2 - 10

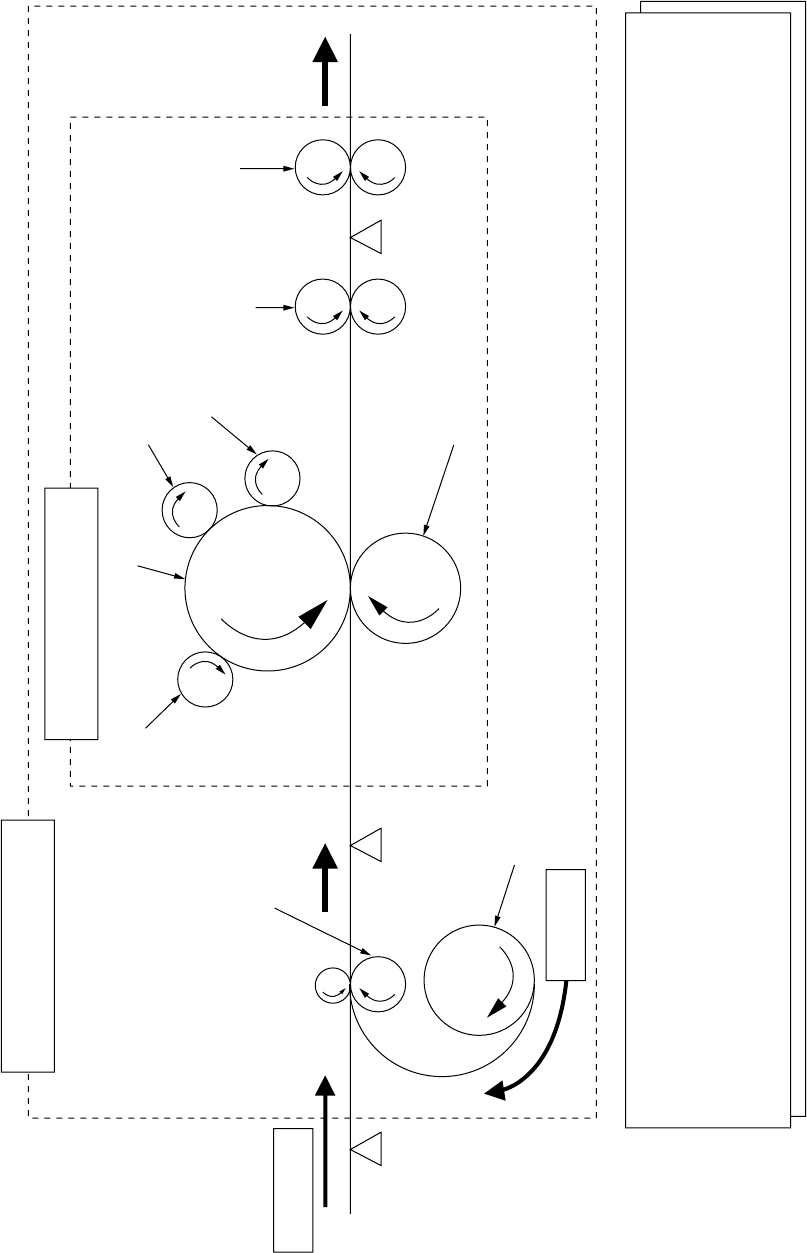

Figure 2-4 Schematic Drawing of OKIPAGE4w Plus/4m Paper Feeding

Exit roller

Heat roller

Transfer roller

Cleaning roller

CH roller

Drum roller

Developing roller

Outlet

sensor

Paper sensor

Hopping roller

TRAY printing

Feed roller

Manual

feed

sensor

Manual printing

2

Roller to be driven by reverse

rotation of pulse motor (Main)

1

Motor to be driven by normal

rotation of pulse motor (main)

Roller control by pulse motor (main)

1

Normal rotation of pulse motor (main): Drum roller, transfer roller, cleaning roller, CH roller, developing roller, heat roller, exit roller rotation

2

Reverse rotation of pulse motor (main): Drum roller, transfer roller, cleaning roller, CH roller, developing roller, heat roller, exit roller, feed roller,

hopping roller rotation

Hopping operation from the tray, however, is performed when the electromagnetic clutch is turned on.