Unit 6: Maintenance

SATO XL400-410e Operator Manual PN 9001135A Page 6-6

ADJUSTMENT PROCEDURES

To maintain optimum performance and print quality, periodically mechanical adjustments will

have to be made. These adjustments are typically required following the replacment of a

component.

Other adjustments may be required due to variations in media size or quality and due to different

print image denseness. Instructions relative to those conditions are not covered here. Refer to

the Installation and Operation units for those relative instructions.

This chapter provides instructions on the performance of those activities that are mechanical in

nature and are responsive to maintenance activities. The table below provides common print

defects and their relative cause.

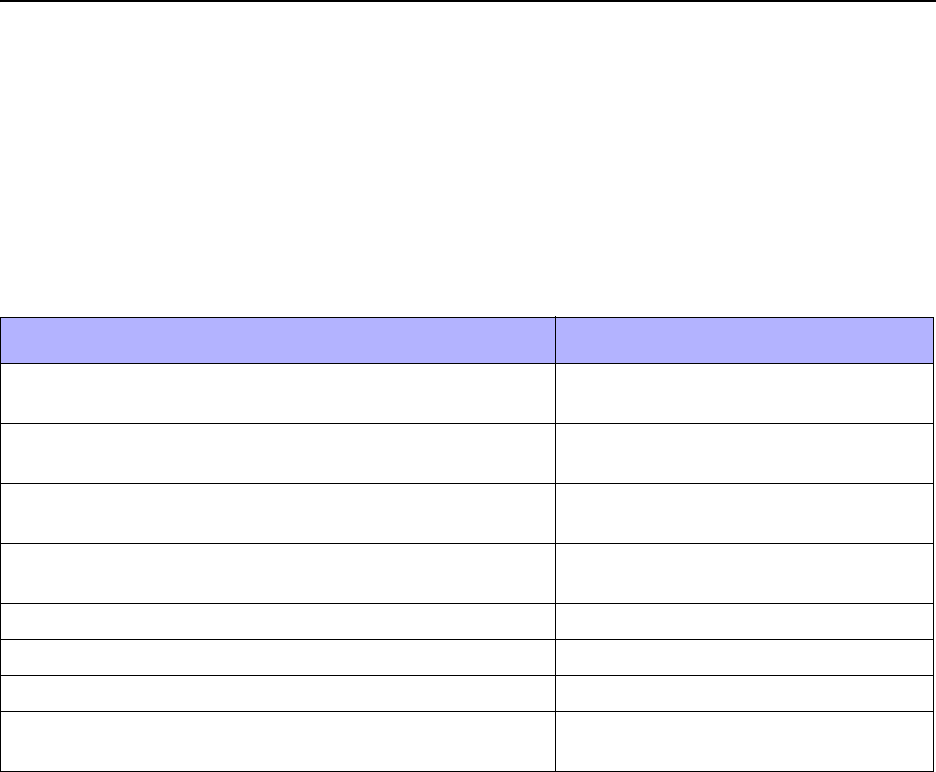

PRINT DEFECTS RELATIVE PROCEDURE

Print becomes lighter or darker from one side to the other.

This condition is repetitive from label to label.

Print Head Balance Adjustment

Voids in the overall print image that is repetitive from label to

label.

Print Darkness Adjustment

A visible path on the label where print image is missing. The

path will change somewhat from label to label.

Print Position Alignment

Platen Roller Adjustment

The scales at the lower left and right sides are not equal

distances from the labels lower edge.

Print Position Alignment

The lines are not sharp. Print Darkness Adjustment

The image is too light or dark. Print Darkness Adjustment

Bar code label has a sharp line where print is missing. Print Darkness Adjustment

The printed position is too far in one direction or another. Print Position Adjustment

Offset Label Stop Position