640t – Installation and Operating Instructions

Page 6-10

fi l m al i g n m e n t a n d te n s i o n

fi l m al i g n m e n t

The top and bottom supply rolls must be aligned

as closely as possible. Misalignment can cause

adhesives to stick to the rollers.

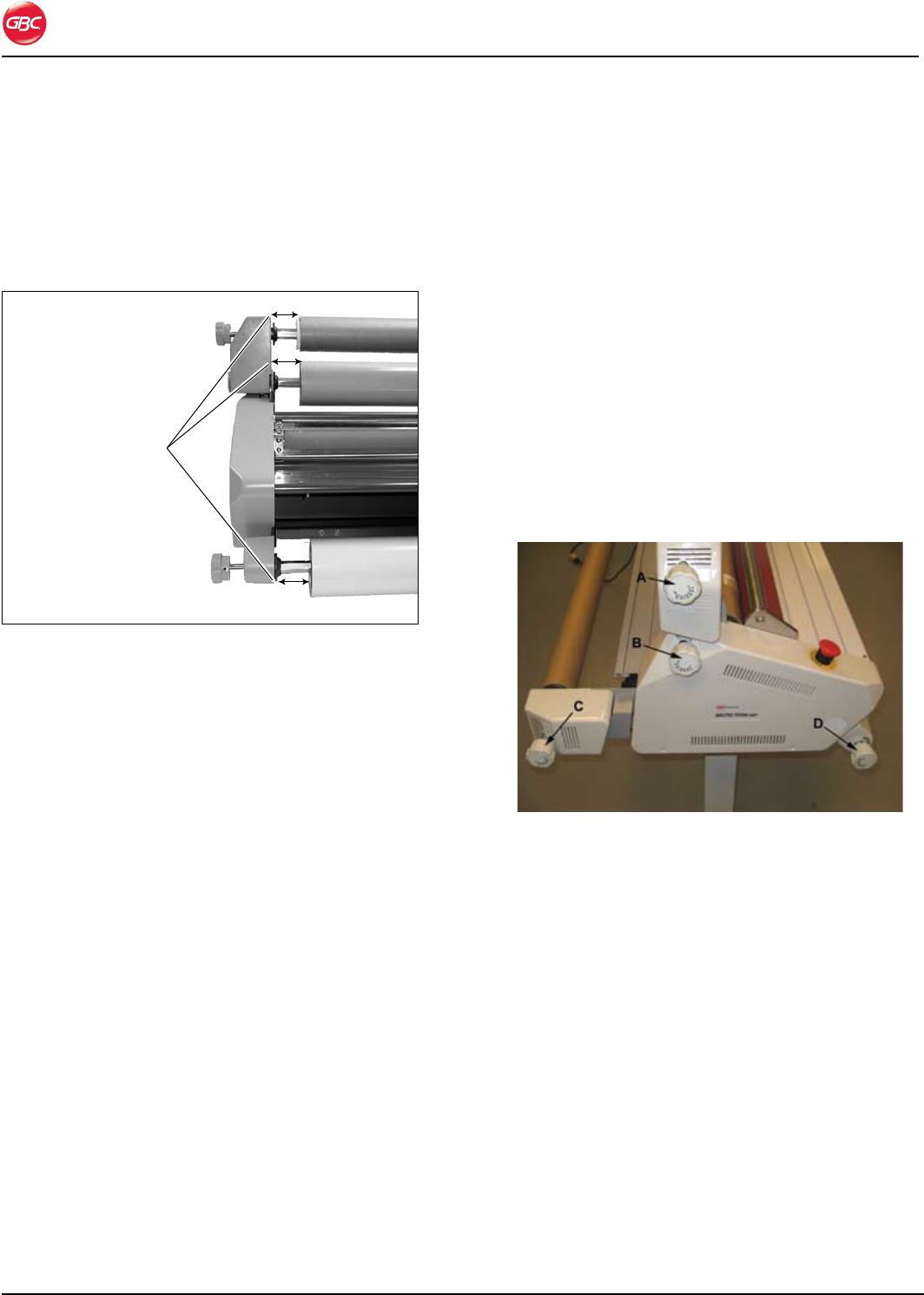

Measure here

Fig. 6-18. Measuring Points on a Typical Laminator..

To align the supply rolls:

Use a ruler to measure the distance between the 1.

left edge of the roll to the side frame.

Measure the distance between the right side of 2.

the roll to the side frame.

Shift the roll side to side to ensure that the two 3.

measurements are equal.

fi l m te n s i o n

Proper lm tension, known as brake tension, is the

minimum amount required to eliminate wrinkles in

the nished item. As the lm roll becomes smaller,

tension increases, thus the adjustment needs

to be loosened. Film tension should be checked

occasionally to ensure that the adjustment is correct.

The lm should be taut with no gaps between the

lm and pressure rollers. A properly adjusted roll of

lm should not require excessive force to turn by

hand. Film tension should be enough to introduce a

minor amount of drag as the lm unrolls. Insufcient

tension causes wrinkles, while too much tension

causes stretching (necking). Uneven tension between

the top and bottom rolls create curl. Too much upper

tension creates upward curl. Too much lower tension

bottom causes downward curl.

Fig. 6-19. Tension Adjustment Knobs and Motor.

The machine is equipped with external tension knobs

located on the left side. Turning the knobs clockwise

increases the tension while counterclockwise

decreases the tension.

Refer to “Tension Controls” on page 5-4.