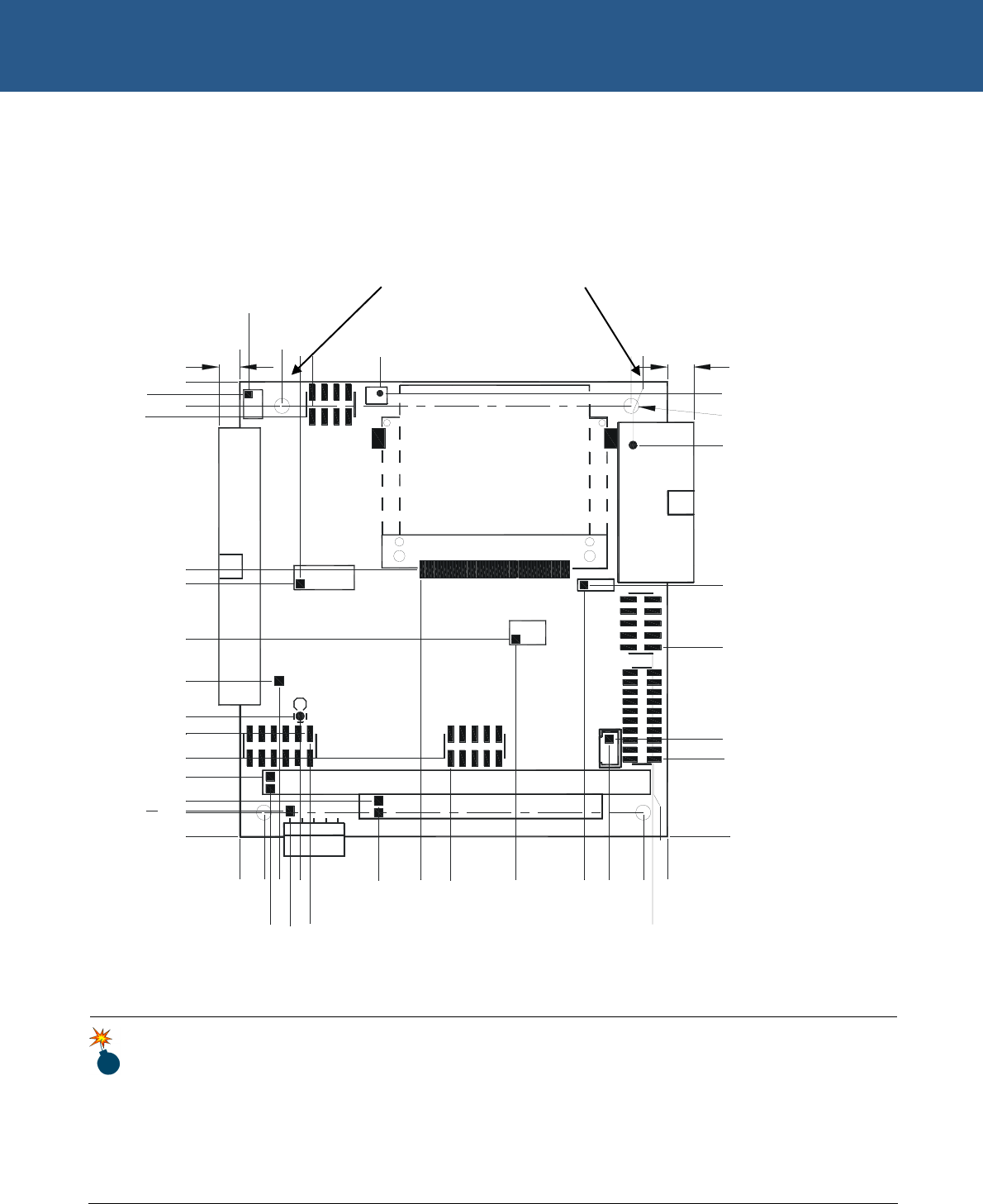

VIPER Technical Manual Appendix C – Mechanical diagram

© 2007 Eurotech Ltd Issue E 103

Appendix C – Mechanical diagram

NOTES

1) ALL CONNECTOR DIMENSIONS ARE TAKEN FROM PIN 1

PL1

PL2

PL3

PL4

PL6

PL7

PL8

PL9

PL10

PL11

PL12

PL5

PL16

JP1

JP3

JP2

A

A

A

A

PL17

0.00

5.08

6.35

8.26

10.51

14.73

29.21

38.16

44.41

58.17

72.53

77.83

85.09

90.17

87.06

87.34

53.09

39.95

16.39

20.65

0.00

82.55

93.47

0.00

5.08

5.44

7.62

12.70

16.54

21.75

32.84

41.72

53.34

56.36

88.61

93.22

95.89

90.80

0.00

8.89

15.24

29.55

82.55

82.93

5.57

1.78

4.44

Ø3.18

FOUR (A) HOLES

JP4

12.7012.70

25.40

When mounting the VIPER use only M3 (metric) or 4-40 (imperial) screws. The mounting pad

is 6.35mm, 0.25” and the hole is 3.175mm, 0.125”, so ensure any washers fitted are smaller

than the pad.

Using oversized screws and washers, or tooth locking washers, can cause short circuits and

over-voltage conditions.

We recommend that you use a Loctite screw thread lock or a similar product over tooth

locking washers.

Chassis ground mounting positions

Unit of measure = mm (1inch = 25.4mm)