Fault Block Shielded Cable

Table 3 shows the maximum distance between the con-

trol and the high-voltage switches for a range of conduc-

tor sizes and fault-block settings. The table is based on

conductor voltage drop and saturation of the current

sensing transformers in the switch. Lower actuating lev-

els and lower multipliers could allow longer lines.

However, the limitation on switch control cable lengths,

Table 2, preclude their use.

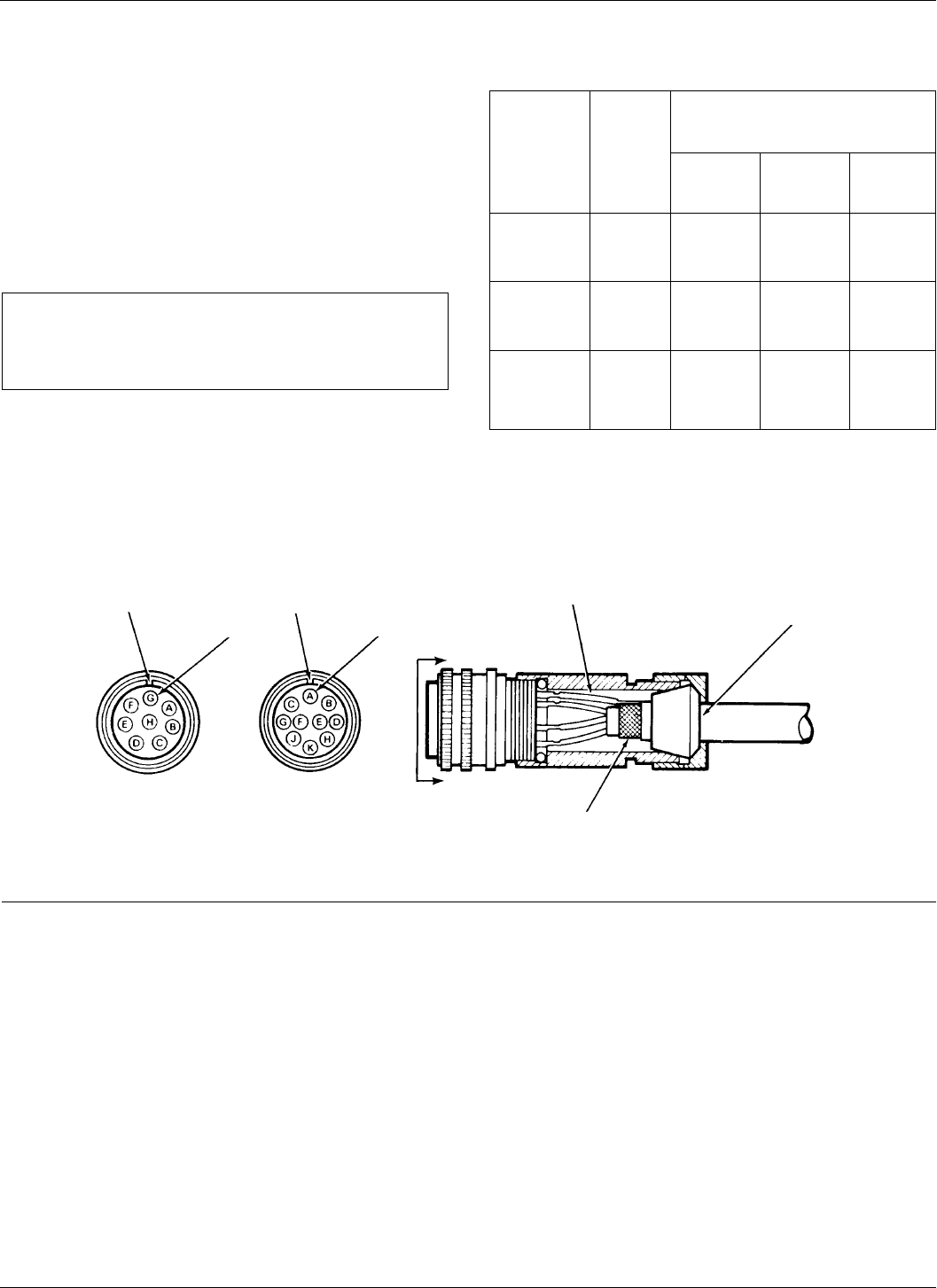

Shielded cable is required between the transfer switches

and the S control for operating the fault block accessory.

The shield must be grounded to the equipment housing

at both the switch and control ends. Shield connections

are made at connector plug pin or socket as shown in

Figure 13. This pin mates with the receptacle pin or sock-

et which is grounded in the switch and in the control as

shown in Figures 6 and 8.

Type S Automatic Load-Transfer Control Installation, Operation, and Maintenance Instructions

14

TABLE 3

Fault Block Cable Limitations

Max. Distance in Feet

Phase Between Switch and

Actuating Con- S Control

Current ductor

Level Size For X 8 For X 6 For X 4

(Amps) (AWG) Multi- Multi- Multi-

plier plier plier

640 18 600 1000 1800

640 16 950 1600 2900

640 14 1500 2550 4600

640 12 2400 4000 7300

448 18 1100 1700 –

448 16 1800 2700 –

448 14 2800 4300 –

448 12 4500 6850 –

320 18 1800 ––

320 16 2900 ––

320 14 4600 ––

320 12 7300 ––

Figure 13.

Fault block cable plug.

KEYWAY

SOCKET A

SWITCH END

STRIP JACKET TO EXPOSE SHIELDING

RUBBER GROMMET

ACCOMMODATES

.50 TO .56 DIA. CABLE

A

A

KEYWAY

CONTROL END

PIN G

SOLDER #16 AWG JUMPER WIRE

FROM SHIELD TO PIN G TO

COMPLETE SHIELD CONNECTION

IMPORTANT: Only shielded cable is to be used on fault

block accessory and is mandatory to validate the

Cooper Power Systems warranty. Use of a non-shielded

cable could result in misoperation.