Pressure Systems, Inc. NetScanner™ System (9016, 9021, & 9022) User’s Manual

www.PressureSystems.com

2 - 7

2.3.5

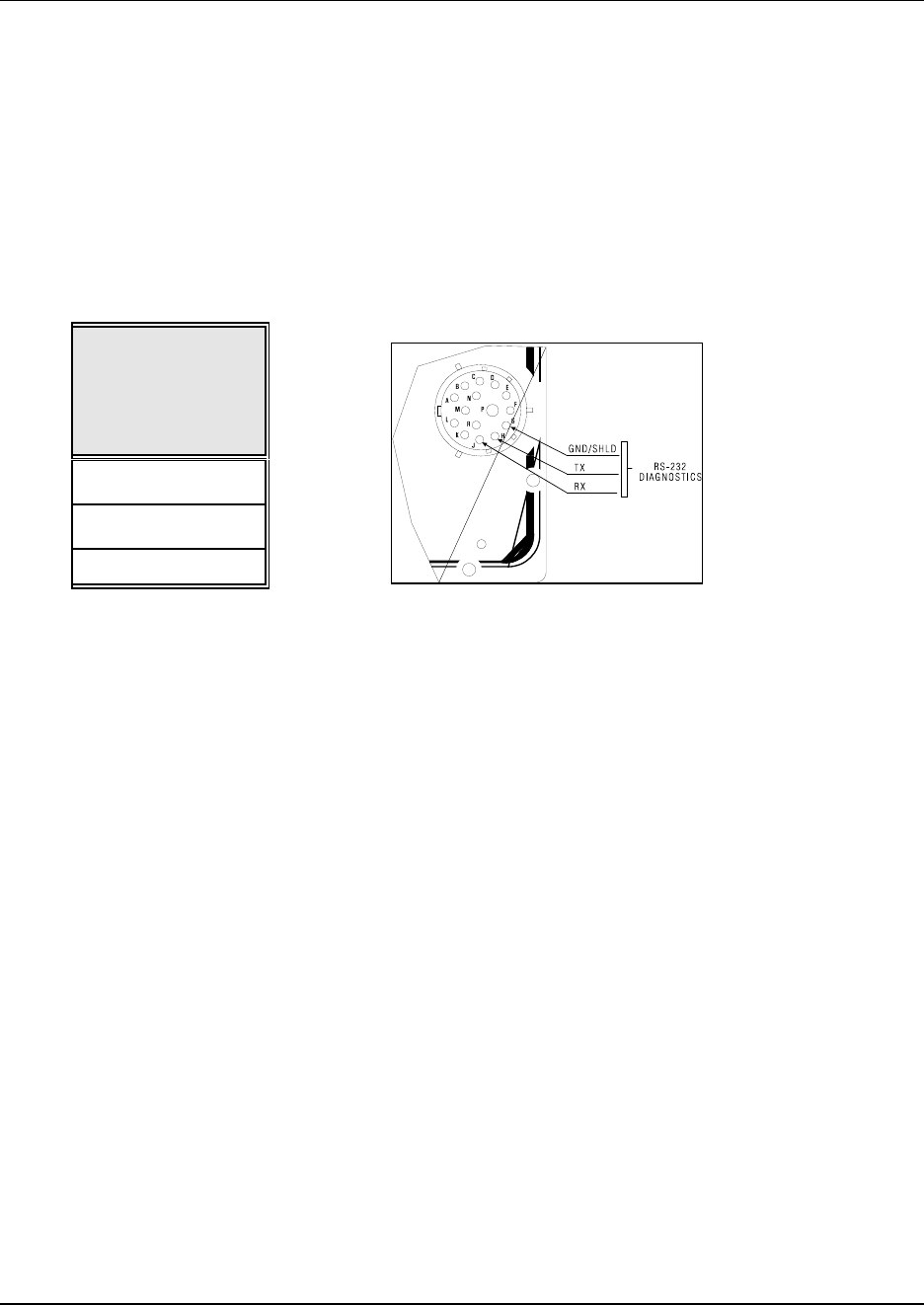

Diagnostic Port Hookup

Each NetScanner

™

System module contains a Diagnostic Port that supports diagnostic and

operational functions. The Diagnostic Port has only a simple RS-232 asynchronous serial interface.

The connections are made via certain pins of its common circular connector. Cable connection

should be made according to Table 2.1.

Table 2.1

Diagnostic Port Wiring

NetScanner

™

System

Diagnostic Port

Connector

GND

Tx

Rx

The RS-232 interface is capable of supporting simple asynchronous communications with fixed

parameters of 9600 baud, no parity, 8 data bits, and 1 stop bit. Only communication cable lengths

less than 30 feet (10 m) are recommended.

The 9016, 9021 and 9022 use the diagnostic interface for optional configuration and diagnostic

purposes only. The diagnostic port functions on the 9016, 9021, and 9022 are generally not required

by the end user. Standard cables for these modules do not include diagnostic port connections.

2.3.6 Pressure Connections

All pneumatic connections to Model 9016 are found on the instrument top panel. The function of

each input port is clearly engraved or printed next to each input. Connections are through bulge

tubing, compression fittings or special user-supplied fittings on the tubing plate. All pneumatic

inputs to these modules should contain dry, non-corrosive gas only. For Model 9021/9022, all

pneumatic or hydraulic connections are to the individual 9400, 9401, or 9402 (or third party) all-

media transducers mounted externally from the module itself.

All 9016 standard Intelligent Pressure Scanners are supplied with the purge/leak check calibration

manifold. Through software commands, this valve may be placed in one of four positions; RUN,

CAL, PURGE, or LEAK-CHARGE. Pneumatic input requirements for these four operating

positions are described in the following sections.