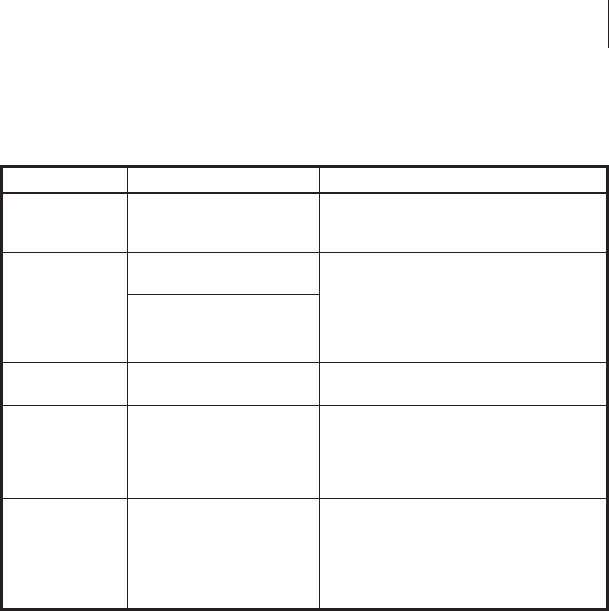

Printer Status Sensors

The printer contains several status sensors. These sensors alert the operator

to various conditions by either stopping the printing or turning on an LED.

Sensor What it Monitors How it Works

Printhead

sensor

Checks the open/ closed

status of the printhead

lever.

If the printhead is open, the

PRINTHEAD LED flashes.

Media sensor

(See Getting

Ready to Print

to adjust this

sensor.)

Checks for proper

media loading.

If you run out of paper, the

PAPER/RIBBON LED will turn on.

If non-continuous media

is used, sets label length

for individual labels.

Ribbon sensor

Monitors the presence

of ribbon.

If you run out of ribbon, the PAPER/

RIBBON LED flashes.

Label available

sensor (Peel-

Off option

required. See

Figure 25.)

In Peel-Off mode, it

checks to see if a label

is available.

Once a label prints, it will pass

between the two parts of this sensor

and cause the printer to pause.

When the label is removed, printing

resumes.

Backing rewind

spindle full

sensor (Peel-

Off option

required. See

Figure 26.)

Senses when the

backing rewind spindle

is full of used backing

material.

When the spindle is full, the

PAPER/RIBBON LED flashes.

S400 & S600 User’s Guide 43

51