207

[Reference]

Reference

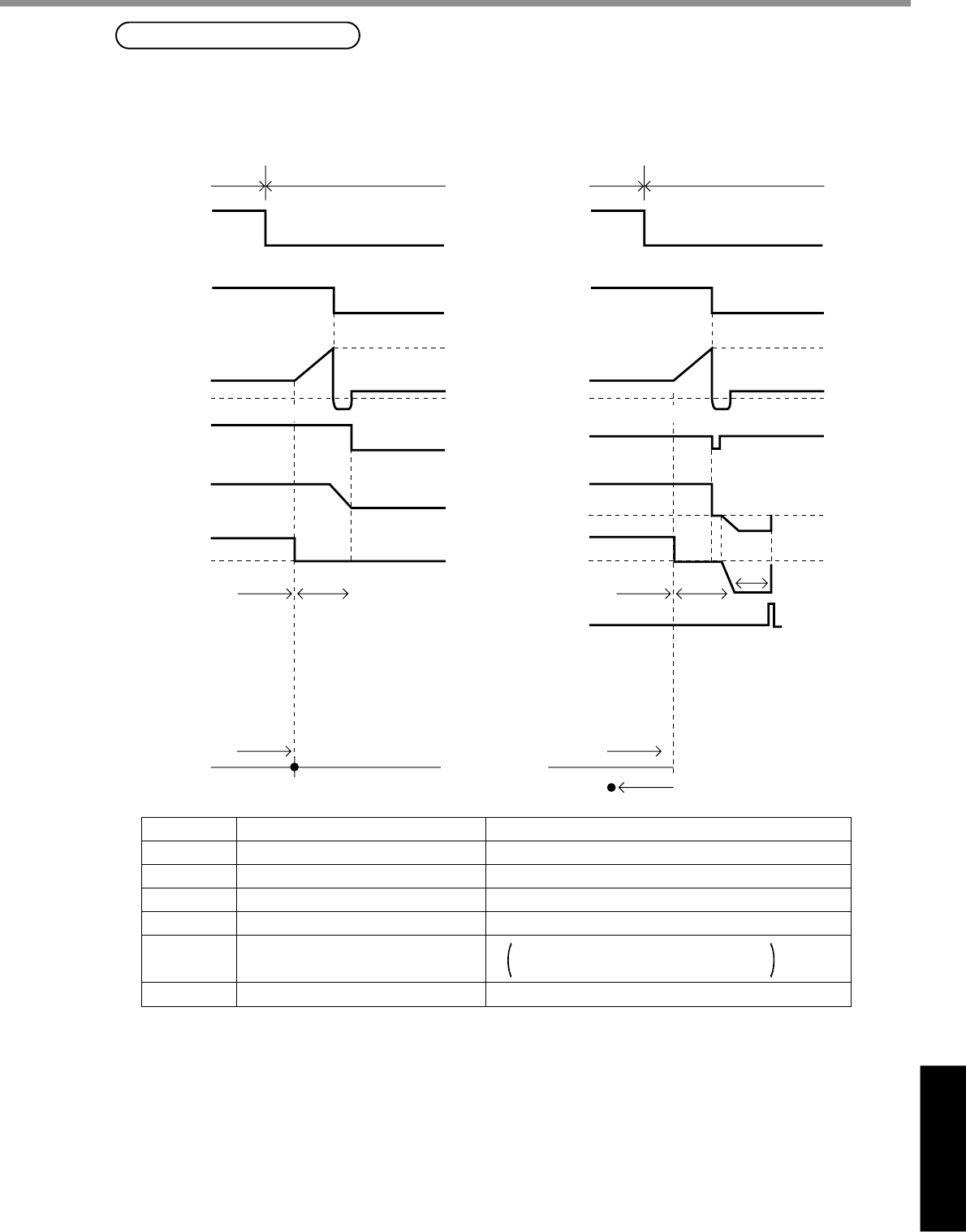

Hit-and-stop Initialization

(1) When you set a point where the motor hits,

as the origin:

1st

Initial Point

Initial Point (3)

2nd Torque Limit 2nd Torque Limit

1st

WARN

(Torque being limited)

Pin 5

(ZEROSPD/TC)

Pin 5

(ZEROSPD/TC)

Torque

Counter

clear

command

50%

Motor

rotation

speed

WARN

(Torque being limited)

When you stop the motor using phase Z

with the hit point as a starting point, and

make it an origin

Torque

Counter

clear

command

Phase Z

Motor

rotation

speed

ON

ON

ON

ON

ON

ON

Parameter No.

70

71

72

73

06

09

<Note>

Set pin 5 "H (OFF)" after hit-and-stop initialization completes.

Name

1st over-speed level set-up

2nd torque limit set-up

2nd position over-deviation set-up

2nd over-speed level set-up

ZEROSPD/TC input selection

Warning output selection

Example of Settings

6000

50 (Set it 100% or less)

1875

(Same as No.1)

6000

2

0 (Torque being limited)

Hitting

Hitting

(1) (2) (1)

(1)

(1)

(2)

(2)

(2)

(3)

When you find it difficult to install a sensor as the surroundings are not good, Hit-and-stop

Initialization can be used.

(2)

Speed zero clamp disabled.

Torque limit switching input enabled.

Hit-and-stop Initialization and Load Pressing Control