Unit 3: Installation

CT4i Series Operator Manual 3-6

PRINTER INSTALLATION

This chapter provides guidance on how to station, connect, and load the printer once unpacked. Following printer

setup, proceed to the next chapter for information on interface selection.

SITE LOCATION

• Station the printer on a solid flat surface.

• Station it away from hazardous materials or dusty environments.

• Station it within operational distance of the host computer, within interface cable specifications

MEDIA SELECTION

The size and type of the labels or tags to be printed should have been taken into consideration before printer

purchase. Ideally, the media width will be equal to, or just narrower than, the print head. Using media that does not

cover the print head will allow the platen roller to tread on it and wear it out. The media edge will also wear a groove

in the platen roller affecting print quality.

MEDIA LOADING: ROLLED PAPER

There are two general label types that may be loaded and used; rolled and fan-folded. Each of those types may

again be defined by whether their print application is direct thermal or thermal transfer. Those factors determine

how the media is loaded and if ribbon stock is loaded at all.

Thermal transfer media requires the use of ribbon stock for print application. In such a scenario, it is the ribbon

stock (carbon paper) that contains the ink that will be transferred to the media. Direct thermal media has a coating

on the surface that is made visible through the application of heat from the print head. Rolled media of standard

diameter is loaded within the printer and suspended by the media holder.

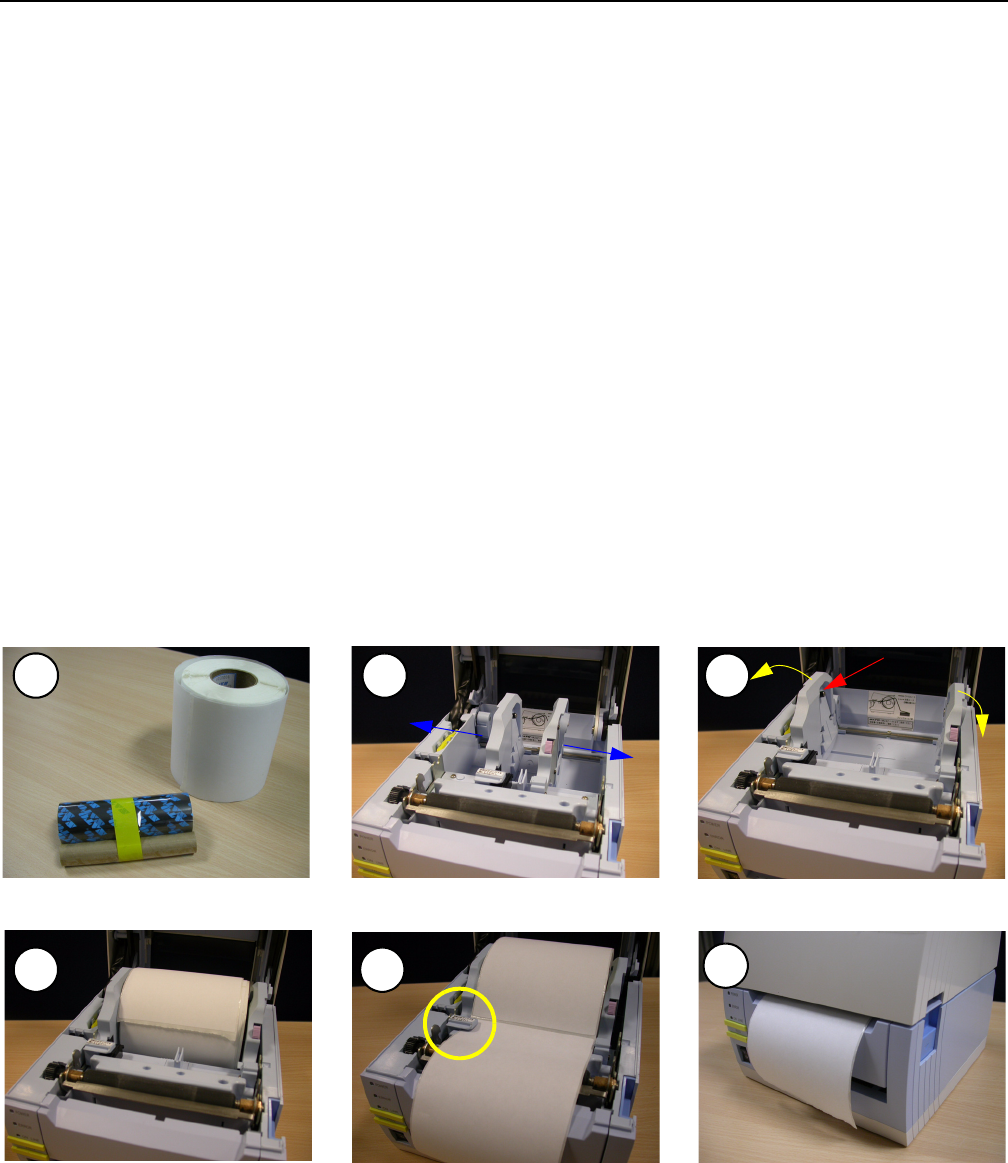

Figure 3-3a, Rolled Label Loading

Load the label roll. Its core should

rotate freely over the black rollers.

Get the media ready. Press the label guide release

knob and pull the guides apart.

Push the left label guide’s tab

outward before loading labels.

Pull the paper under the label

sensor, out to front of the printer.

Close the cover. Direct thermal

printing is now possible.

1 2 3

black roller

4 5

6