151

[Connections and Settings in Torque Control Mode]

Connections and Settings in

Torque Control Mode

Parameters for Speed Control

52 –2047

– 2047

[0]

0.3mVVelocity

command

offset

• This parameter adjusts offset of external analog speed command system

including the host device.

• Offset volume will be approximately 0.3mV per a set value “1”.

• To adjust offset, there are 2 ways of (1) manual adjustment and (2) auto

-

matic adjustment.

1) Manual adjustment

• When you make offset adjustment with the driver only:

Using this parameter, set a value that prevents the motor from rotat-

ing, after you have correctly input 0V in torque command input

(SPR/TRQR) (or connected to signal ground).

• When the host device establishes a position loop:

With servo locked, using this parameter, set a value so that deviation

pulse will be zero.

2) Automatic Adjustment

• For details on operating instructions in automatic offset adjustment

mode, refer to “Details of Execution Display of Auxiliary Function

Mode” of Preparations volume on page 66.

• When you execute automatic offset adjustment, result will be reflec-

ted in this parameter Pr52.

Parameter

No.

Setting

range

Parameter Name Unit Function/Description

Default setting is shown by [

]

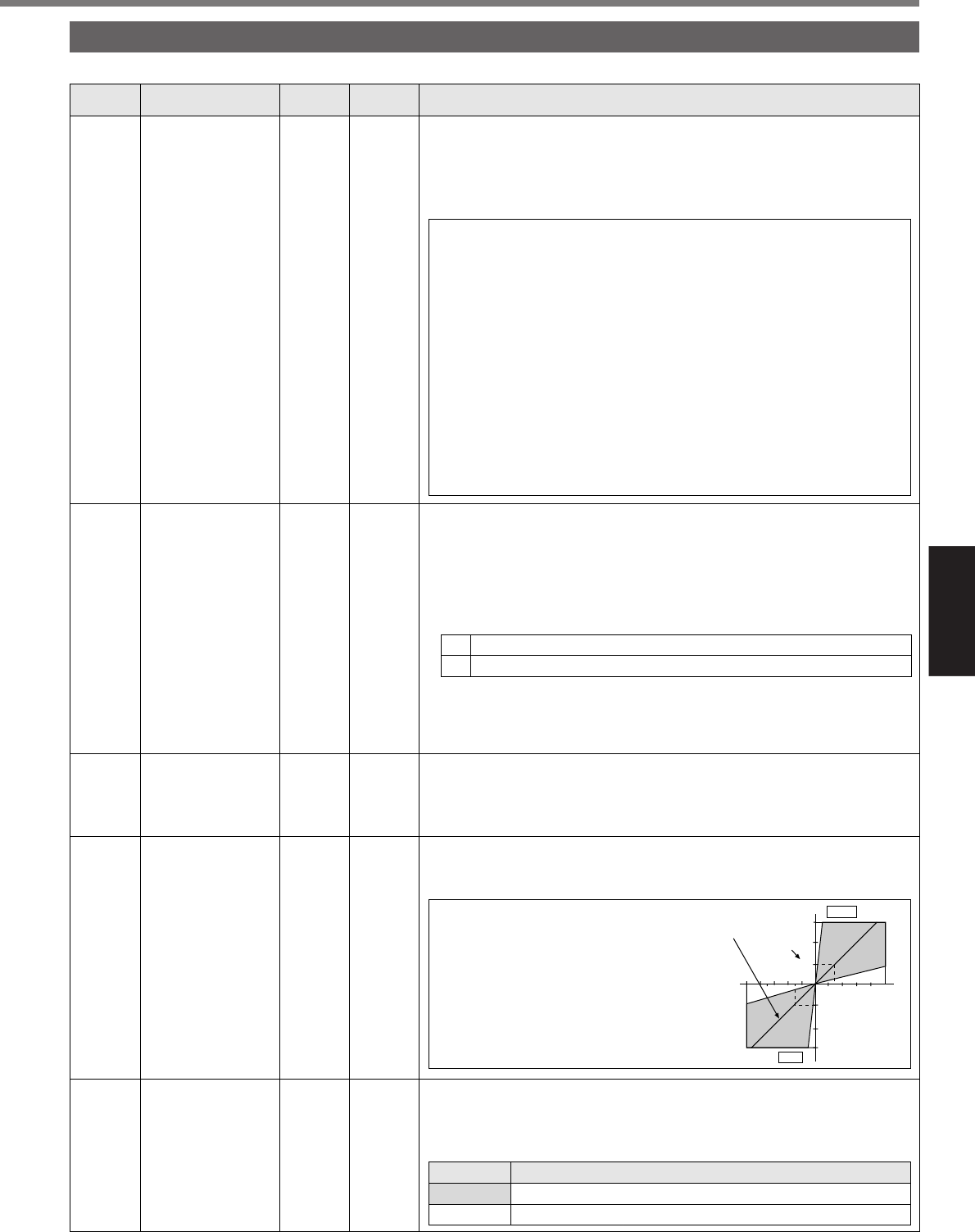

56

–20000

– 20000

[0]

r/min4th internal

speed

The parameter directly sets the 1st to 4th speed of internal command

speed of when setting of internal speed has been enabled with the para

-

meter “speed setting internal/external switching” (Pr05), to Pr53 to Pr56

,

respectively, in the unit of [r/min].

<Caution>

Polarity of settings shows that of internal command speed.

Pr56 is a value of speed limits in torque control mode.

You should set this parameter in a range of rotational speeds of the

motor to be used.

+

–

CCW direction viewed from the edge of axis for (+) command

CW direction viewed from the edge of axis for (-) command

0 – 500

[300]

r/min

57 JOG speed set up

The parameter directly sets JOG speed in JOG run in “motor trial run

mode” in terms of [r/min].

For details on JOG function, refer to “Trial Run (JOG)” of Preparations vol

-

ume on page 68.

5D 0 – 1 –Torque command

input inversion

The parameter inverts polarity of the torque command input signa

l

(TRQR: CN X5 14-pin).

In speed/torque switching mode (when Pr02 is 5), torque command inpu

t

under torque control will be 16-pin of the connector CN X5.

Direction of Generation of Motor Torque

CCW direction viewed from the edge of axis for (+) command

CW direction viewed from the edge of axis for (+) command

Setting value

[0]

1

5C 10 – 100

[30]

0.1V/

100%

Torque command

input gain

The parameter sets a relationship between voltage applied to the torque

command input (TRQR: CN X5 14-pin) in torque control mode and gener

-

ated torque of the motor.

• Setting is in the unit of [0.1V/100%]

and used to set a value of input vol-

tage necessary for calculating rated

torque.

• At a factory setting of 30, the relation-

ship will be 3V/100%.

Rated

Torque

Torque

Setting of

Shipment

Time

Command

Input Voltage

2

-2-4-6-8-10V

100

100

200

300[%]

200

300[%]

46810V

CW

CCW