Unit 6: Maintenance

SATO XL400-410e Operator Manual PN 9001135A Page 6-12

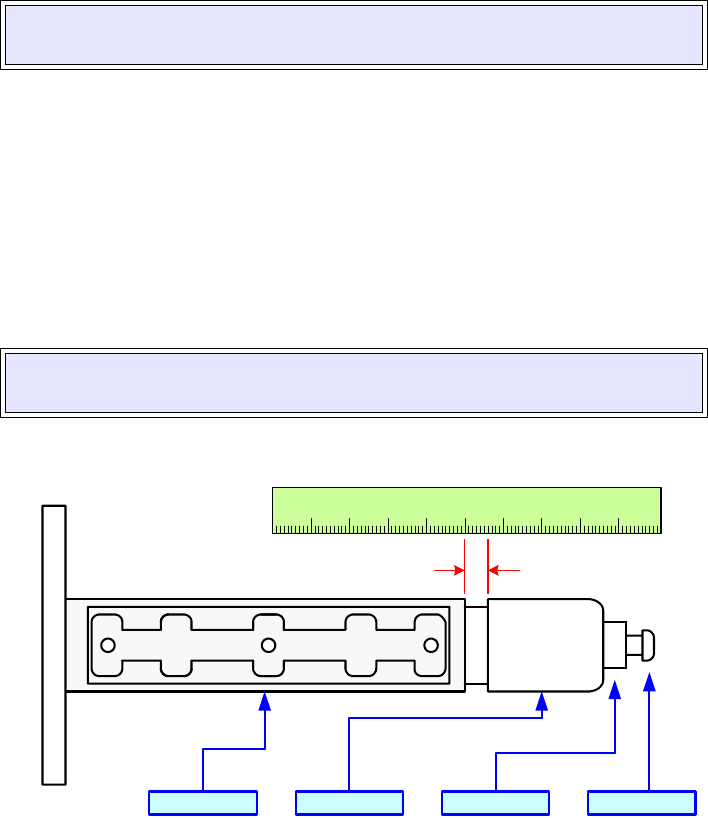

RIBBON SPINDLE TENSIONING

The printer has two ribbon spindles; one to supply ribbon medium from the rear of the printer past

the print head to the spindle closest to the front for the purpose of rewinding the used medium.

The rewind spindle is coupled to the drive train and draws the ribbon medium forward

incrementally with the print media (label/tag) comparable with gearing ratios.

For proper function, the spindles must be individually adjusted with the correct drag. Drag is the

resistance to the advancement of the meduim and is controlled by increasing or decreasing

frictional tension to rotational movement. A torsion spring takes up excess slack in the ribbon

medium during backfeed movement of the print media.

The following procedure explains how to adjust the ribbon spindles without the use of a tension

gage. The procedure is the same for both, however, the tension requirements are different.

To tension adjust the ribbon spindles without the use of a tension gage, perform the following.

1 Open the top housing cover to access the ribbon spindle assemblies.

2 Loosen the set screw while holding the adjustment nut stationary.

3 Turn the adjustment nut in a manner to achieve the required space between the ribbon

boss and the stopper collar. (3.5 to 3.0mm supply spindle, 3.0 to 2.0mm rewind spindle)

4 Hold the adjustment nut in position and secure the set screw.

5 Repeat steps 2 through 4 for the remaining spindle.

Figure 6-10, Ribbon Spindle Tensioning

NOTE: The tension reuirements for the supply spindle is 400-500 grams and

500-700 grams for the rewind spindle should a tension gage be available.

NOTE: A complete revolution of the adjustment nut equals approximately

1mm (100g). Likewise, a half revolution equals .5mm (50g).

Collar Set ScrewAdjustment NutRibbon Boss

Metric Scale