17

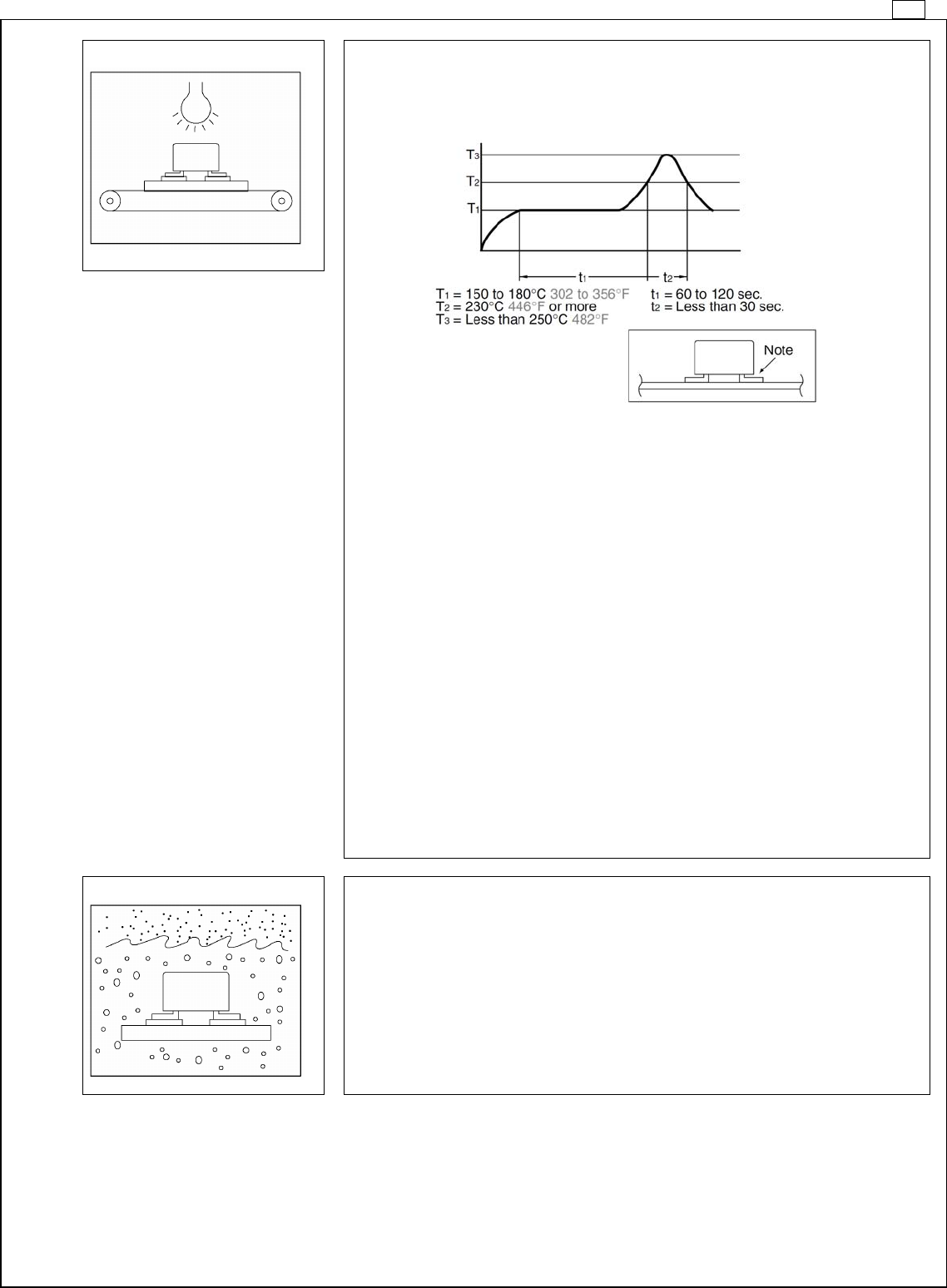

3. Reflow

Reflow soldering under inadequate soldering conditions may result in unreliable

relay performance or even physical damage to the relay (even if the relay is of

surface mount type with high heat resistance).

1.IRS profile

Note: When a soldering technique other than above is to be used (hot air, hotplate,

laser, or pulse heater technique), carefully investigate the suitability of the

technique.

The soldering temperature profile indicates the pad temperature. In some

cases, the ambient temperature may be greatly increased. Examine it under

the specific mounting condition.

2.Manual soldering

Soldering iron tip temperature: 350°C (662°F)

Soldering iron wattage: 30 to 60 W

Soldering time: Less than 3 sec.

3.Others

For other solder methods except for the above (such as hot air heating, hot plate

heating, laser heating, pulse heating, etc.), please check for mounting and soldering

condition before use.

• It is recommended that the soldered pad be immediately cooled to prevent thermal

damage to the relay and its associated components.

• While surface mount relays are solvent washable, do not immerse the relay in cold

cleaning solvent immediately after soldering.

4. Cooling / Cleaning

• While sealed-type (plastic-sealed) relays are solvent washable, do not immerse

the relay in cold cleaning solvent immediately after soldering.

• Use alcohol or an equivalent solvent for cleaning.

• Boiled cleaning is approved for surface mount relays. Ultrasonic cleaning may

cause coil damage or light contact sticking.