:ANAPURNA XL² OPERATOR MANUAL

AB]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]

17

]

8/08/2008

]

7

77

7.

. .

. Printing Table

Printing TablePrinting Table

Printing Table.

..

.

7.1. General information

- Woven Conveyor belt

- Transport is done by a step-motor

- On the table are 4 vacuum-zones with a variable strength.

The table is evenly divided in 4 compartments. The 2 most

right compartments are driven by ring blower number 1;

The 2 most left compartments are driven by ring blower number 2.

The ring blower switch can be switched on in that order.

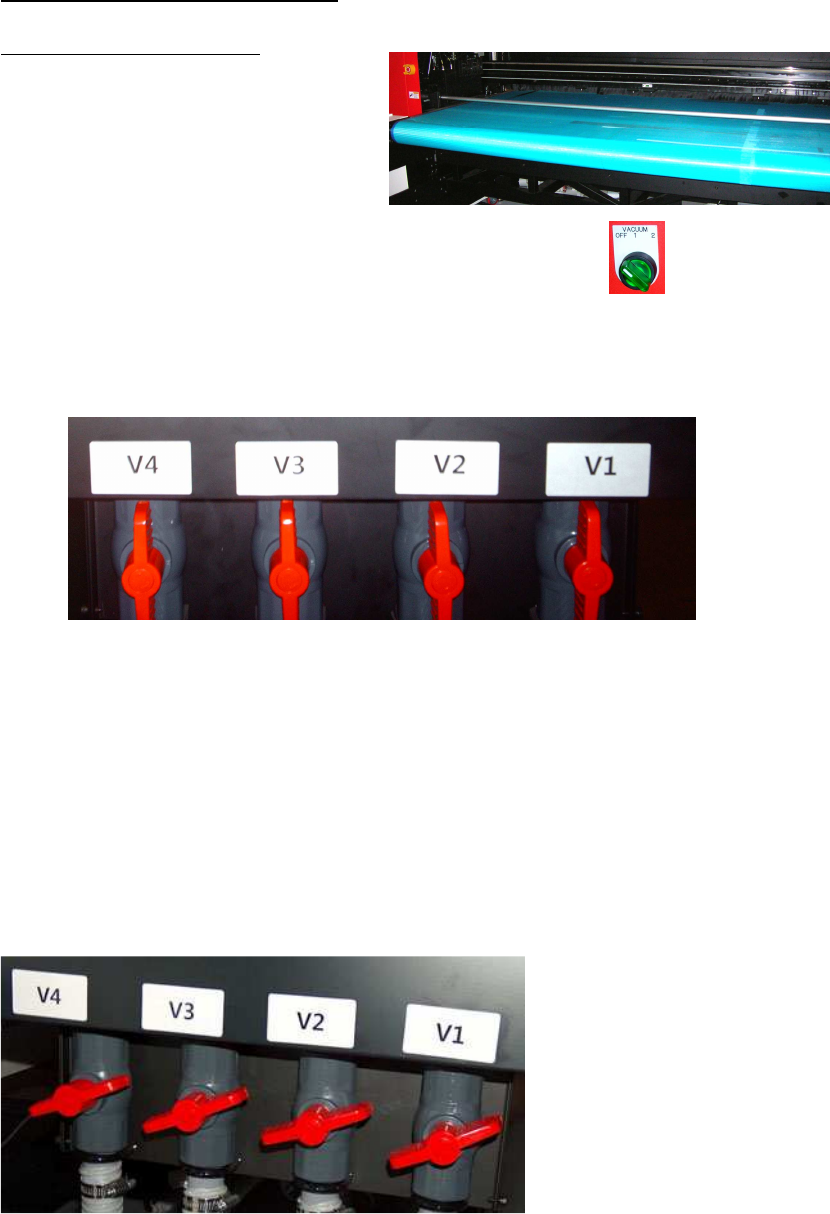

- The vacuum of each compartment can be lowered by closing the manual air valves

located at the rear right side.

- The valve numbers V1 till V4 are numbered from home position (V1) till purge

position (V4). The border of each compartment is indicated with a yellow sticker

on the box beam.

It is very important to set the air valves depending on the media width and media

type that you are using;

As a general rule, one has to close the corresponding air valve to the 30 degrees

angle position (so close the valve for 2/3 of its range) if the corresponding table

compartment is completely covered by the media. The valve of a partly covered

compartment has to stay completely open (upright position as shown in the picture

above).

Fail to do that will have as result that flexible media can get crunched up at the rear

side of the vacuum table due to a too high vacuum and can cause a head crash if the

ripples are coming under the heads.

Air Valve position if all 4 compartments are fully covered (full width media).

More details for specific roll-to-roll media are given at the end of this manual.