Page 6-9

640t – Installation and Operating Instructions

After the board has cleared the rollers, release 10.

the foot switch or press STOP.

mo u n t i n g

ti p s fo r th r e a d i n g pr e s s u r e

s

e n s i t i v e ad h e s i v e (psa) fi l m

Use Kraft paper for one-sided lamination.•

Refer to “Fig. 6-14. Configurations for Poly-in •

and Poly-out Films.”

for the proper film

configuration.

Whenever possible, pull the remaining web •

of film out the front of the laminator after the

finished item has been removed.

pr e -co a t i n g Bo a r d s

You may wish to pre-coat mounting boards ahead of

time with PSA mounting lm.

PSA mounting lm

Board

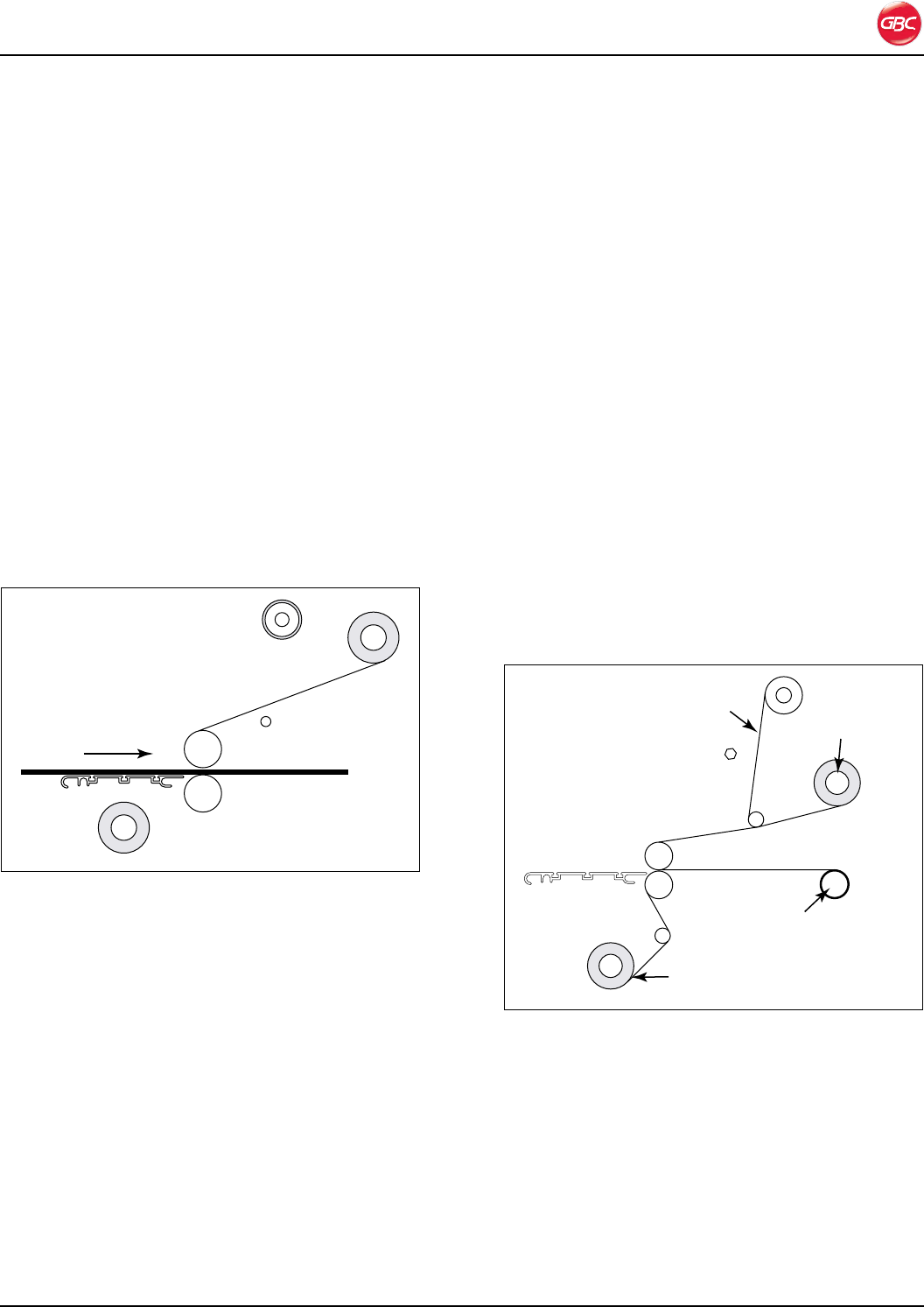

Fig. 6-16. Laminator Ready for Pre-Coating Boards.

To pre-coat boards:

Load the laminator as shown in “Fig. 6-16. 1.

Laminator Ready for Pre-Coating Boards.”

Adjust the roller pressure handle to the proper 2.

mounting setting.

Start a leader board into the rollers. 3.

Press 4. RUN or the foot switch.

Continue feeding one board after another. 5.

Tip: Butt the leading edge of the next board to

the trailing edge of the previous one to ensure an

even application of film.

Press 6. STOP when the last board exits the

machine.

mo u n t i n g on l y

This process requires a decaled item with PSA

mounting adhesive. Refer to the

To run the second

pass instructions

in the

Decaling In Two Passes

section

of this chapter. An alternative method is to use a PSA

pre-treated board on page 6-8, gure 6.15

ro l l-t o -ro l l

Load and thread the lm and media as described in

“Loading Film Onto the Supply Shafts”

and

“Threading

Film with a Threading Card”

. After you have nished

step 14, attach the web to the rear rewind tube with

masking tape.

Fig. 6-17. Laminator Ready for Roll-to-Roll.

Release liner

PSA overlam

Adhesive back media

Rear rewind