37

FVR-C9S-7UX

16. Electromagnetic Compatibility (EMC)

1. General

In accordance with the provisions described

in the European Commission Guidelines

Document on Council Directive 89/336/EEC,

Fuji Electric Co., Ltd. has chosen to classify

the FVR-C9S-7UX range of drives as “Com-

plex Components”. Classification as “Com-

plex Components” allows a product to be

treated as “apparatus”, and thus permits

compliance with the essential requirements

of the EMC Directive to be demonstrated to

both an integrator of FVR drives and to his

customer or the installer user. FVR drives up

to 2 Hp are supplied “CE-marked”, signifying

compliance with EC Directive 89/336/EEC

when fitted with specified filter units installed

and earthed in accordance with this sheet.

This specification requires the following

performance criteria to be met.

Immunity : EN50082-2

Emissions : EN50081-1

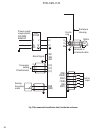

2. RFI Filters

It is strongly recommended that the appro-

priate FVR input filter is used, as shown in

the followings, to limit RF current flowing

into the main supply circuit. Without an input

filter a FVR installation may not meet statu-

tory requirement. FVR drives contain high

power semi-conductor devices which are

switched at high speeds to synthesis a near-

sinusoidal current waveform across the

frequency range of the output. Rapidly-

changing voltages and currents will generate

some degree of electromagnetic emission.

Emissions will be predominantly conducted

through the motor and the mains supply

cables, although some radiated emissions

will be detected in close proximity to the

drive system. It is essential that precautions

are taken both at the design stage and at the

time of installation to prevent radio fre-

quency interference (RFI) from the drive

system affecting sensitive equipment in

close proximity.

3. Recommended Installation Instructions

It is necessary that to conform to the EMC

Directive, these instructions must be fol-

lowed. Follow the usual safety procedures

when working with electrical equipment. All

electrical connections to the filter, drive and

motor must be made by a qualified electrical

technician.

1) Check the filter rating label to ensure that

the current, voltage rating and part number

are correct.

2) The back panel of the wiring cabinet of

board should be prepared for the mounting

dimensions of the filter. Care should be

taken to remove any paint etc. from the

mounting holes and face area around the

hole of the panel. This will ensure the best

possible earthing of the filter.

3) The filter should then be securely

mounted in position, and the drive mounted

to the front of the filter with the screws

provided.

4) Connect the incoming mains supply to the

filter terminals marked “LINE” and earth any

cables to the earth stud provided. And fit the

Input Ferrite Ring (if required two ferrite

rings, refer to table 1), then connect the filter

terminals marked “LOAD” to the mains input

of the drive using short length of appropriate

gauge wire.

5) Fit the Output Ferrite Ring as close to the

drive as possible and connect the motor.

Armored or screened cable should be used

with the 3 phase conductors only passing

twice through the center of the Output Fer-

rite Ring. The earth conductor should be

securely earthed at both drive and motor

ends. The screen should be connected to

enclosure.