231

Responding to Displayed Error Messages Section 7-2

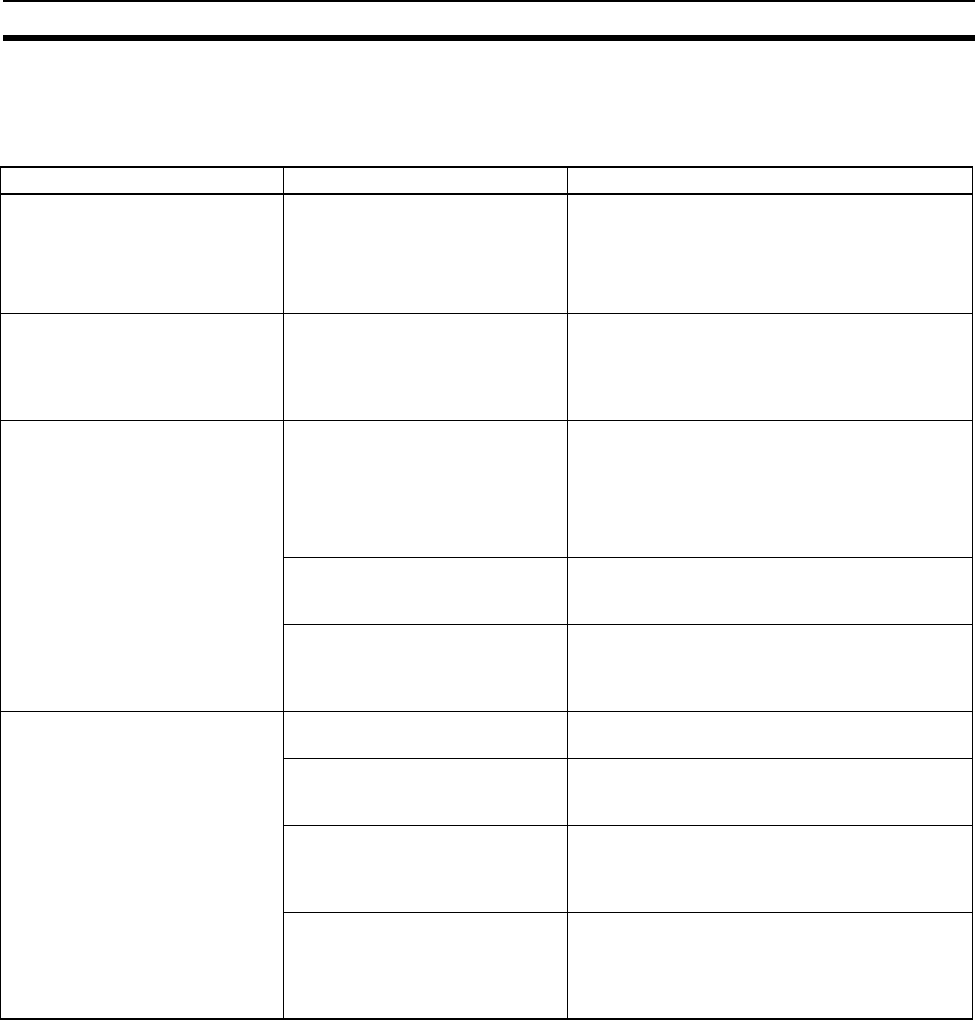

7-2-2 Errors Occurring during Operation and Their Remedies

The table below shows the errors that can occur during operation of the

NT631/NT631C and their remedies.

Message Cause Remedy

[Address Setting Error]

Addressing Error exists in the

Screen.

Correct address setting by the

Support Tool.

The host side allocated words and

bits set with the Support Tool are

incorrect.

Set correct words and bits after checking the area

used at the host side by referring to PLC Memory

Map in Appendix D of the Reference Manual or

the Operating Manual for the PLC being used.

[Memory Table No. Error]

Memory table No. is out of limit.

Correct the table No. by the Sup-

port Tool.

The memory table number set

with the Support Tool is outside

the range for the number of mem-

ory tables set in the system mem-

ory.

Either increase the number of memory tables in

the System settings under PT Configuration at

the Support Tool, or set the memory table number

again within the established range.

[Programming Console Error]

Setting of Programming Console

Function is inadequate. It can be

caused by:

• This PLC does not support Pro-

gramming Console Function.

• Protocol mismatch. Set the PLC

to NT Link.

• “PROGRAMMING CONSOLE” is

connected to PLC.

The communications settings are

incorrect.

Set the communications method/communica-

tions port as follows when using the Programming

Console function.

• With C-series PLCs: 1:1 NT Link

• With CS/CJ-series PLCs:

1:N NT Link (standard or high-speed)

The PLC used does not support

the Programming Console func-

tion.

Not all PLCs support the Programming Console

function. Check the model of the PLC you are

using. (6-12 Programming Console Function)

A Programming Console is con-

nected.

It is not possible to use a Programming Console

and the Programming Console function at the

same time. Disconnect the Programming Con-

sole.

[Programming Console Error]

Programming Console Function

does not RUN. It can be caused

by:

• Connecting cable is faulty.

• “PROGRAMMING CONSOLE” is

connected to PLC.

• Protocol mismatch between the

PT and PLC. Set the PLC to NT

Link.

The connecting cable is defective. Check the cable connection and perform a con-

ductivity test. If there is a fault, replace the cable.

Malfunction due to external noise Carry out grounding work in accordance with the

conditions by referring to 3-1-4 Grounding,

page 34.

A Programming Console is con-

nected.

It is not possible to use a Programming Console

and the Programming Console function at the

same time. Disconnect the Programming Con-

sole.

The communications conditions at

the PLC have been changed in

accordance with the NT631/

NT631C Programming Console

function.

Set the communications conditions at the PLC to

match the conditions set in the System Menu.