Technical Description Teledyne API Ultrafine Particle Monitor - Model 651

56 07506C DCN6727

Changes in optical alignment, laser power, operating temperatures,

flow rates, presence of water, or optical cleanliness can all reduce

pulse amplitude, therefore the pulse amplitude indicates the

“health” of the WCPC. A peak-sense and hold circuit within the

Model 651 measures the pulse amplitude of 50 particles/sec. The

average pulse amplitude is displayed both numerically and in a bar

graph on the Status screen, and is also included in the data

retrieved from the digital interfaces. The limitation of the Pulse

Height indication is that is requires the presence of at least 50

particle pulses/sec to provide information. The Pulse Height fault

status indication is displayed for particle concentrations over

1000 #/cm

3

with a pulse height of less than 350 mV. When

measuring very low concentrations (<10 #/cm

3

) the Pulse Height

fault may be displayed even though the correct particle

concentration is provided.

Flow System

Refer to Figure 1-2 while reviewing the instrument flow information.

The Model 651 relies on an external vacuum supply to maintain

constant flows through three critical orifices. These independent

flows can be verified by toggling into the different flow modes.

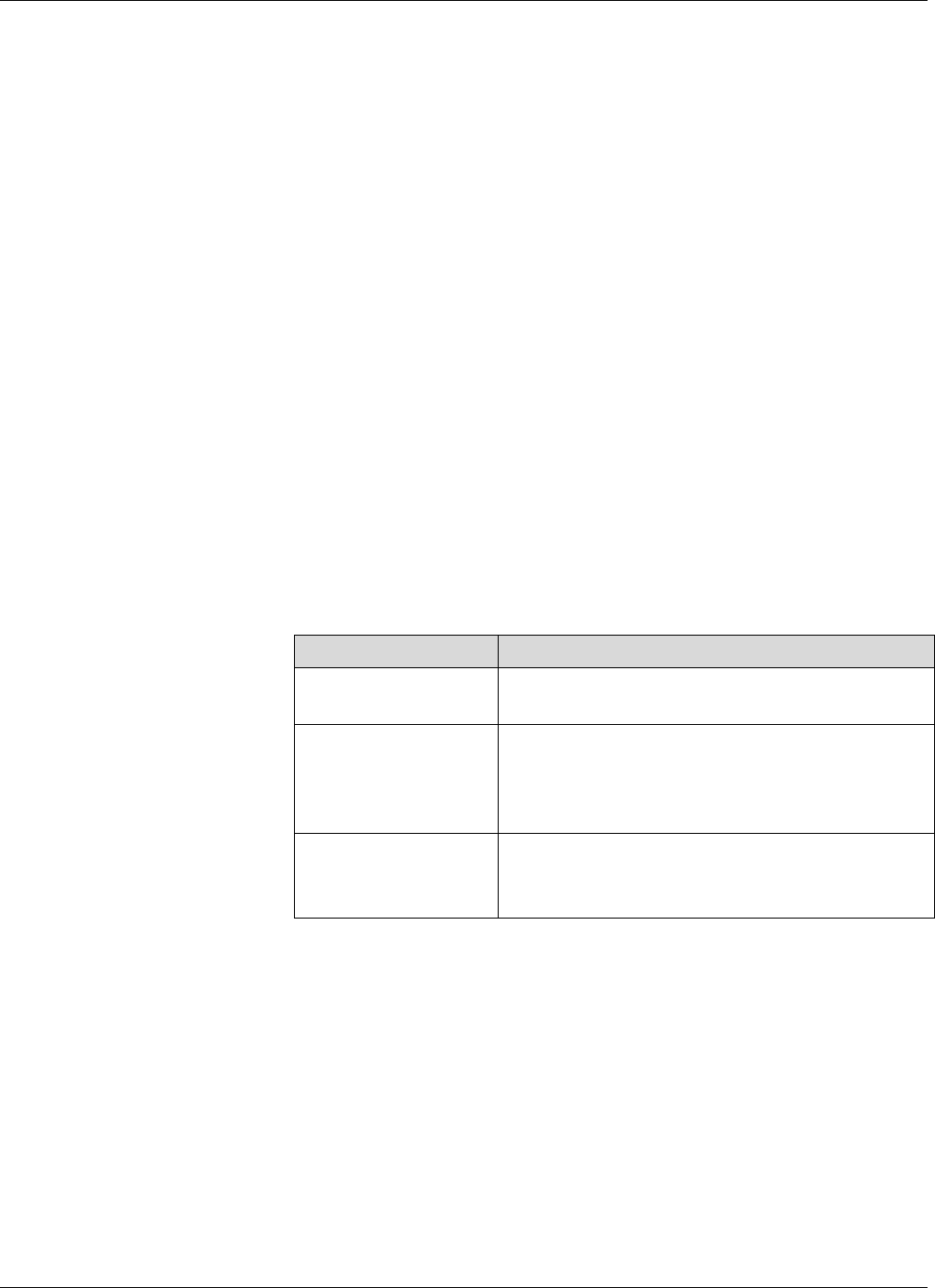

Orifice Description

0.12 L/min aerosol

sample flow mode

Carries the aerosol to be sampled. This is not

user-selectable.

3.0 L/min auxiliary

flow mode

Provides a higher flow rate for use with sampling

systems.

Note: 2.4 L/min auxiliary flow is removed to

leave a transport flow of 0.6 L/min.

0.6 L/min transport

flow mode

Reduces particle losses.

Note: 0.48 L/min transport flow is removed to

leave a sample flow of 0.12 L/min.

The flow rate through the sensor is always 0.12 L/min,

independent of the inlet flow rate setting. Problems with the aerosol

flow can be detected by monitoring the pressure drop across the

nozzle and verifying that the critical orifice pressure is maintained.

Critical Flow

To achieve the 0.12 L/min sample flow through the sensor, an

orifice is used (operated at the critical pressure ratio) to provide a

critical flow. Critical flow is very stable and is a constant volumetric

flow, ensuring accurate concentration measurements despite varied

inlet pressure.