Paper Specifications C-5

OG L 0 1

Paper Smoothness

Paper smoothness affects print quality and paper handling. Paper should not have a

rough texture. A rough texture provides poor toner adhesion, particularly in “black fill”

areas. Neither should the paper be too smooth, as this can also affect toner adhesion.

Paper that is too smooth has inadequate friction and can cause paper handling

difficulties. Do not use paper with embossed or raised surfaces. Spotty printing and

misfeeding may occur. Refer to “Paper Specifications” on page C-2 for additional

information.

Paper Fusing

Paper used in the printer must withstand the effects of the fusing process. It should not

melt, discolor, vaporize, offset, or delaminate at the following temperature for 1/2

second: 205

o

C (401

o

F).

Moisture

Moisture affects both paper curl and print quality. Excessive moisture can cause the

following things:

Wavy edges

Tight edges

Paper curl

Faded printing

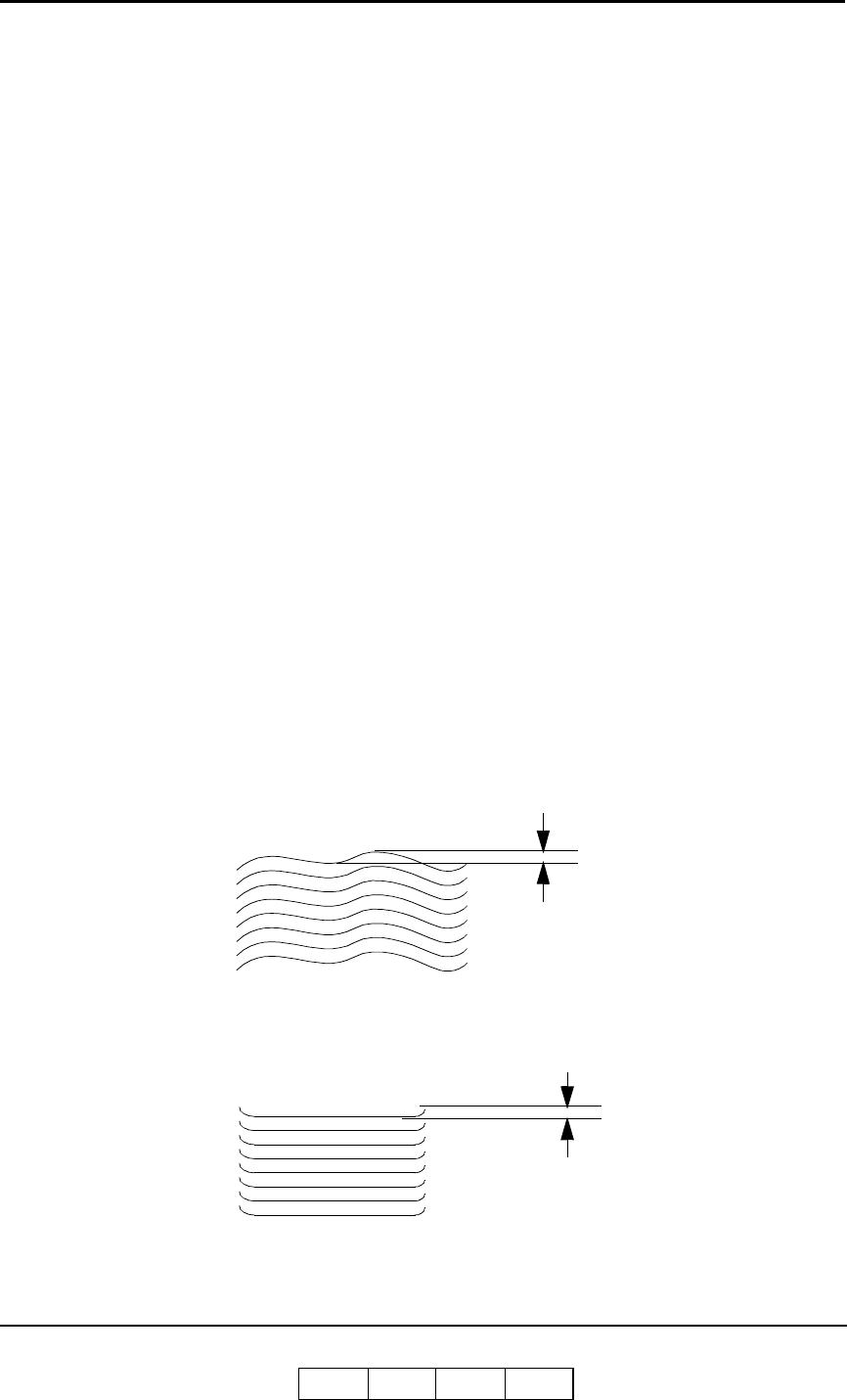

An increase in humidity can cause paper to develop wavy edges. This occurs because

the edges absorb moisture while the rest of the ream remains unaffected. This can cause

paper skewing and inability to pick paper. Wave is measured as shown below. Do not

use paper with a wave of more than 2 mm.

If there is a decrease in humidity the edges can lose moisture. This causes them to

contract resulting in tight edges. Tight edges are measured as shown below. Do not use

paper with tight edges of more than 6 mm.

Less than 2 mm

Less than 6 mm