Users Manual Model 656/636 Appendix D • 69

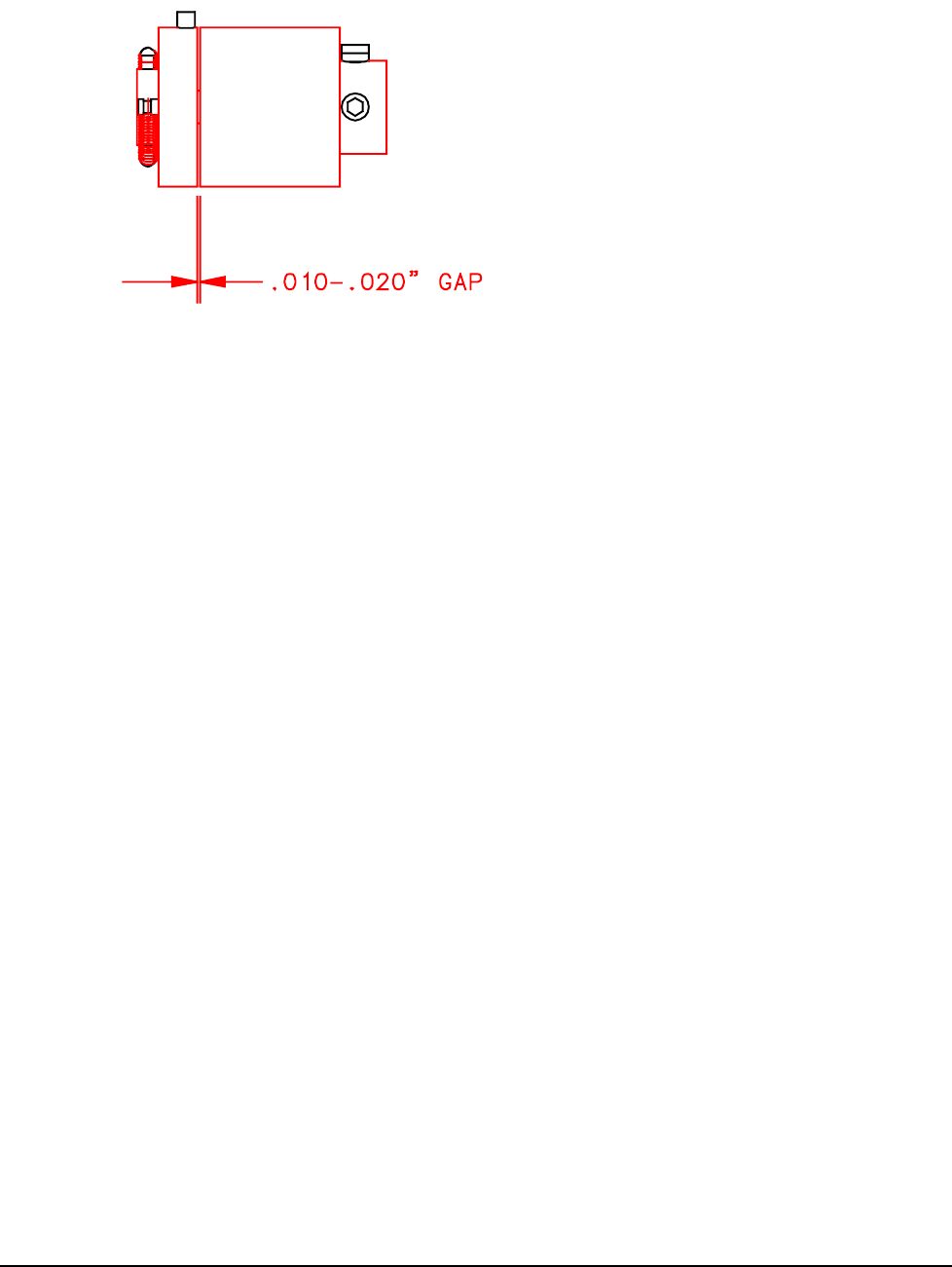

• There should be a .010-.020 gap (for roller clutch only) between the two clutch pieces.

• (Test on the solenoid test box.) The knife must cut both fabric and card stock. The solenoid

should operate on both the high and low settings.

• Excessive motor drag must be minimal at start/stop and while running. Replace or repair

problem component. On old knife assemblies, there are bronze bushings in outer support. They

may be causing a bind. Ream bushing and retest. (Do not ream if it is a roller bearing.)

• (Rev 1) Pre-load setting adjustment. While motor is running, not while cutting, loosen set

screws on “pac-man” and rotate the rotary blade clockwise, mark the stopping position on the

“pac-man”, rotate counterclockwise, mark the “pac-man”, then rotate the blade to the middle of

the two marks and tighten the set screws.

• (Rev 2) All new knife assemblies have a blue clutch. The clutch outer race bushing has an I.D.

of .500 and the 2 extension springs are .012 dia wire.

• (Rev 2) The 2 extension springs on all rebuilt clutches must have the .009 dia. wire springs

replaced with .012 wire springs.

• (Rev 5) Replace Knife Actuator 357020, if it is worn or if there is a “bulge” at the 90-degree

bend.

• (Rev 6) Changed feeler gauge tolerance from .047 MIN