640t – Installation and Operating Instructions

Page 6-2

lo a d i n g fi l m

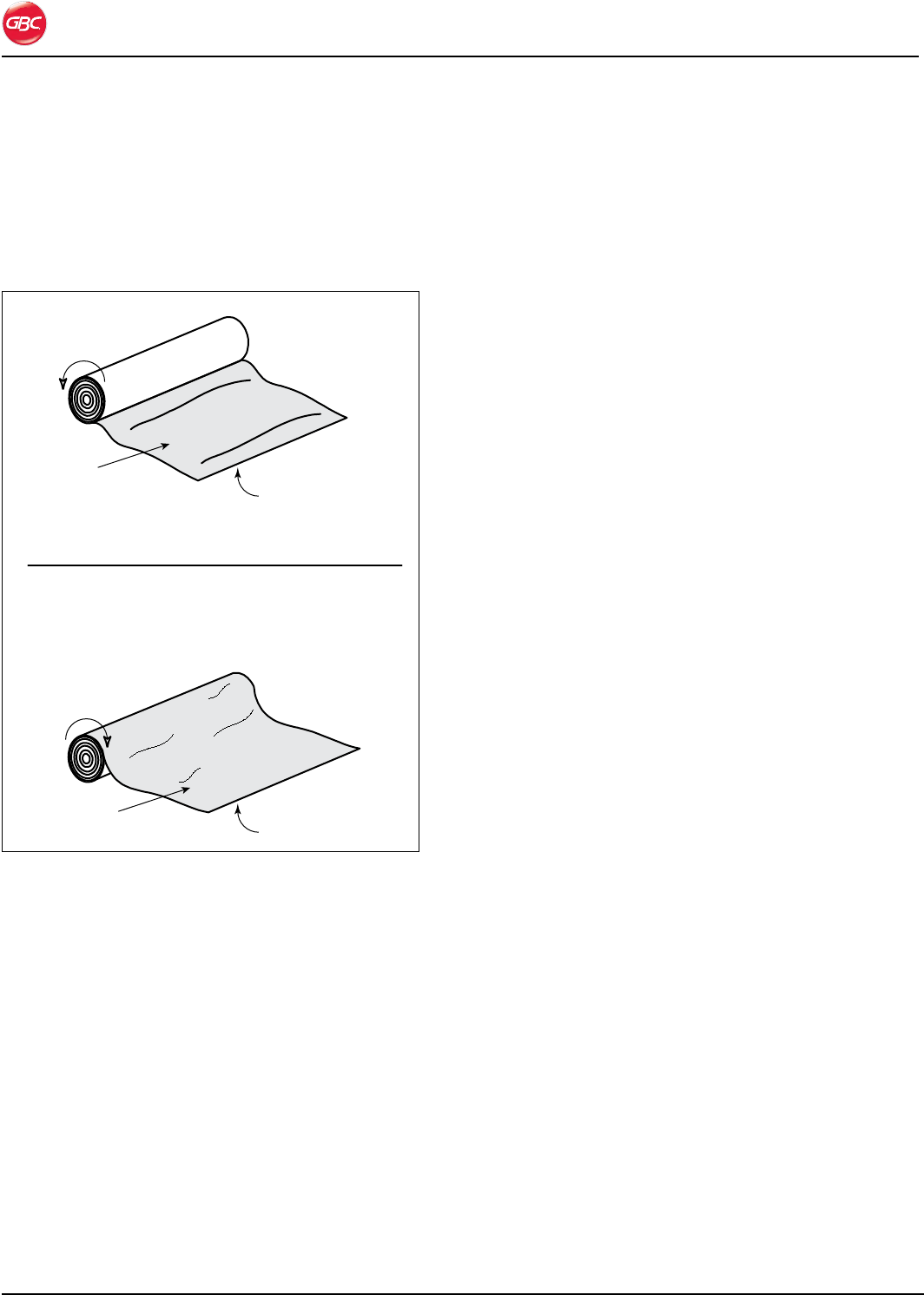

The 640t laminator runs poly-in and

poly-out pressure sensitive adhesive (PSA) lms.

Poly-in means the adhesive side of the lm is on the

inside of the lm roll. Poly-out means the adhesive is

on the outside of the lm roll.

Adhesive surface

Adhesive surface

Polyester surface

Polyester surface

Poly-in

Poly-out

Fig. 6-3. Poly-in and Poly-out Films.

The machine can perform four functions:

Decaling (laminating and applying an adhesive •

to the back of the item).

Mounting, using one film.•

Mounting, using no film.•

Roll-to-roll over-lamination.•

IMPORTANT: The top and bottom rolls of laminating

lm must be the same width.

Always change the top and bottom supply rolls at the

same time.

The lm will wrap around the rollers if:

One or both rolls of film are allowed to run •

completely off its core.

Only one roll is used.•

Different widths of rolls are loaded together. •

Either roll is loaded with the adhesive side •

against a roller.

There are two methods of loading lm.

Using a threading card.•

Tacking new film to existing film.•

These are described in “Threading Film with a

Threading Card” on page 6-5 and “Loading Film by

Tacking New Film to Existing Film” on page 6-7. Prior

to loading lm, the print clamp and feed table need

to be removed.