9 - 25 9 - 25

MELSEC-Q

9 LOADING AND INSTALLATION

(2) Wiring of I/O equipment

(a) Insulation-sleeved crimping terminals cannot be used with the terminal block.

It is recommended to cover the wire connections of the crimping terminals

with mark or insulation tubes.

(b) The wires used for connection to the terminal block should be 0.3 to 0.75mm

2

in core and 2.8mm (0.11 inch) max. in outside diameter.

(c) Run the input and output lines away from each other.

(d) When the wiring cannot be run away from the main circuit and power lines,

use a batch-shielded cable and ground it on the PLC side.

In some cases, ground it in the opposite side.

Input

Output

PLC

Shielded cable

Shield

DC

RA

(e) Where wiring runs through piping, ground the piping without fail.

(f) Run the 24VDC input line away from the 100VAC and 200VAC lines.

(g) Wiring of 200m (686.67 ft.) or longer distance will give rise to leakage currents

due to the line capacity, resulting in a fault.

Refer to Section 11.5 for details.

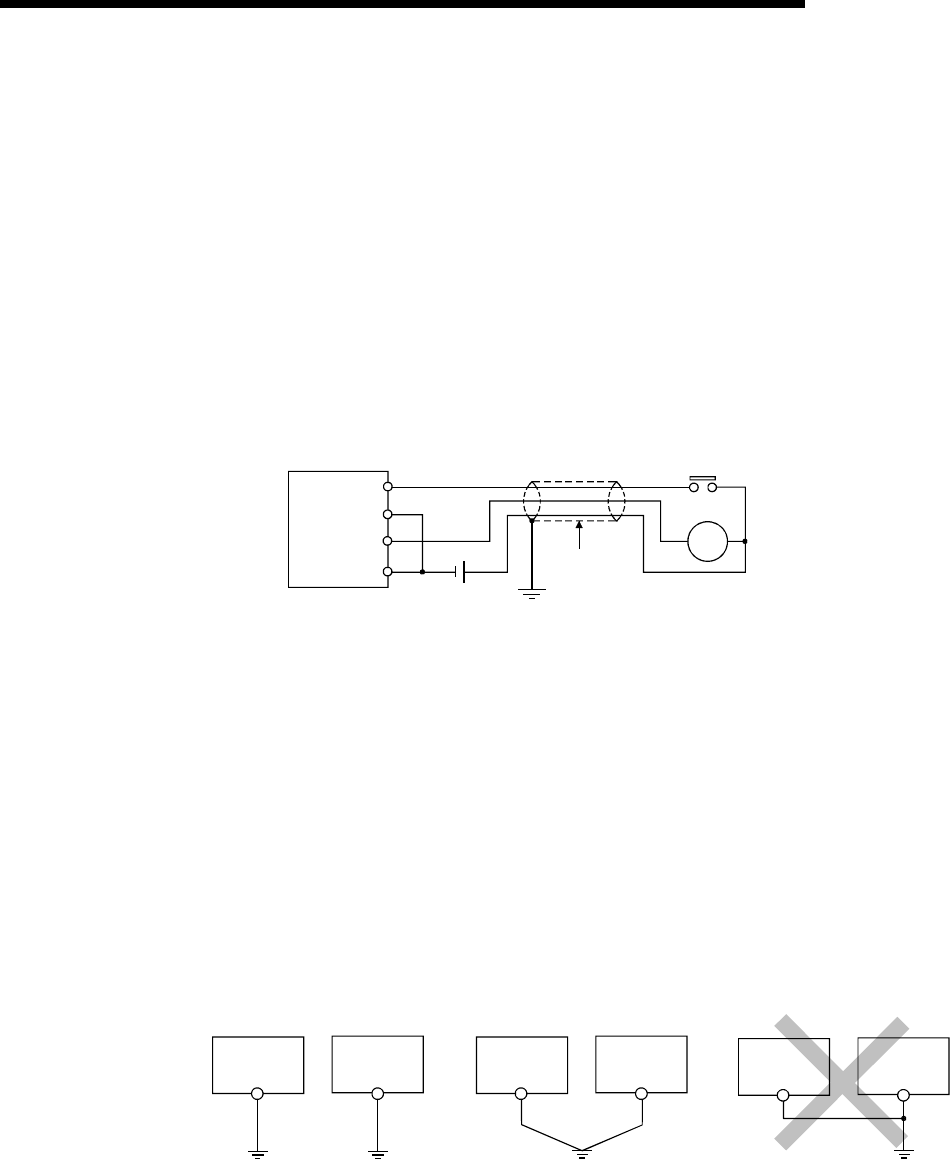

(3) Grounding

To ground the cable, follow the steps (a) to (c) shown below.

(a) Use the dedicated grounding as far as possible.

(b) When a dedicated grounding cannot be performed, use (2) Common

Grounding shown below.

PLC

Another

equipment

grounding

(1) Independent grounding.....Best (2) Common grounding.....Good (3) Joint grounding.....Not allowe

d

PLC

Another

equipment

PLC

Another

equipment

grounding

(c) For grounding a cable, use the cable of 2 mm

2

or more.

Position the ground-contact point as closely to the sequencer as possible, and

reduce the length of the grounding cable as much as possible.