Unit 4: Operation

SATO XL400-410e Operator Manual PN 9001135A Page 4-28

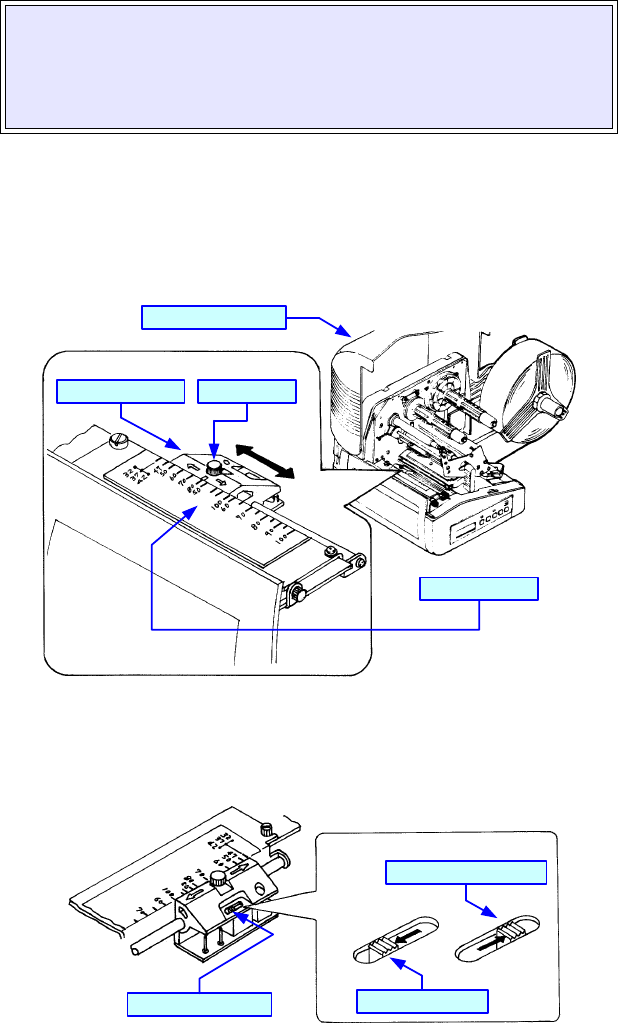

CUTTER SENSOR POSITIONING

The cutter assembly has dual adjustable sensors and is designed to permit lateral movement of

the sensor assembly to accomdate multiple media types. To position the sensor, loosen its set

screw and move the sensor assembly along the incremented scale to the correct position so that

it aligns with its reference mark on the media and then retighten the set screw. Then select which

of the dual sensors is also applicable to the media of use.

If the media was incorrectly positioned following sensor adjustment, press the FEED key to

reposition. If the power was removed while printing, the media may be incorrectly positioned

when power is restored and may print several blank tags. Press the START/STOP key to pause

the print job and switch off power. When power is restored, the printer will correctly position the

tags.

Figure 4-14a, Cutter Sensor Positioning

Figure 4-14b, Cutter Sensor Positioning

NOTE: In order for the sensor to function properly, it must be

correctly positioned and the switch properly set for the applicable

media. If the cutter assembly still does not operate correctly, the

sensor’s sensitivity may require adjustment. Refer to the

Maintenance Unit for instructions on sensor sensitivity adjustment.

Sensor Scale

Set Screw

Top Housing Cover

Sensor Assembly

Sensor Switch

R-Corner Media

All Other Media Types