Unit 6: Maintenance

SATO XL400-410e Operator Manual PN 9001135A Page 6-10

PRESSURE ROLLER BALANCE

The pressure roller works in conjunction with the feed roller, sandwiching the loaded media

between the two. It is the drive-coupled feed roller that advances the media forward to the platen

roller. The pressure roller is an idle one.

For proper media tracking the two rollers must be perfectly parallel and possess proportionate

pressure from one end to the other. Tracking is the direction the media is inclined to take. When

the rollers are evenly pressured, the media will tavel straight forward without deviating laterally.

When there exists uneven pressure between the two rollers on either end, the media will attempt

to take the route of least resistance. In doing so, will either track to the left or to the right. This

condition is refered to as “wandering”.

Whereas this procedure covers only pressure roller balance, it will most likely be used in

conjunction with the Pressure Roller Alignment procedure that preceded this one.

If the performance of this procedure fails, or adjustment is extreme to remedy the tracking

problem, adjust the two balance set screws evenly at about 5mm and perform the Pressure

Roller Alignment procedure. Return to this procedure for fine tuning as necessity dictates.

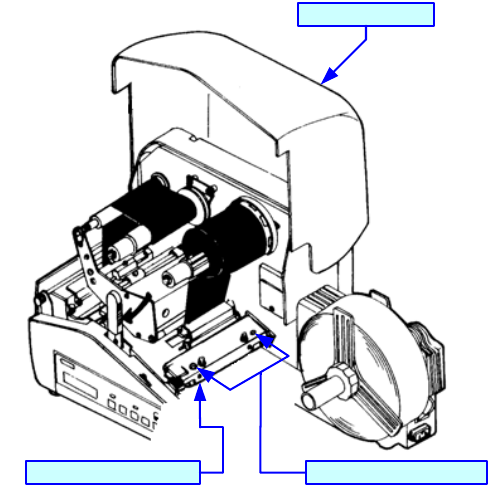

1 Open the top housing cover to access the pressure roller assembly.

2 Begin continuously printing labels.

3 Loosen the lock nut on the end that the media is attempting to track toward.

4 Adjust the adjustment screw while observing the media tracking.

5 Hold the adjustment screw in position and tighten the lock nut upon proper tracking.

Figure 6-8, Pressure Roller Balance

Lock Nut/Adjustment ScrewPressure Roller Assembly

Top Housing Cover