Chapter 4 Media (Paper) and Ribbon

-

29

-

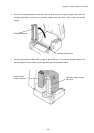

4.6 Media sensor adjustments

Laterally adjustable upper and lower media sensors are equipped; the upper media sensor, i.e. the

transparent sensor (light-receiving device) detects the presence of gaps between labels, center-punched

holes or corner-with-a-radius cuts on the tags, and the lower media sensors, i.e. one reflective sensor

(light-receiving device) detects the presence of black marks on the labels or tags and other two

light-emitting devices work for all light-receiving devices. Therefore, both upper and lower media sensors

are used to detect gaps, holes or cuts on the media while the lower media sensor only is used to detect

black marks on the media (no upper media sensor is used).

Adjust sensors as follows:

1 Perform the following sequence; open the top cover all the way until it stops at hinges, unlock the

printhead assembly by pushing the printhead release lever and open it towards the left side of the

printer all the way until it stops and stands upright and at the same time unlock the transparent

sensor guide by pushing the transparent sensor guide release lever and open it towards the left side

of the printer all the way until it stops.

2 When the media being used is a black mark tag or label, adjust the lower reflective sensor only (align

the R mark) to the black marks on the tag or label. Then lower the transparent sensor guide fully to

the end and push it to lock and route the media over the platen out to the front of the printer.

Sensor position mark

Reflective sensor

(light-receiving device)

Light-emitting device