C-4 Paper Specifications

OG L 0 1

Paper Composition

Use paper made from 100% chemical wood pulp. Paper that contains mechanically-

pulped wood or cotton is not recommended due to natural impurities, such as CaCO

3

,

that can contaminate the surface of the photoconductor, thereby decreasing the life of

the photoconductor and/or the fuser.

Do not use coated paper containing material that will melt, vaporize, offset, discolor,

or release hazardous emissions when exposed to high temperatures.

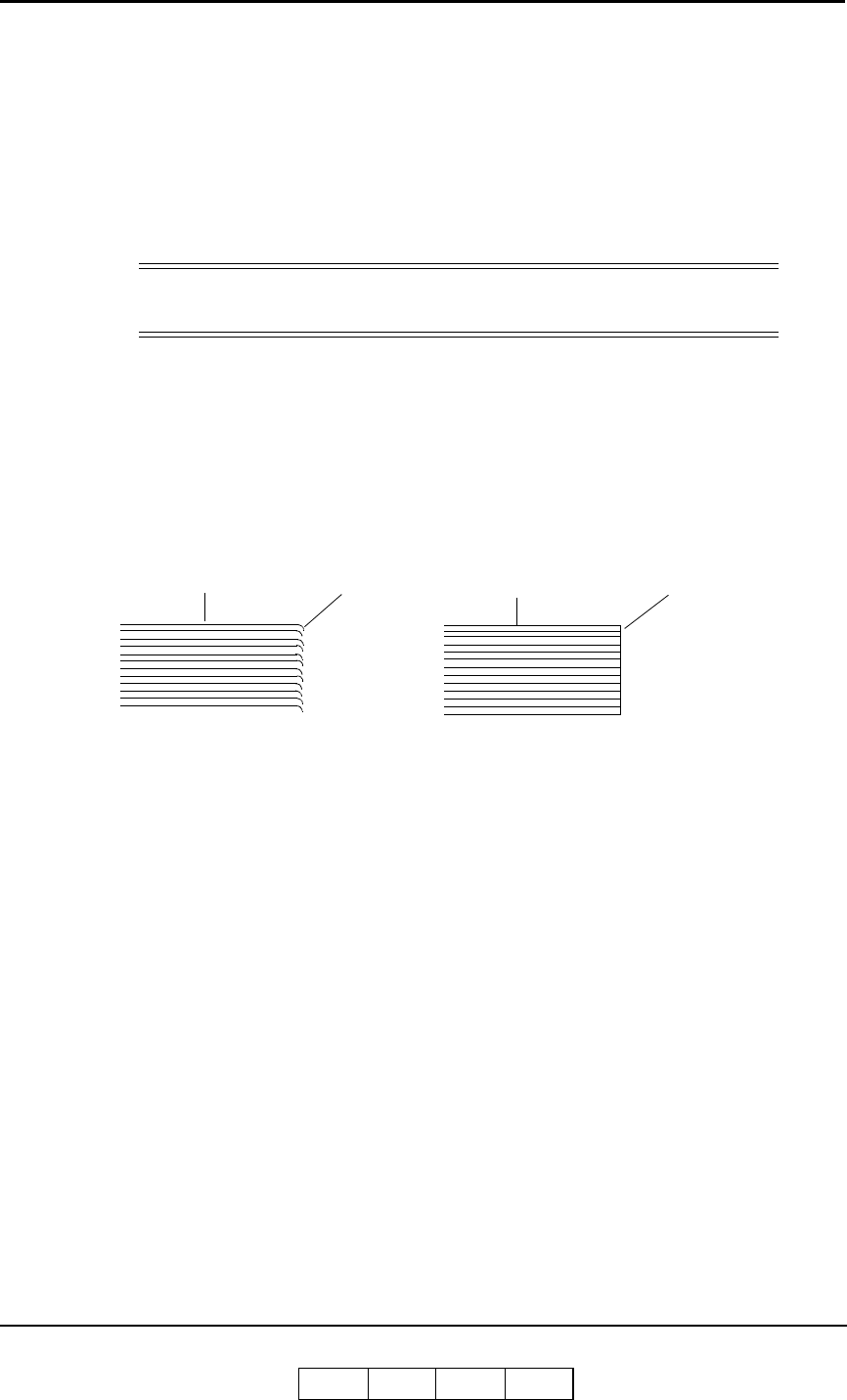

Paper Cut

Paper cut is another significant factor affecting printer performance. The cut sheet is

produced by cutting a larger stack of paper. If a dull cutter is used, the paper will have

ragged edges, or what is called a “burr.” This burr can cause such problems as paper

jam, multiple feed, and large amounts of paper dust. Refer to “Paper Specifications” on

page C-2 for additional information.

Paper Friction

The frictional properties of paper are very important for reliable paper picking.

Improper friction properties can cause poor pick up and multi-sheet feeding. High

quality xerographic paper has uniform friction. Refer to “Paper Specifications” on

page C-2 for additional information.

CAUTION!

Do not use paper that contains CaCO

3

as it can drastically reduce fuser life.

Dull Cut Paper Sharp CutPaper