13

CONTENTS

2.1 OVERVIEW

ALS

20x

256

GB

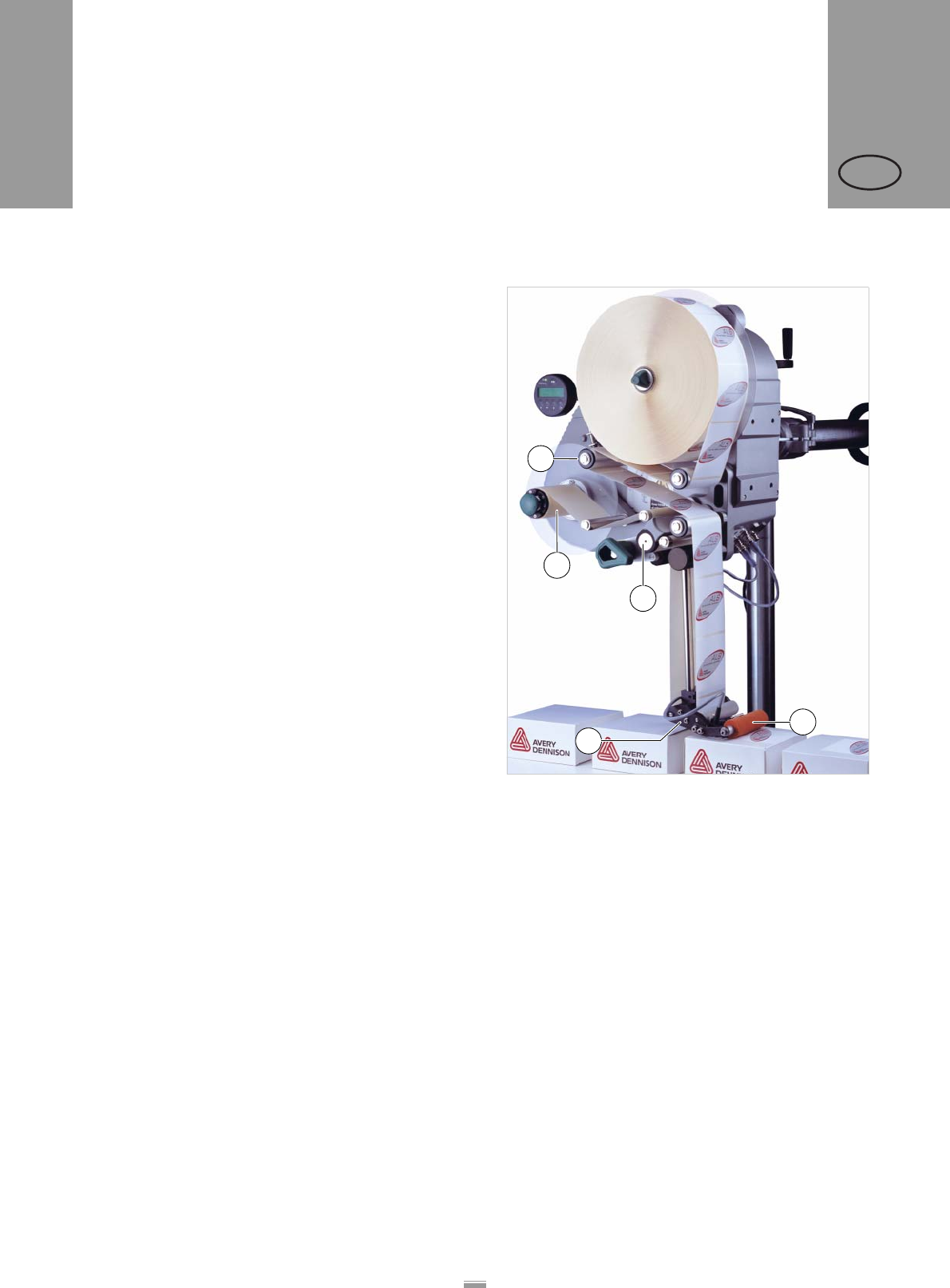

2.1.4 Mode of operation

In labelling mode, the strip is first pulled from the label

roll around the dancer arm [8A], which consistently

maintains even tension in the label strip. The feed roller

[8D] behind the dispensing edge [8C] draws the strip

across the dispensing plate. The label is unfixed from

the backing paper on the dispensing plate and is

pressed onto the product by the pressure roller [8B].

The feed roller drives the label strip forwards the length

of one label and stops until the next product arrives at

the dispensing plate. The strip feed is started by the

product sensor mounted on the conveyor belt. The stop

control provided by the label sensor on the dispensing

edge ensures the feed is halted as soon as a gap is de-

tected between two labels.

The spent backing paper runs from the dispensing

edge around the drive roller [8D] to the rewinder [8E].

The dancer arm regulates the rewinding speed.

The entire operation of the label dispenser is controlled

and monitored electronically. If errors occur, the device

controls output an appropriate notification for the oper-

ator. If necessary, the labelling operating mode is halt-

ed automatically. An electronic signal is output at the

same time. The signal can be fed to an external control-

ler and evaluated.

[8] The ALS20x Label Dispenser is ready for operation in its

idle mode.

A Dancer arm

B Pressure roller

C Dispensing edge

D Drive roller

E Rewinder

D

A

E

B

C