EPSON Stylus PHOTO 810/820/830 Revision B

Operating Principles Electrical Circuit Operating Principles 49

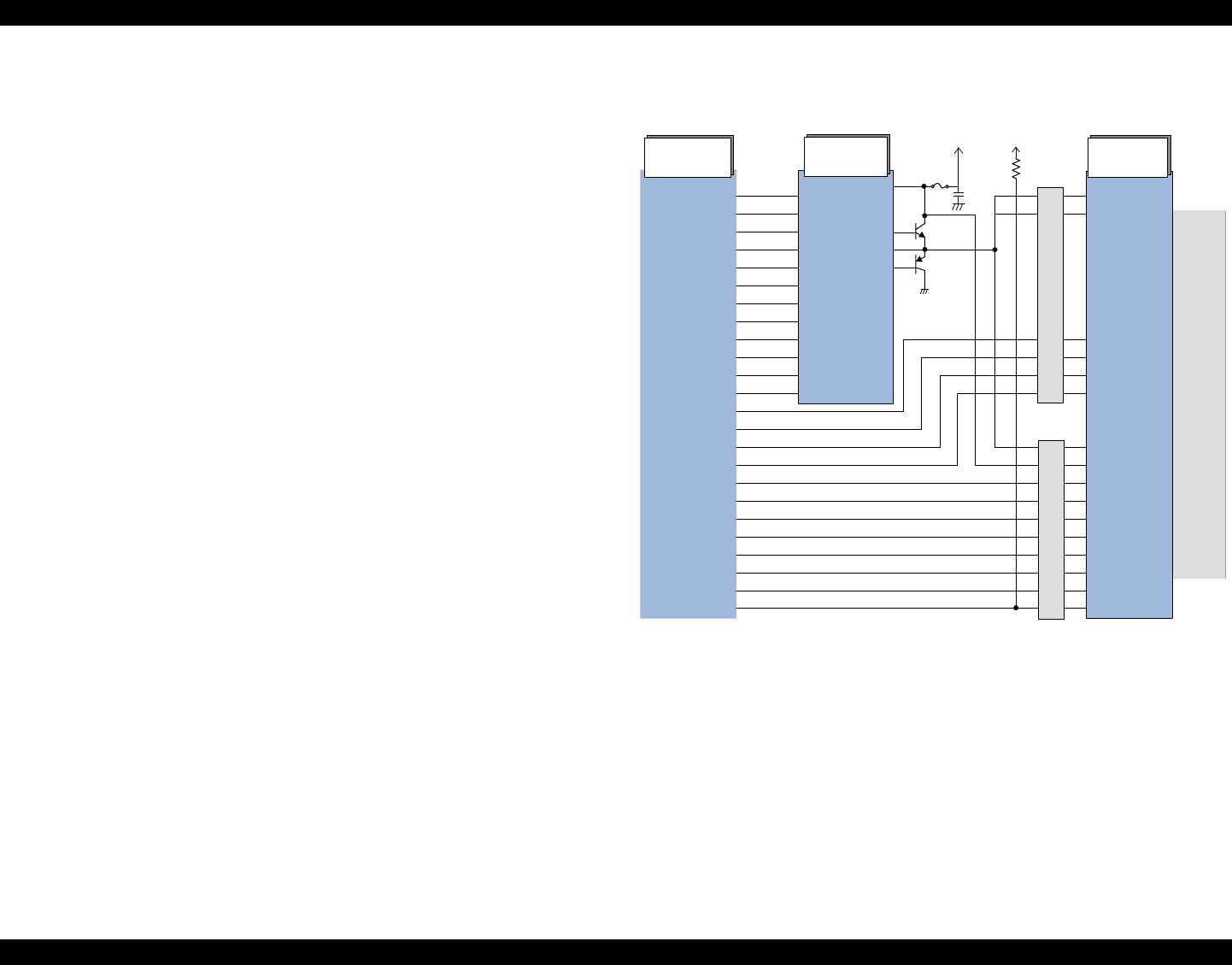

2.2.2.2 Printhead Driver Circuit

The printhead driver circuit consists of the following two components:

Head common driver circuit (Common driver IC19 & Wave amplifier

transistor Q2, Q3)

Nozzle selector IC on the printhead driver

The common driver (IC19) generates a basic drive waveform according to the output

signals from CPU (IC1). The basic drive waveform is amplified by the transistors Q2

and Q3 (the amplified one is called drive waveform.) and then transferred to the nozzle

selector IC on the printhead driver board. Print data is converted to serial data by the

CPU and then sent to the nozzle selector IC on the printhead driver board. Based on the

serial data, the nozzle selector IC determines the nozzles to be actuated. The selected

nozzles are driven by the drive waveforms amplified by the transistor Q2 and Q3. See

refer to Figure 2-19 for the printhead driver circuit block diagram.

Head common driver circuit

The basic drive waveform is generated in the common driver (IC19) based on the

following 12 signal lines output from the CPU (IC1); A0-A4, CLK1, CLK2,

FLOOR, RST, DATA, DCLK, and E.

By the DATA signal output from the CPU, the original data for the basic drive

waveform is written in the memory in the common driver (IC19). The addresses

for the written data are determined by A0-A4 signals. Then, the necessary data is

selected from the address and appropriate basic drive waveform is generated.

Generated basic drive waveform is transferred to nozzle selector IC on the

printhead driver board through the transistor Q2 and Q3 and applied to the nozzle

PZT specified by nozzle selector IC.

Nozzle selector circuit

Printing data is allocated to the six rows (the number of the head nozzle rows) and

converted into serial data by the CPU (IC1). Then the converted data is transferred

to the nozzle selector IC through the six signals lines (HS01 to HS06). Data

transmission from the CPU to the nozzle selector synchronizes with the LAT

signal and SCK clock signal. Based on the transmitted data, appropriate nozzle is

selected and the PZTs of the selected nozzle are driven by the drive waveform

output from the head common driver.

Figure 2-19. Printhead driver circuit

CPU

(IC1)

Common

Driver(IC19)

Nozzle

Selector IC

+4.2V

Head

Drive

Pulse

CN9

CN8

HWA0

HWA1

HWA2

HWA3

HWA4

HWCLK1

HWCLK2

HWFLR

HWRST

HWSDATA

HWSCLK

HWSLAT

HSOCLK

HCH

HSO1 ~ HSO6

HSOCMD

HLAT

HNCHG

C-P32

C-P13

C-P30

C-P34

C-P12

C-P40

COM

COM

SCK

CH

SI1 ~ SI6

SP

COM

VHV

LAT

NCHG

CSCK

COI

CRST

CSDA

CVDD

THM

AO

A1

A2

A3

A4

CLK1

CLK2

FLOOR

RST

DATA

DCLK

E

VCC45

NPNB

FB

PNPB

132

133

134

135

136

127

126

125

124

130

129

128

13

12

21

24

19

20

8

11

10

18

9

6

26

25

24

23

22

3

4

5

6

27

28

1

F1

+3.3V

19

17

15

14

Q2

Q3

15

13

11

9

2

1

2

4

8

6

10

11

12

14

15

13