Intel

®

5100 MCH Chipset

Intel

®

5100 Memory Controller Hub Chipset for Communications, Embedded, and Storage Applications

TDG July 2008

28 Order Number: 318676-003US

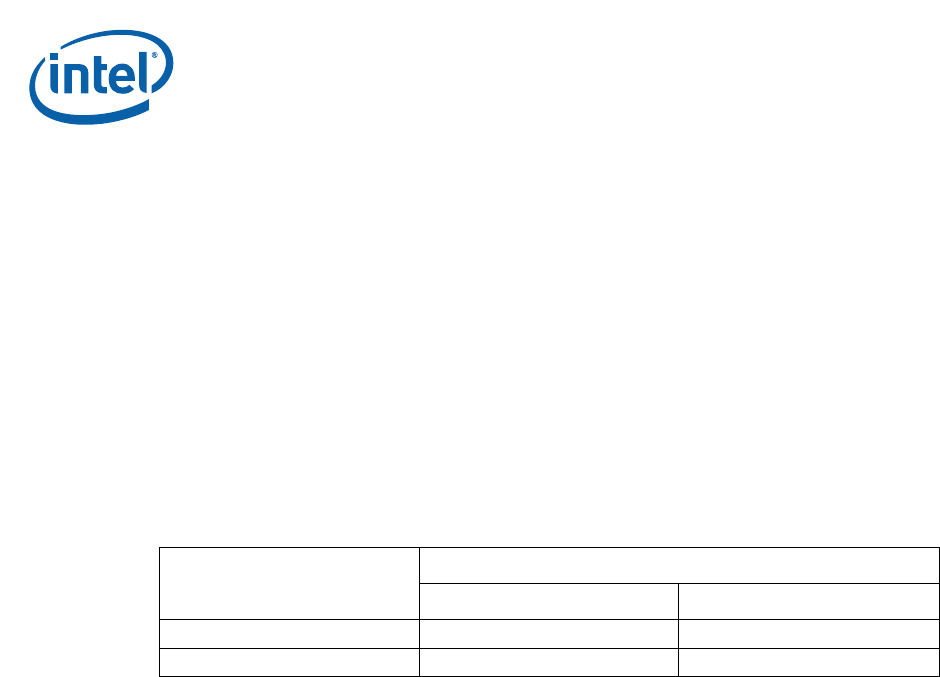

6.1.8.1 Effect of Pressure on TIM Performance

As mechanical pressure increases on the TIM, the thermal resistance of the TIM

decreases. This phenomenon is due to the decrease of the bond line thickness (BLT).

BLT is the final settled thickness of the thermal interface material after installation of

heatsink. The effect of pressure on the thermal resistance of the Honeywell* PCM45F

TIM is shown in Table 6.

Intel provides both End of Line and End of Life TIM thermal resistance values of

Honeywell* PCM45F. End of Line and End of Life TIM thermal resistance values are

obtained through measurement on a Test Vehicle similar to the Intel

®

5000 Series

Chipset’s physical attributes using an extruded aluminum heatsink. The End of Line

value represents the TIM performance post heatsink assembly, while the End of Life

value is the predicted TIM performance when the product and TIM reaches the end of

its life. The heatsink clip provides enough pressure for the TIM to achieve an End of

Line thermal resistance of 0.345 (°C × inches

2

)/W and End of Life thermal resistance of

0.459 (°C × inches

2

)/W.

6.1.9 Heatsink Clip

The reference solution uses a wire clip with hooked ends. The hooks attach to wire

anchors to fasten the clip to the board. See Appendix A for a mechanical drawing of the

clip.

6.1.10 Clip Retention Anchors

For Intel

®

5100 MCH Chipset-based platforms that have very limited board space, a

clip retention anchor has been developed to minimize the impact of clip retention on

the board. It is based on a standard three-pin jumper and is soldered to the board like

any common through-hole header. A new anchor design is available with 45 degree

angle bent leads to increase the anchor attach reliability over time. See Appendix B for

the part number and supplier information.

6.1.11 Reliability Guidelines

Each motherboard, heatsink, and attach combination may vary the mechanical loading

of the component. Based on the end user environment, the user should define the

appropriate reliability test criteria and carefully evaluate the completed assembly prior

to use in high volume. Some general recommendations are shown in Table 7.

Table 6. Honeywell* PCM45F TIM Performance as Function of Attach Pressure

Pressure (psi)

Thermal Resistance (°C × inches

2

)/W

End of Line End of Life

2.18 0.319 0.551

4.35 0.345 0.459