[8] SIMULATION

1. Entering the simulation mode

Perform the following procedure to enter the simulation mode.

Clear key → Interruption key → Shift key → Interruption key → Start

key → Sub code → Start key

2. Cancelling the simulation mode

When the all clear key is pressed, the simulation mode is cancelled.

When the interruption key is pressed, the process is interrupted and

the screen returns to the sub code entering display.

3. List of simulations

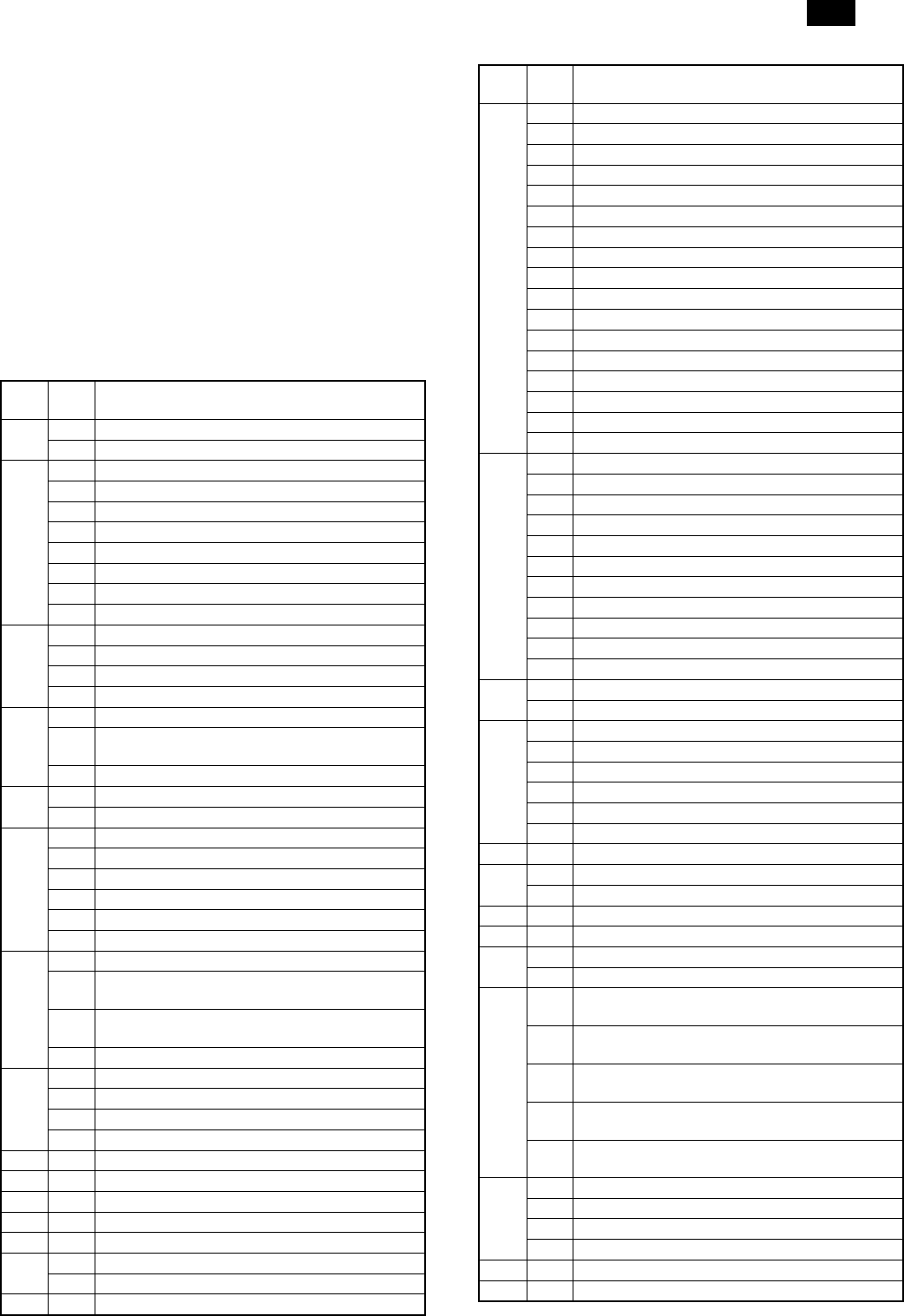

Main

code

Sub

code

Contents

1 1 Mirror unit operation check

2 Optical system sensor operation check

2 1 SPF aging

2 SPF sensor operation check

3 SPF motor forward rotation operation check

4 SPF motor reverse rotation operation check

8 SPF paper feed solenoid operation check

9 SPF reverse solenoid operation check

10 SPF paper exit gate solenoid operation check

11 SPF PS release solenoid operation check

3 2 Shifter job separator sensor operation check

3 Shifter operation check

4 Job separator operation check

10 Job separator home position check

5 1 Operation panel display check

2 Heater lamp lighting check, cooling fan motor

operation check

3 Copy lamp lighting check

6 1 Paper feed solenoid operation check

10 Main cassette semi-circular roller drive

7 1 Aging with JAM with warmup time display

2 Aging without JAM with warmup time display

4 Warmup saving

6 Intermittent aging (with paper)

7 Intermittent aging (without paper)

8 Warmup time display

8 1 Developing bias voltage output check

2 Main charger voltage output check (Grid bias high

mode)

3 Main charger voltage output check (Grid bias low

mode)

6 Transfer charger voltage check

9 1 Duplex motor forward rotation operation check

2 Duplex motor reverse rotation operation check

4 Duplex motor rotation speed adjustment

5 Duplex motor switchback time adjustment

10 Toner motor operation check

14 Trouble (except for U2) cancel

16 U2 trouble cancel

17 PF trouble cancel

20 1 Maintenance counter clear

21 1 Maintenance cycle setting

2 Mini maintenance counter display

22 1 Maintenance counter display

Main

code

Sub

code

Contents

22 2 Maintenance preset value display

3 JAM memory display

4 Total JAM counter display

5 Total counter display

6 Developing counter display

7 Developing preset counter value display

8 SPF counter display

9 Paper feed counter display

12 Drum counter display

14 Flash ROM version display

15 Trouble memory display

16 Duplex print counter display

17 Copy counter display

18 Printer counter display

19 Electronic sort counter display

20 FAX print counter display

21 Scanner counter display

24 1 JAM memory, JAM counter clear

2 Trouble memory clear

4 SPF counter clear

5 Duplex counter clear

6 Paper feed counter clear

7 Drum counter clear

8 Copy counter clear

9 Printer counter clear

10 Electronic sort counter clear

11 FAX print counter clear

13 Scanner counter clear

25 1 Main motor operation check

10 Polygon motor operation check

26 1 Operation switch display

3 Auditor setting

5 Counter mode setting

6 Destination setting

22 Language setting

30 CE mark conformity control setting

30 1 Machine sensor operation check

41 2 OC document sensor adjustment

3 Document sensor light reception level display

42 1 Developer counter clear

43 1 Fusing temperature setting

46 1 Copy density level adjustment

2 FAX density level adjustment

48 1 Main scanning (front/rear) direction magnification

ratio adjustment(Copy/FAX/OC-SPF common)

2 OC mode sub scanning direction magnification

ratio adjustment in copying

5 SPF mode sub scanning direction magnification

ratio adjustment in copying

6 OC mode sub scanning direction magnification

ratio adjustment in FAX

7 SPF mode sub scanning direction magnification

ratio adjustment in FAX

50 1 Copy image lead edge position adjustment

10 Paper off center adjustment

13 OC mode document off center adjustment

16 SPF mode document off center adjustment

51 2 Resist amount adjustment

63 1 Shading data check

AR-160/160 FM/E [8] SIMULATION 12/1/1998

AR-161

8 – 1