6

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

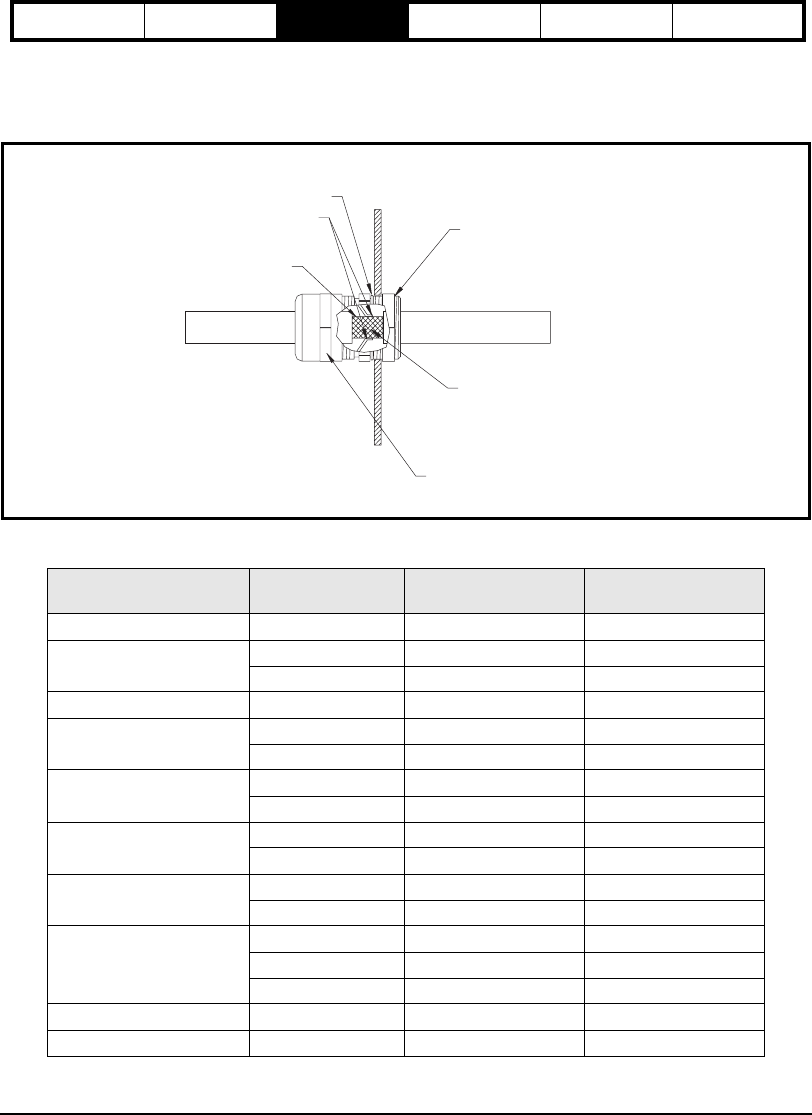

Cable to Enclosure Shielding

Shielded motor, feedback, serial communications and external encoder cables were used for compliance testing and

are necessary to meet the EMC requirements. Each cable shield was grounded at the enclosure wall by the type of

grommet described earlier and shown in the following figure.

Figure 3: Through Wall Shield Grommet

Cable Type Cable Model

Shielded Cable Grommet

Kit Model

Actual Hole Size

Motor Cable, 18 Ga XTMDS CGS-047 0.8125 or 13/16"

Motor Cable, 16 Ga

CMDS CGS-047 0.8125 or 13/16"

4X16SS CGS-047 0.8125 or 13/16"

Motor Cable, 18 Ga XCMDS CGS-047 0.8125 or 13/16"

Motor Cable, 12 Ga

CMMS CGS-069 1.125 or 1 1/8"

4X12SS CGS-069 1.125 or 1 1/8"

Feedback Cable

CFOS CGS-047 0.8125 or 13/16"

MGFS CGS-047 0.8125 or 13/16"

Flex Motor Cable, 16 Ga

CMDF CGS-047 0.8125 or 13/16"

4X16SF CGS-047 0.8125 or 13/16"

Flex Motor Cable, 12 Ga

CMMF CGS-069 1.125 or 1 1/8"

4X12SF CGS-069 1.125 or 1 1/8"

Flex Feedback Cable

CFCF CGS-069 1.125 or 1 1/8"

CFOF CGS-069 1.125 or 1 1/8"

MGFF CGS-069 1.125 or 1 1/8"

External Encoder ENCO CGS-047 0.8125 or 13/16"

AC Power user supplied user supplied user supplied

Cable Jacket

After tightening lock nut and positioning cable

so that Spring Contacts are contacting the

cable shield, tighten Cable Seal Housing.

Remove 1/2 to 1 inch of cable jacket.

The Spring Contacts will make a continuous

electrical path from the shield of the cable to

equipment ground.

When Lock Nut is tightened to inside of

enclosure, lock nut will cut through varnished,

anodized, and powder coated finishes.

Tighten lock nut so it cuts through the

finish and into housing.

Outside Enclosure

Cable Shielding

Spring Contacts

O-Ring seals against outside of enclosure

to meet IP68 (comparable to NEMA 6)

Inside Enclosure