Bad example

Bad example

13

15. PCB

mounting

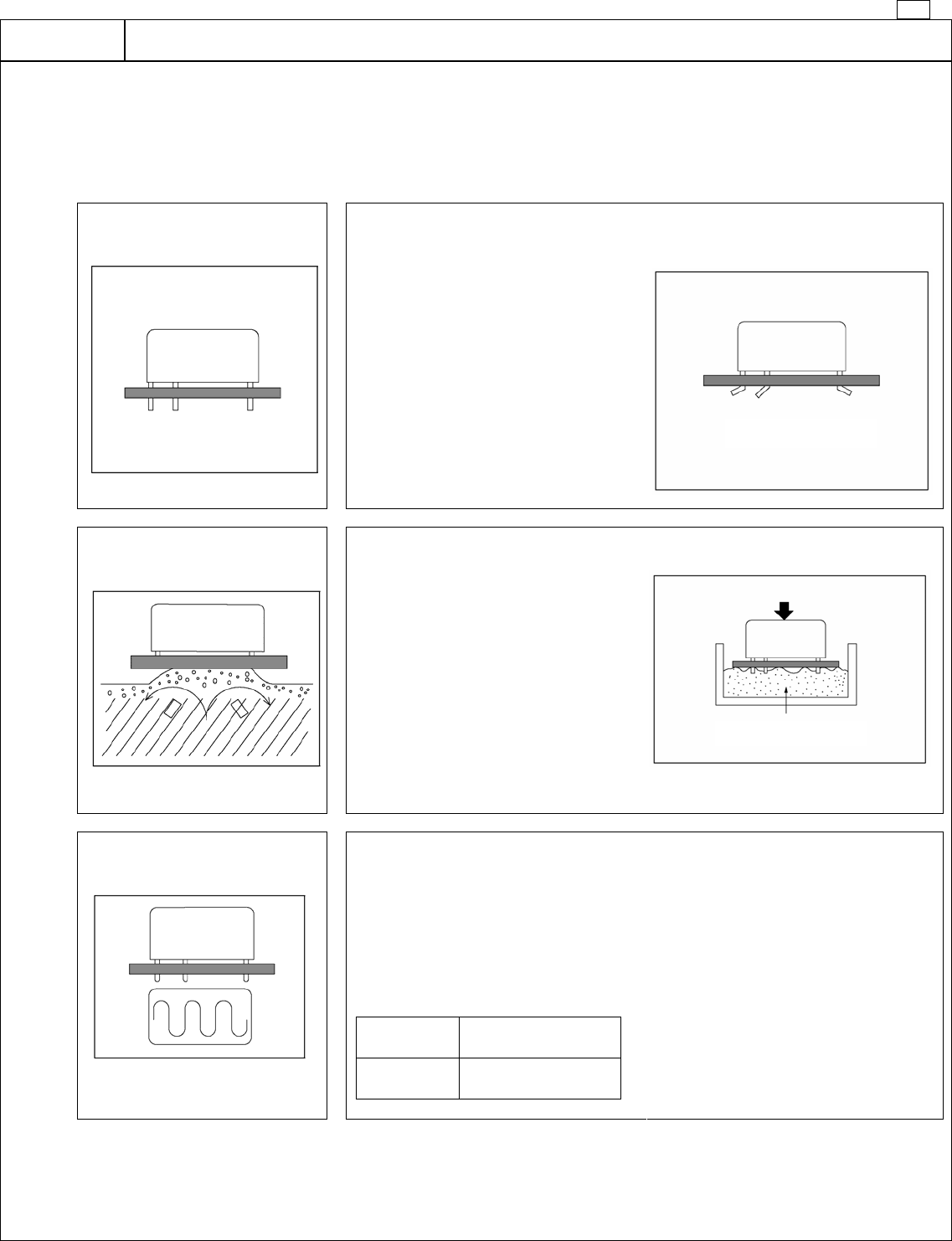

1. Through-hole type

In keeping with making devices compact, it is becoming more common to solder the relay to a PC board along with the

semiconductors instead of using the previous plug-in type in which relays were plugged into sockets.

With this style, loss of function may occur because of seepage into the relay of flux, which is applied to the PC board. Therefore,

the following precautions are provided for soldering a relay onto a PC board. Please refer to them during installation in order to

avoid problems.

The type of protective structure will determine suitability for automatic soldering or automatic cleaning. Therefore, please review

the parts on construction and characteristics.

1. Mounting of Relay

• Avoid bending the terminals to make

the relay self-clinching. Relay

performance cannot be guaranteed if

the terminals are bent.

• Correctly make the PC board according

to the given PC board pattern

illustration.

• Tube packaging for automatic mounting

is available depending on the type of

relay. (Be sure that the relays don't

rattle.) Interference may occur internally

if the gripping force of the tab of the

surface mounting machine is too great.

This could impair relay performance.

2. Flux Application

• Adjust the position of the PC board so

that flux does not overflow onto the top

of it. This must be observed especially

for dust-cover type relays.

• Use rosin-based non-corrosive flux.

• If the PC board is pressed down into a

flux-soaked sponge as shown on the

right, the flux can easily penetrate a

dust-cover type relay. Never use this

method. Note that if the PC board is

pressed down hard enough, flux may

even penetrate a flux-resistant type

relay.

3. Preheating

• Be sure to preheat before using

automatic soldering. For dust-cover

type relays and flux-resistant type

relays, preheating acts to prevent the

penetration of flux into the relay when

soldering. Solderability also improves.

• Preheat according to the following

conditions.

Temperature

120°C/ 248°F or less

(PCB solder surface)

Time

Within approx. 2

minute

• Note that long exposure to high

temperatures (e.g. due to a

malfunctioning unit) may affect relay

characteristics.