Unit 3: Installation

S8400 Series Operator Manual

3-3 PN: 9001160B

PRINTER INSTALLATION

This chapter provides guidance on how to station, connect, and load the printer once unpacked. Following printer

setup, proceded to the next chapter for information on interface selection.

SITE LOCATION

• Stationed away from hazardous materials.

• Stationed within an enclosed structure that conforms to the printer’s enviromental requirements.

• Stationed within operational distance of the host based on interface specifications.

• Stationed to allow unimpeded access to the printer for operation, loading, and maintenance.

INSTALLATION REQUIREMENTS

The printer has five bores in its center frame for the purpose of mounting to a support structure. Refer to the

following list of mounting requirements.

• The support structure must be firmly secured to the floor or production machinery.

• The support structure must be sturdy and stable so as to prevent unnecessary movement or vibration.

• The printer is to be mounted to the support structure using attaching hardware design to accommodate the

printer’s weight, as well as, the prevailing operational and enviromental conditions within the facility.

• A power supply recepticle or junction box is to be properly secured within regulated proximity to the printer.

• The power supply is to be metered condusive to the printer’s design requirements.

• The printer must be installed so that its output side is within the designated distance and height relative to the

applicator.

• Media supply dispensers must be mounted or placed with operational distance of the printer’s input side.

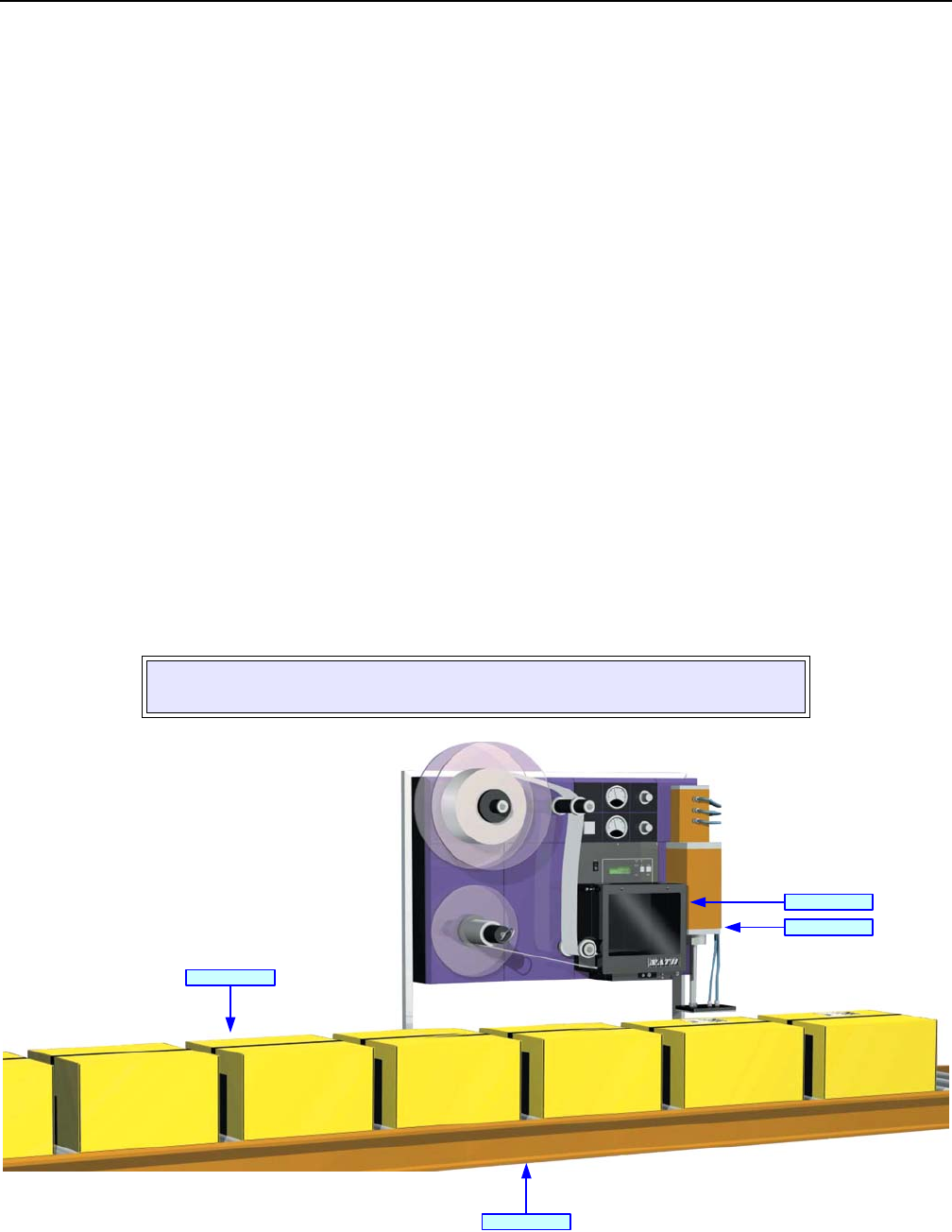

Figure 3-2, Typical Printer/Applicator Process

NOTE: Figures 3-2 and 3-3 are to be used as instructional displays only and are not to

be literally interpretted as precise examples.

Applicator

Printer

Packaging

Production Line