2

1. General Contact performance is significantly influenced by voltage and current values applied to the contacts (in

particular, the voltage and current waveforms at the time of application and release), the type of load,

frequency of switching, ambient atmosphere, contact switching speed, and of bounce, which lead the

various other damages such as unsuitable operation contact transfer, welding, abnormal wear, increase

in contact resistance. Therefore, please confirm that in actual use conditions such as actual circuit and

actual load or contact our company.

In the case of switching on and off with inductive loads such as coil, magnet crutch, and solenoid, the arc

at switching can cause a severe damage on contacts and greatly shortening of life. In addition, in the

case of switching at a high frequency, a blue-green corrosion may be developed. So, please contact our

company to use it.

2. Inductive

load

If the current in the inductive load is relatively small, the arc discharge decomposes organic matter

contained in the air and causes black deposits (oxides, carbides) to develop on the contacts. This may

result in contact failure. So, please contact our company to use it.

Large inrush current enhancing contact welding will be impressed. Its current value is greatly affected by

wiring resistance, switching frequency and ambient temperature. The load current characteristics in

actual circuit and actual use condition must be examined and sufficient margin of safety must be

provided in selection of a relay.

3. Lamp load

It is dangerous to use a lamp load whose nominal current is small even a large nominal current has been

tested beforehand.

Please contact us when switching at nominal current with a small lamp load (40W or less), because

continuous ON failure may occur due to locking caused by contact-transfer phenomenon when switching

arc is locally concentrated.

4.Electric-

discharge

lamp load

Its load current tends to cause contact welding easily because its inrush current is larger than that of the

regular lamp load. The load current characteristics in actual circuit and actual use condition must be

examined and sufficient margin of safety must be provided in selection of a relay.

5. LED lamp

load

It is necessary to check the contact reliability because the load current of the LED load is very small.

Please contact us before use.

6. Other lamp

load

Please contact us before use of new structured lamp except for halogen, Electric-discharge lamp, and

LED.

When using of NC contact side of 1C contact for the motor brake, mechanical life might be affected by

the brake current. Therefore, verify in actual use conditions with actual circuit.

7. Motor load

Note that larger inductivity of motor may cause contact damage and transfer even the motor load current

is same.

8. Capacitor

load

Note that its load current tends to cause contact welding and contact transfer easily because its inrush

current is generally large which has a small break current and a short time period to reach an inrush

peak value.

Also, inrush current value is influenced by wiring resistance. Therefore, the inrush current in actual circuit

must be examined and sufficient margin of safety must be provided in selection of a relay.

9. Resistance

load

This load causes relatively-less contact damage since its inrush current is not large. Select a relay based

on the rating control capacity, or contact us.

10. Small

electric

current

load

If the switching current is small (2A or less), contact reliability decreases since the contact surface is not

cleaned by switching arc. So, please contact us for use.

11. Load

polarity

Electrical life may be affected by load polarity (+/-) connecting to relay contacts. So, please verify them in

actual use polarity.

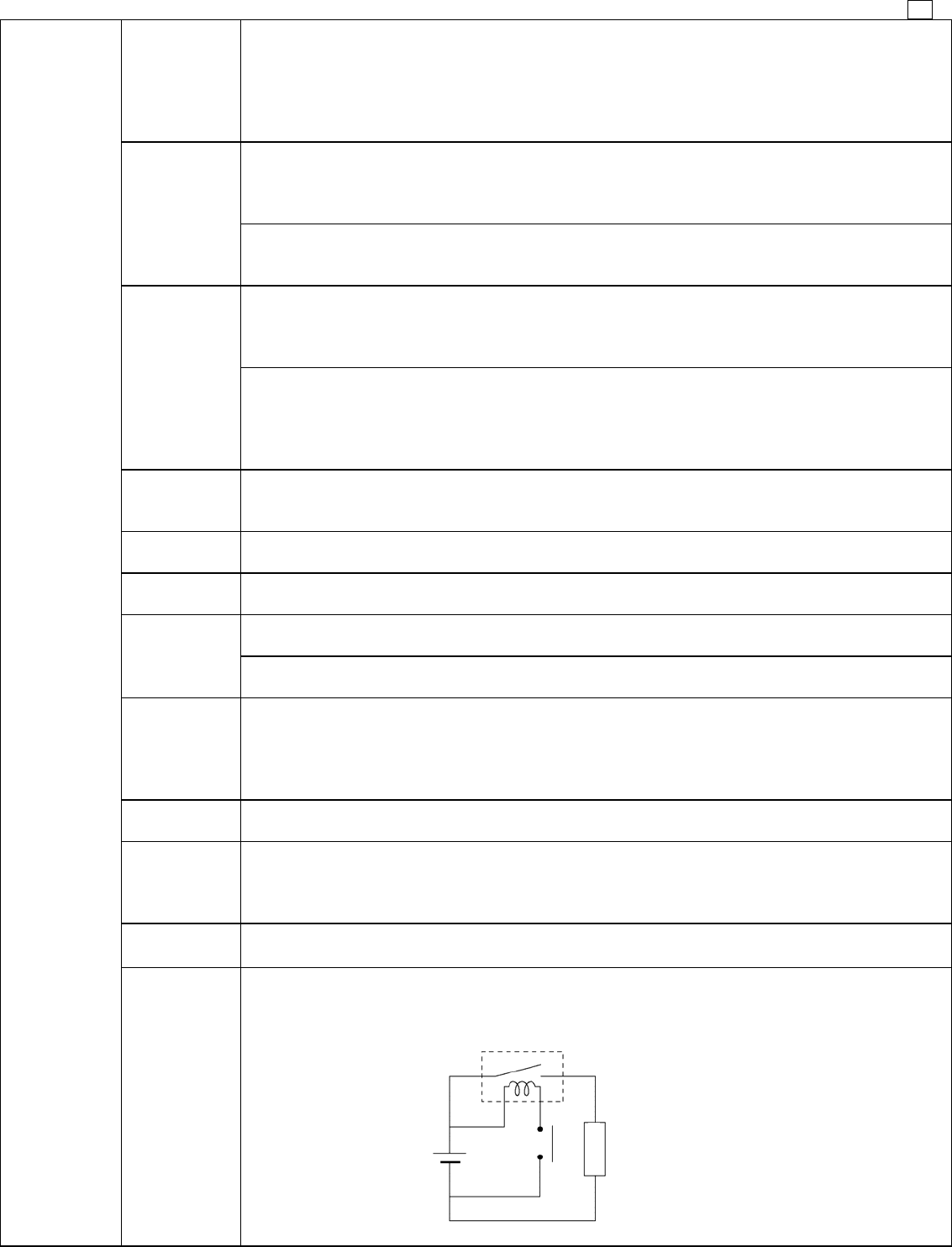

4. Load,

Electrical life

12. Voltage

drop of

power

supply

Under a circuit which inrush current is applied to such as lamps and capacitors, the moment the contact

is closed, voltage drop to the coil, return of relay, or chattering may occur. Note that it may remarkably

reduce the electrical life.

Load