HX200/HX200L-2000/HX300/HX300L/HX400

4-4

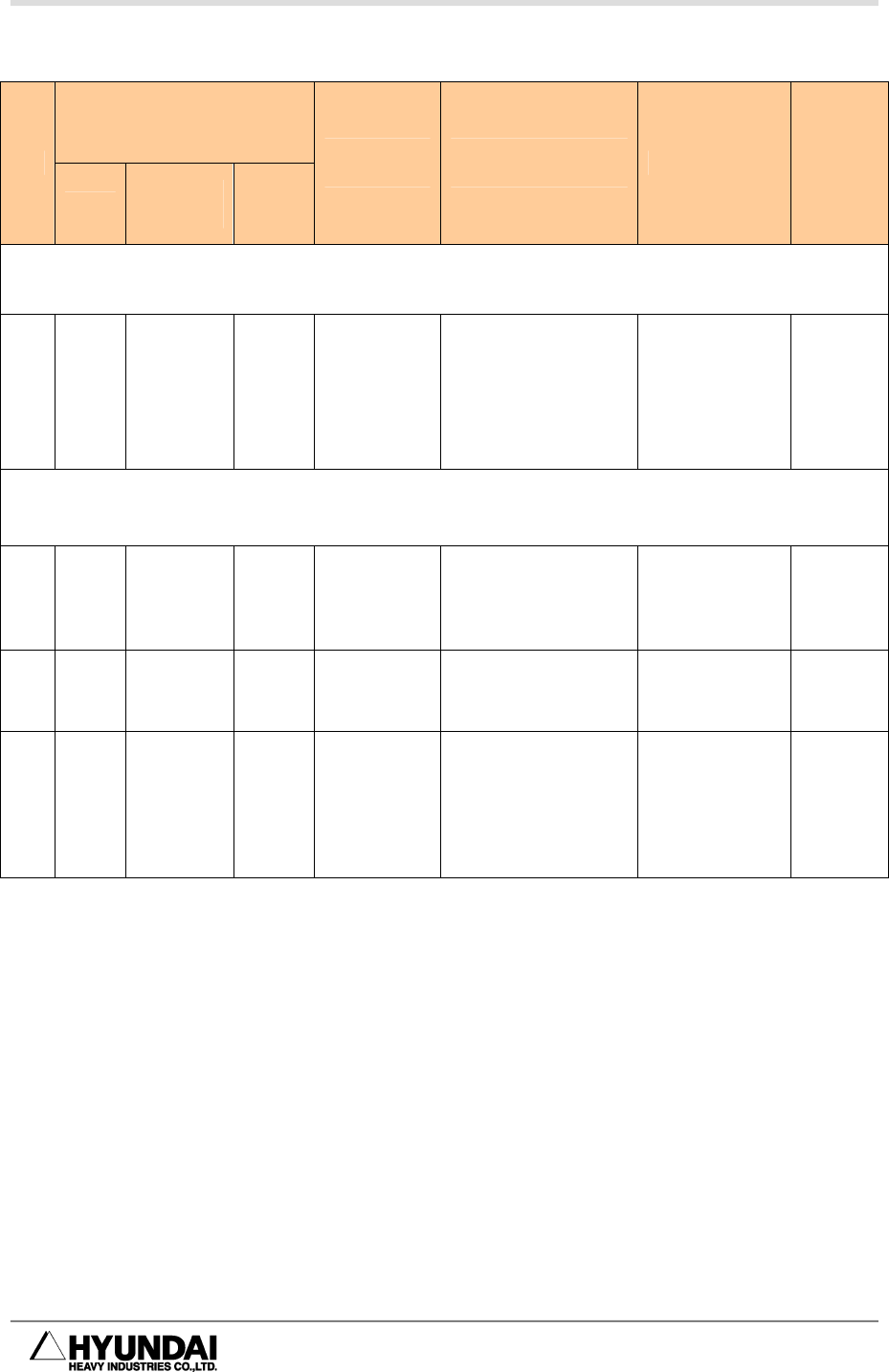

Inspection Intervals

No.

Daily

3

mothns

1

year

Inspection

Items

Inspection

method

Standards Remark

Axix S, H, V

7 ○

Reduction

gear

Check the abnormal

sound

Check the

shaking(vibrating)

Axis R2, B, R1

8 ○

Reduction

gear

Check the abnormal

sound

Check the vibrating

9 ○

End Effect

tightening

bolts

Examine paint

marking with naked

eyes

10

○ Diversion

there is any

diversion by rotating

each axis to the right

and reverse

direction

should not feel

diversion by

touch

If the robot is utilized in adverse condition( such as spot welding, grinding,

etc.), perform the inspection more frequently to ensure proper reliability of the

robot system

Inspect all visible cabling, and replace them if damaged.

Check the mechanical bumper devices for deformation and damage. If the

bumper or Dog is bent, replace it immediately.

Check the tightening torque of main bolts as shown in [Fig 4.1].

Check the abnormal noise in an automatic or teaching mode in order to

ensure the condition of power transmission(such as motor, reduction gear,

etc).