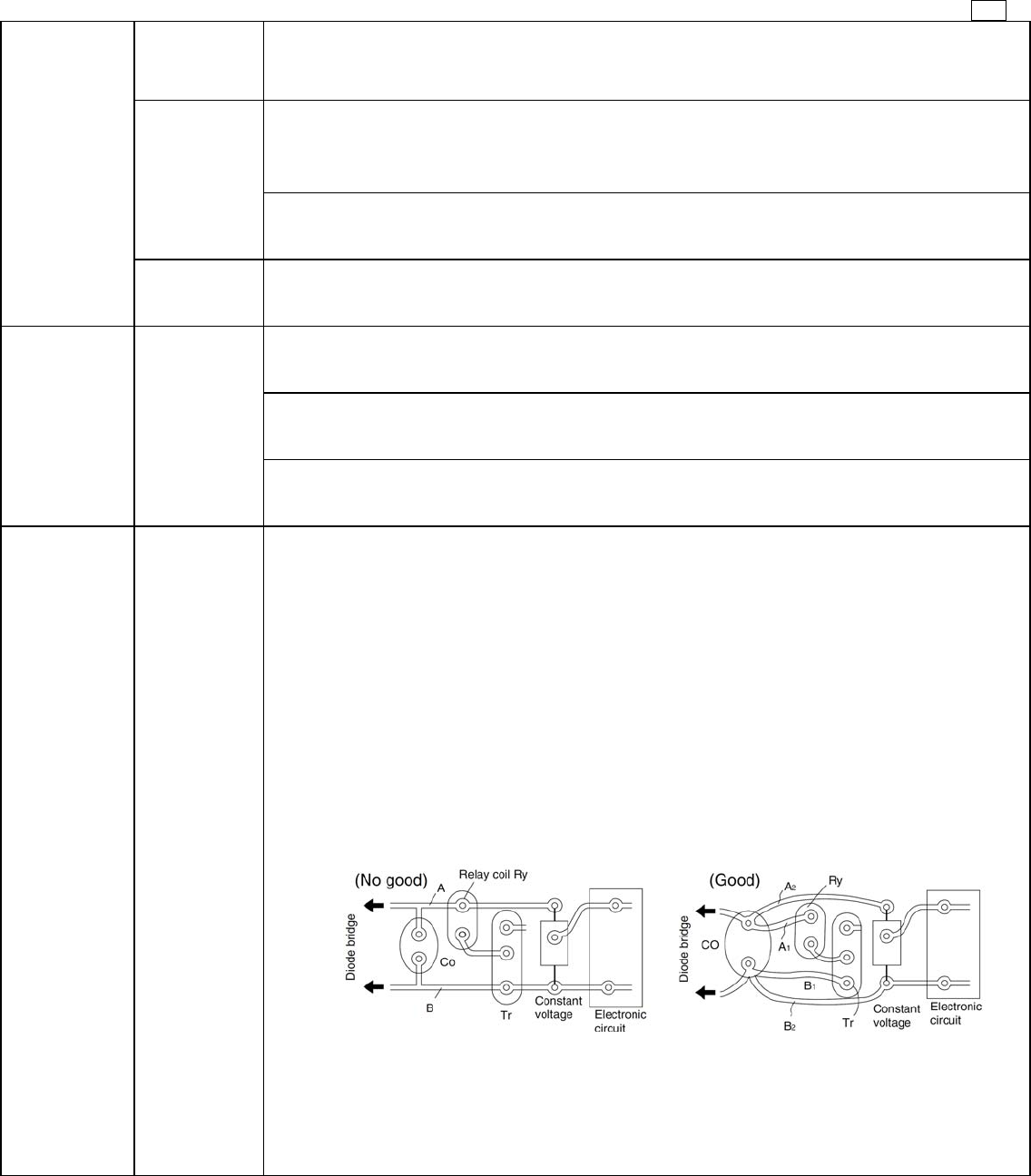

1. Cautions regarding Pattern Layout for Relays

Since relays affect electronic circuits by generating noise, the following points should be noted.

• Keep relays away from semiconductor devices.

• Design the pattern traces with the shortest length.

• Place the surge absorber (diode, etc.) near the relay coil.

• Avoid routing pattern traces susceptible to noise (such as for audio signals) underneath the

relay coil section.

• Avoid through-holes in places which cannot be seen from the top (e.g. at the base of the

relay). Solder flowing up through such a hole may cause damage such as a sealing failure.

• Even for the same circuit, it is necessary to consider the pattern design in order to minimize

the influence of the on/off operations of the relay coil and lamp on other electronic circuits, as

shown in the figure below.

-Relay currents and electronic circuit

currents flow together through A and B.

-Relay coil currents consist only of A1 and B1.

-Electronic circuit currents consist only of A2

and B2. A simple design can change safety o

f

the operation.