Chapter 5 Control Block and Status Block|ScrEdit Software User Manual

5-6 Revision Apr. 30th, 2007, 2007PDD23000002

Bit Number

Function

6 Clear flag of history buffer 7

7 Clear flag of history buffer 8

8 Clear flag of history buffer 9

9 Clear flag of history buffer 10

10 Clear flag of history buffer 11

11 Clear flag of history buffer 12

12~15 Reserved

Clear Flag of History Buffer

HMI history buffer (Fig. 5.1.2) can be cleared by the external controller, i.e. PLC. Once the control flag

is triggered to ON (Bit 0 ~ Bit 11 is set to ON), it will clear HMI history buffer ONCE. This flag needs be

set to OFF and then ON if the user wants to trigger again.

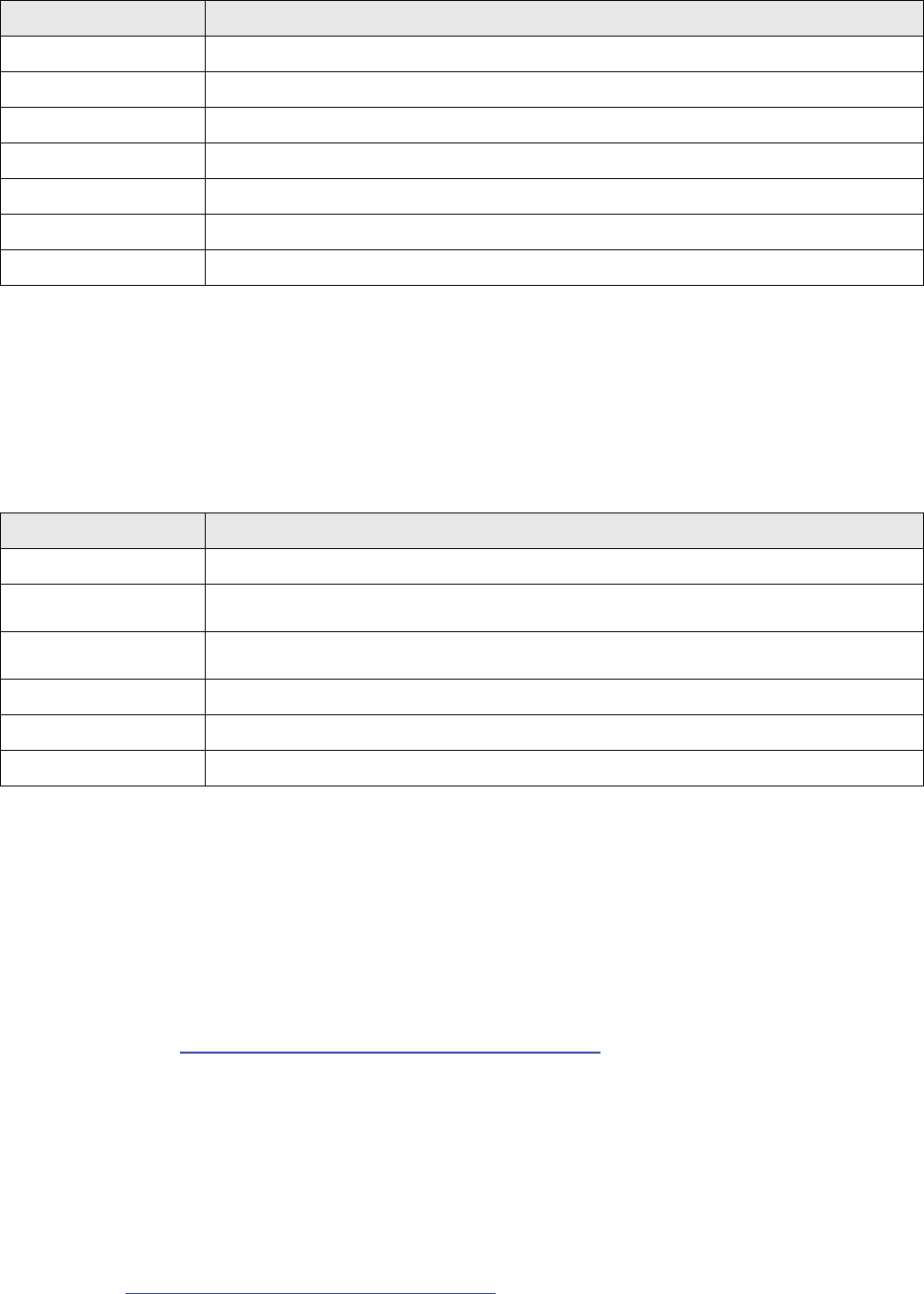

Recipe Control Register (RECR)

Bit Number

Function

0 Recipe number change

1

Read recipe (PLC

→

HMI)

2

Write recipe (HMI

→

PLC)

3 Recipe group number change

4~7 Reserved

8~15 Designate change recipe group number

Control Flag for Changing Recipe Number

There are two kinds of methods for changing and calling recipe number. One method is to use HMI

internal register, RCPNO directly. RCPNO is the internal system register used for designating recipe

number. The other method is to use Recipe Control Register (RECR) (Dn+5). When the user wants to

change HMI recipe number, i.e. RCPNO value through control block settings, first, it needs to write

recipe number (N) into Designated Recipe Number Register (RBIR) (Dn+6, please refer to the

explanation of Register for Designating Recipe Number (RBIR)

) and use this control flag to trigger Bit 0

of Dn+5 to be ON. After setting, RCPNO will be changed to N automatically. This flag needs be set to

OFF and then ON if the user wants to trigger again.

Control Flag for Reading Recipe

The user can change the recipe value of PLC by triggering this control flag (Bit 1 is set to ON). Before

reading a recipe from PLC, the user should designate the recipe number (N) first (Please refer to the

section “Control Flag for Changing Recipe Number

”). Then, trigger this control flag to ON (Bit 1 is set to

ON). After setting, the recipe will be read from PLC and stored in designating area of HMI. This flag

needs be set to OFF and then ON if the user wants to trigger again.