HX200/HX200L-2000/HX300/HX300L/HX400

3-12

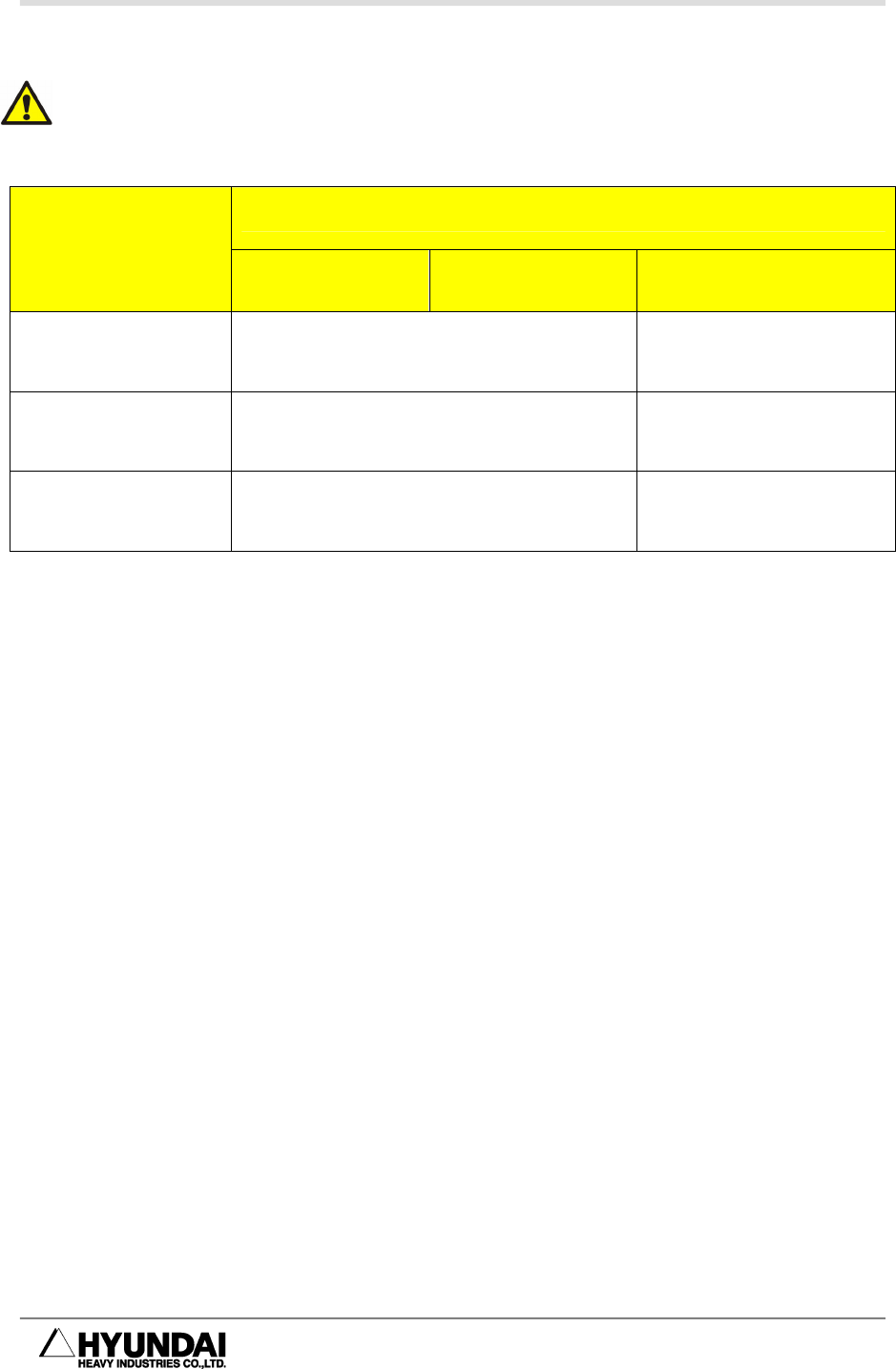

Allowable Moment of Inertia

Table 3-4 Allowable Moment of Inertia

Allowable Load Torque

Robot Model

R2 Axis

Rotation

B Axis Rotation R1 Axis Rotation

HX300/300L 150kg·m²(15.3kgf·m·s²) 30 kg·m²(3.1 kgf·m·s²)

HX400 120 kg·m²(12.2 kgf·m·s²) 50 kg·m²(5.1 kgf·m·s²)

HX200L/200L-2000

117.6 kg·m²(12.0 kgf·m·s²)

58.8 kg·m²(6.0

kgf·m·s²)

Loads must be kept below maximum conditions shown in [Fig. 3.8~Fig 3.10].

[Fig 3.8] and [Fig 3.10] show the possible range in which a point load can be

positioned, assuming the attached load is a particle. However, as the actual load(End

Effector) is not a particle, calculate and evaluate the moment of inertia on each axis.

The following exmple shows moment of inertia calculation assuming the attached

load is a particle.

[Example〕An attached load weight is 200Kg with the 【 HX300 】Model

Allowable position of the center of gravity from the center of R1 axis

① Allowable position of the center of gravity from the center of Axis R1

L

R1

≤ (Allowable Torque) / (Load Weight)

L

R1

= 687 N·m / (200Kg×9.8 m/s

2

) = 0.35 m

② Allowable position of the center of gravity from the allowable moment of

inertia

L

R1

≤ (Allowable moment of inertia/ Load Weight)

1/2

= (30 kg·m

2

/ 200 kg )

1/2

= 0.387 m( > 0.35 m)

From the above result, the maximum distance from the center of R1 axis becomes

0.35 m, being restricted by the allowable moment of inertia.