Unit 5: Troubleshooting

CT4i Series Operator Manual 5-4

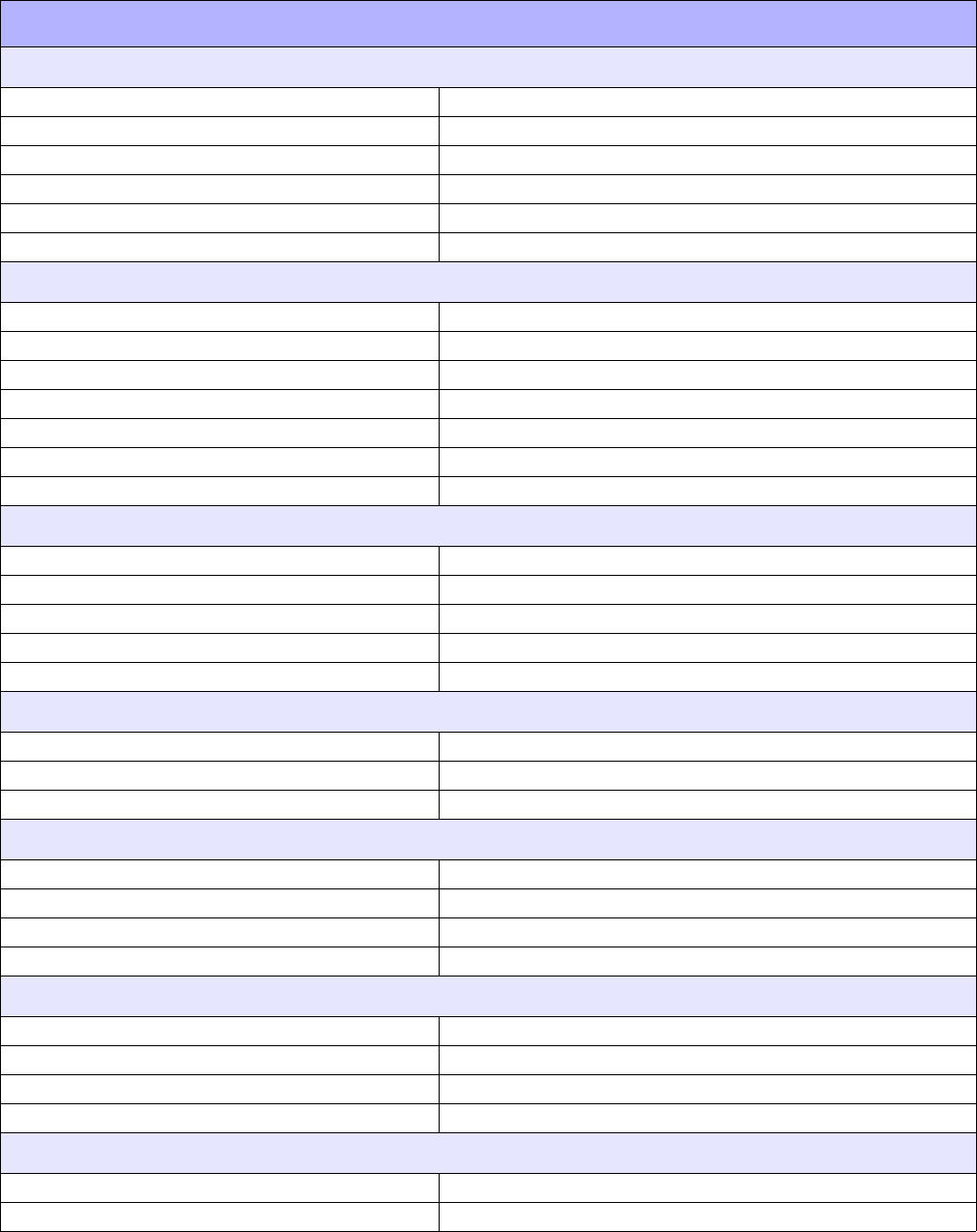

TROUBLESHOOTING TABLE

IMAGE VOIDS

Dirty print head Clean print head

Damaged print head Replace print head

Damaged electronics Replace circuit board

Damaged or worn roller Replace rollers

Poor label quality Use higher quality media

Ribbon stock and media are mismatched Consult with media supplier. Use only SATO-certified media

RIBBON WRINKLING

Poor head alignment Adjust head balance and alignment

Excessive temperature setting Adjust temperature

Poor ribbon tension Adjust tension as required

Worn roller Replace as necessary

Foreign material on print head and/or rollers Clean as required

Foreign material on labels Use higher quality media

Damaged print head Replace print head as required

LIGHT PRINT IMAGES

Low print head energy/darkness Adjust darkness level

Low print head pressure Adjust head pressure and/or balance

Foreign material on print head Clean print head and rollers

Improper head alignment Align print head as required

Excessive print speed Reduce print speed setting

UNEVEN PRINT DARKNESS

Unbalanced print head Adjust head balance

Worn rollers Replace rollers as required

Dirty print head Clean print head

MEANDERING MEDIA

Incorrectly loaded media Ensure correct loading

Improperly adjusted media guides Adjust as required

Unbalanced print head Adjust as required

Worn rollers Replace as required

NO LABEL MOVEMENT

Loose or broken timing belt Replace or adjust as required

Incorrect label sensor selected Check printer configuration for proper sensor selection

No voltage output Replace fuse. Test power supply and replace as required

Drive motor not operating Ensure wiring harness connection. Replace as necessary

LED FIELD ILLUMINATED BUT NO DISPLAY AT ALL

Power supply issues Ensure cable properly connected. Check/replace power supply

Incorrectly positioned display potentiometer. Adjust as required