5-47 To check the output stability, proceed as

follows:

a.

Connect test setup shown

in Figure 5-5.

b. Turn CURRENT controls

fully

clockwise

and adjust VOLTAGE controls for 40Vdc output.

c. Allow 30 minutes warm-up then record

the differential voltmeter indication.

d.

Mter

8 hours, differential voltmeter

should

change by less than

45mV

from indication

recorded in Step c.

5-48 TROUBLESHOOTING

5-49 Before attempting to troubleshoot this in-

strument, ensure that the

fault

is with the instru-

ment and not with an associated circuit. The per-

formance test (Paragraph 5-10) enables this to be

determined without having to remove the instru-

ment from the cabinet.

5-50 A

gcod understanding of the principles of

operation is a helpful aid

in troubleshooting, and

it is recommended that the reader review Section

IV of the

manua~

before attempting to troubleshoot

the unit in detail. Once the principles of opera-

tion are understood, refer to the overall trouble-

shooting procedures in Paragraph 5-53 to

locate

the symptom and probable cause.

5-51 The schematic diagram at the rear of the

manual (Figure 7-1) contains normal voltage

read-

TM 11-6625-2965-14&P

ings taken at various points within the circuits.

These voltages are positioned adjacent to the ap-

plicable test points (identified by encircled num-

bers). Component and test point designations are

marked directly on the main printed wiring board.

5-52

If

a defective component is located, replace

it and re-conduct the performance test. When a

component is replaced, refer to the repair and re-

placements and adjustment and calibration para-

graphs in this section.

5-53 OVERALL TROUBLESHOOTING PROCEDURE

5-54 To locate the cause of trouble follow Steps

1, 2, and 3 in sequence.

(1) Check for obvious troubles such as

open fuse, defective power cord, input power fail-

ure, or defective voltage or current meter. Next

remove the top cover (held by four retaining

screws) and inspect for open connections, char-

red components, etc. If the trouble source cannot

be detected by visual inspection, proceed with

Step 2.

(2) In almost

all

cases, the trouble can be

caused by improper dc bias or reference voltages;

thus, it is a good practice to check voltages in

Table 5-2, before proceeding with Step 3.

(3) Disconnect the

load and examine Table

5-3 to determine your symptom and probable cause.

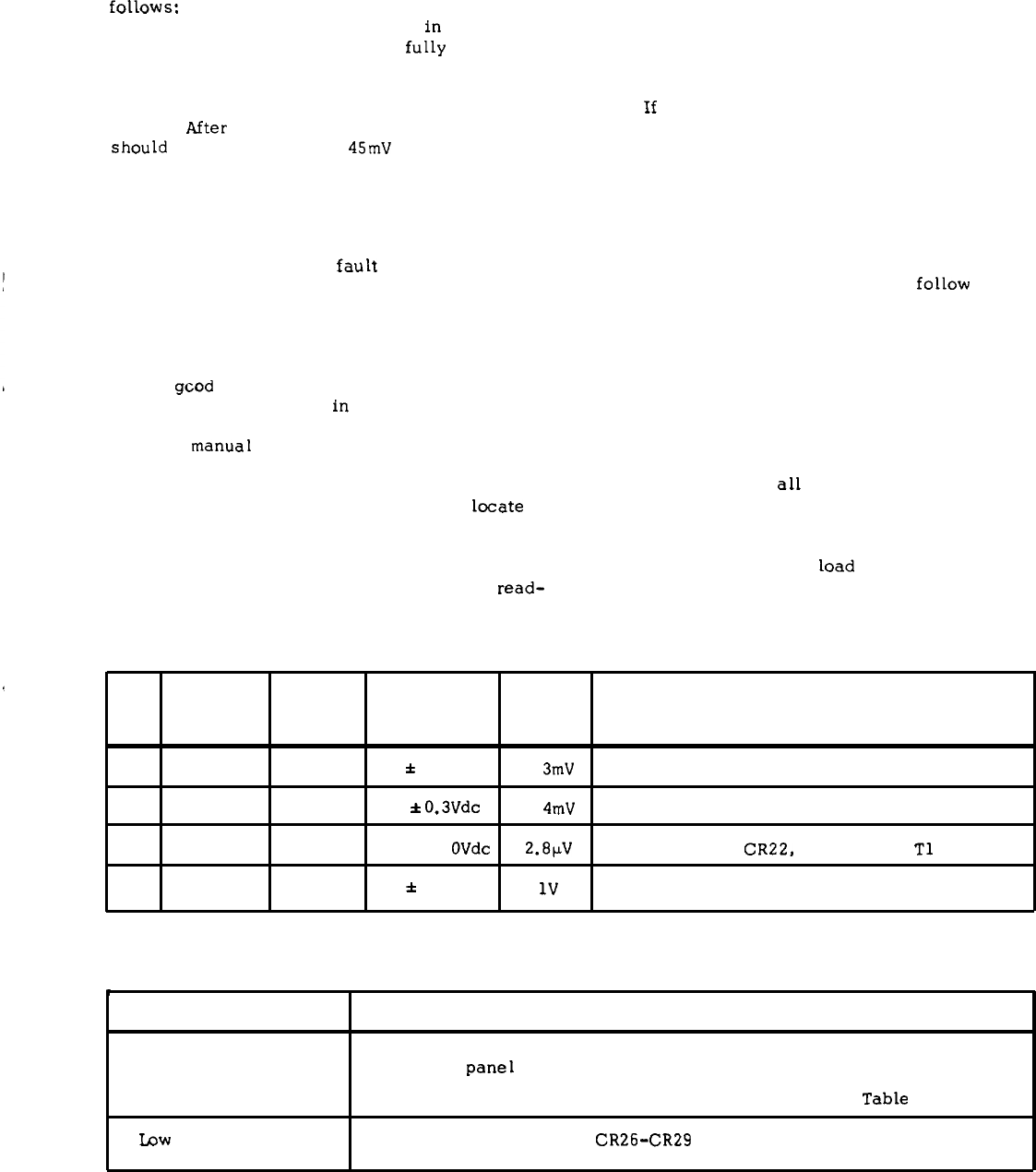

Table 5-2. Reference Circuit Troubleshooting

METER METER

NORMAL

NORMAL

STEP

COMMON

POSITIVE

INDICATION

RIPPLE

IF INDICATION ABNORMAL, TAKE THIS ACTION

(P-P)

1

+s

33

6.2

*

0.3Vdc

.

3mV

Check 12.4 Volt bias or VR1 (See next paragraph)

2

31

+s

6.2

+

0.3Vdc

.

4mV

Check 12.4 Volt bias or VR2 (See next paragraph)

3

+s

37

12.4 *1.

OVdc

2.8KV

Check Q8, Q9, CR22, CR23, C1O,

T1

4

38

41

7.5 * .7Vdc

lV Check C12, CR8, CR24, CR25

Table 5-3.

Overall Trouble shooting

v

SYMPTOM

CHECKS AND PROBABLE CAUSES

High output voltage

a. Front

panel

meter defective.

b. Series regulator feedback loop defective. Refer to

Table 5-4.

Low

output voltage

a. Fuses blown (Check

CR26-CR29 or C14 for short).

5-9